looking good mate!

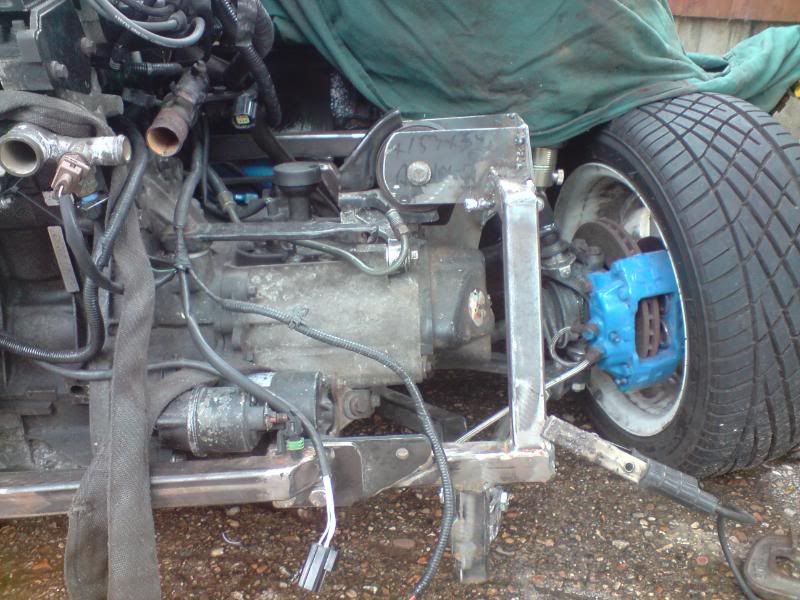

just a thought, why not fibreglass your front end around the k series subby... because it doesnt look like the shape would change that much, just have some other bulges... if you get me!?? lol

the longer fronts i always think look a bit odd... but looking at your super large wheels, that might help keep it 'in scale'

i'm rambling.... lol

yeah i know what you mean mate. i did consider just rebuilding the front to fit the k series subby...but my fibreglass-ing skills are rubbish lol

i've looked at the longer fronts for a while and seen a vtec mini around here. didnt really notice the length until it was next to another mini. plus it should allow me to keep the alternator in the standard place, should also give more room for a large rad...and possible oil cooler and intercooler in the future

the wellers are only 6x13s, but they seem to have a huge outer dish. was considering some 6x10s but not sure if it would mess up the gearing?