Hi all, now that the weather is actually tolerable up here in sunny Wick, I have again begun working on my beloved Mayfair.

I started off the work this summer with the intention of renweing all rear braking components, but when I went to the garage I was storing the car in, I noted that the clutch pedal was solid and, with a bit of aggro, it moved about 1/2 an inch before coming to a halt.

I had a look under the bonnet and found that the clutch slave cylinder was seized and the master cylinder was weeping slightly (just prior to me following suit).

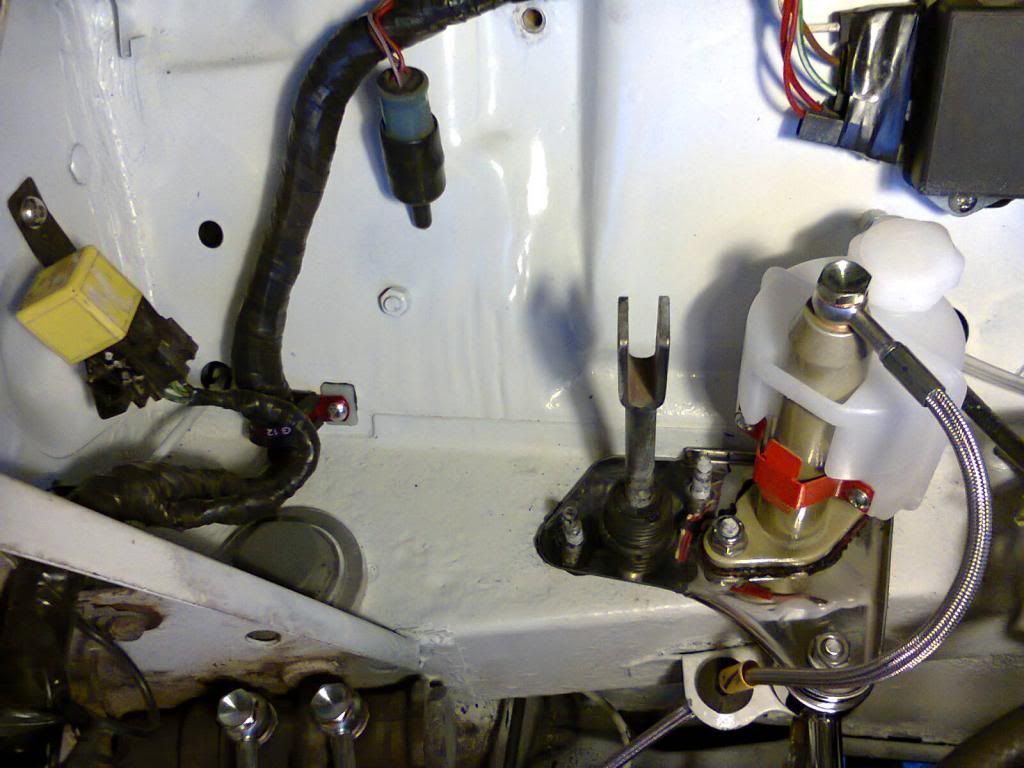

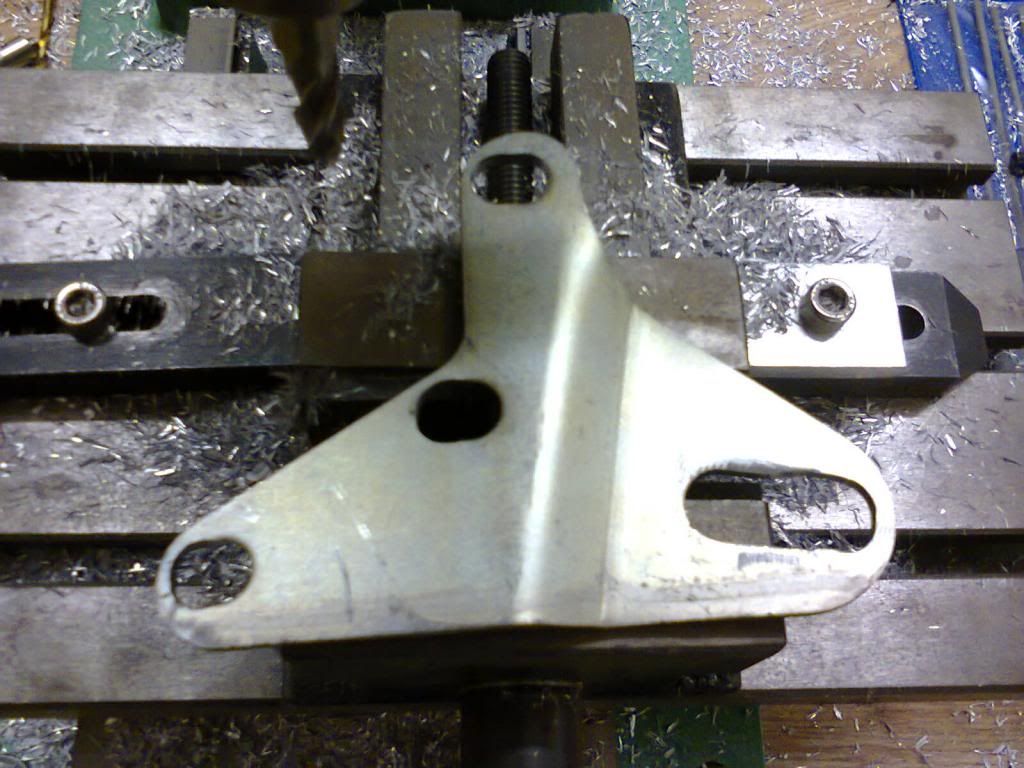

A quick stop online at one of the main Mini parts suppliers saw me get the two new cylinders, a braided hose to replace the aging and suspect-looking copper and flexi-hoses, followed by a stop off to get a stainless clutch master cylinder/ brake lever base-plate (plus gaskets) and clutch slave cylinder bracket.

After removing the clutch master cylinder, servo bracket and brake pivot assembly, I was greeted with this horrid sight:

The first thing I did was use IPA (a chemical I highly recommend for degreasing, cleaning and removing oxidation) to clean off all the surface ick and leave this:

This evening, after I borrowed a 3m vapour particle mask from work, I got my collection of wire-brush bits and drill and set about it, with these results so far:

I need to get a new, deeper cup-style brush and get more into those pedal box studs.

Quite want to replace the loom at this point as well, but that is quite a lot of work I'm guessing!

Edited by Jamieboy, 23 June 2013 - 03:48 PM.