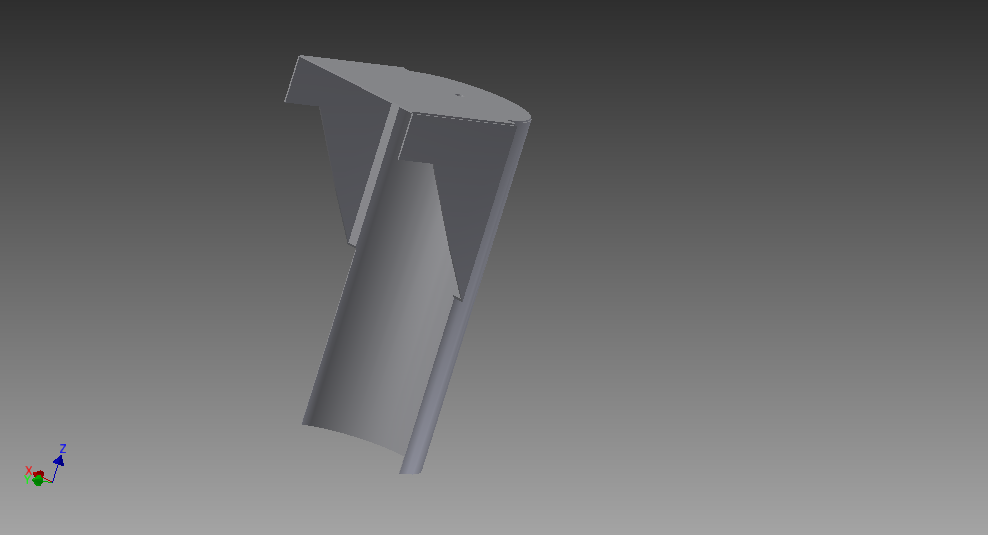

nahh not yet been bogged down in uni work at the minute when its done I will let you know. Ive still got to double check see if it still fits in with enough clearance. Through the measurements which I took it looks like it will have about 15mm clearance. with the gap of 130mm between the back of the block to bulk head. The big bit which will have to change is the actuator placement it looks like it will be mounted on the manifold with a heat shield and the mani being wrapped in exhaust wrapping. This has been done before but i'm still sceptical. If not there is a few other ways to do it. After the trail fit I will draw it up on CAD for you guys to see. Also be fore that I need to make and weld in the turbo plate. This is really the crural bit which I think will make it fit. All well it being tied in with zip ties but won't know till the end.

aup mate have you welded the flanges on your manifold now ? im thinking of making one but i don't have access to an engine ( well one that im not using that in the mini ) and was wondering what the measurements and angles are to make the gt17 fit without mods

cheers

Sorry missed this yeah I will, bought the elbow and going to make the rest out of 2" or might have to be 1.5"-1.75 to get past the pot joint.

Very nice mate, you making your own elbow and downpipe?

I'm probably going to have to reduce it.

Ive also worked out what sort of compression ratio I'm going to be running, depending on my pocket sizes wit could be 8.0-1 or 8.25-1 which will let me run up to about 12psi on the standard internals ect. So the pistons won't melt.

Nic

You can run more psi than that in 8-0-1 mate

At that it's like 25psi on the graph I have :L