Hi;

I am just finishing of doing the repairs in my boot and am about to do the sills Inner and Outer and front LH floor pan.

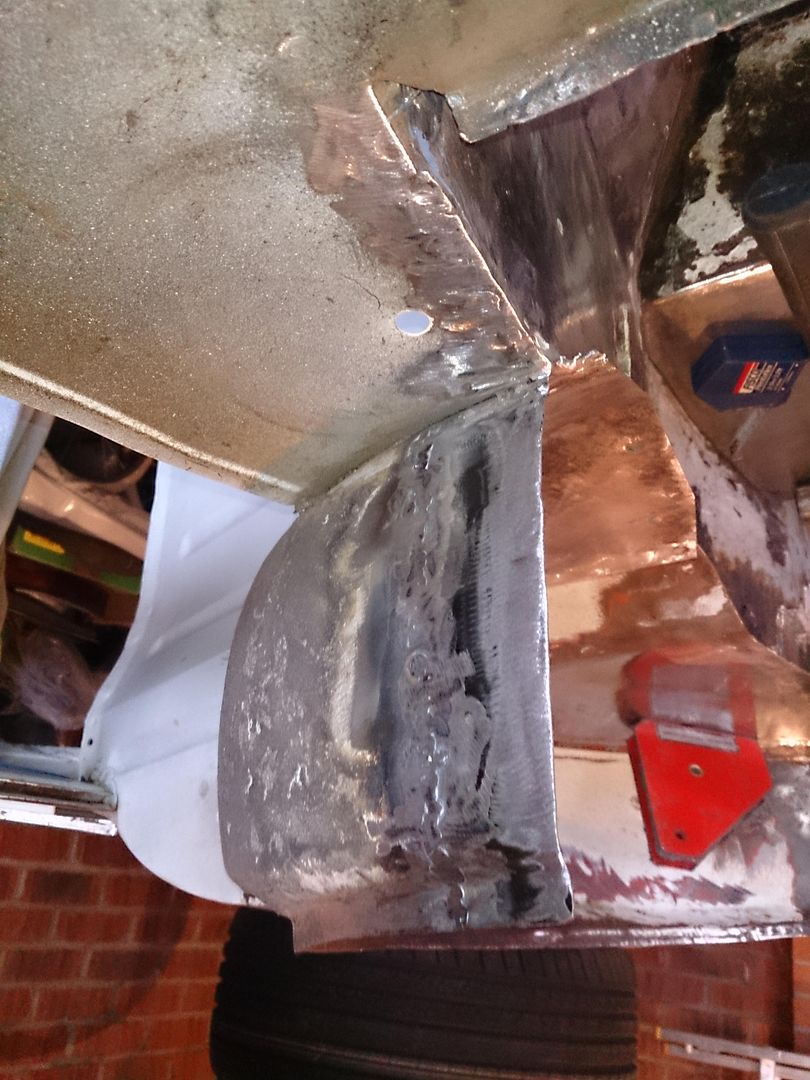

Inside the companion bin looks a right mess and is so rusted I am confused what's what, the Inner Sill Closing Plate has completely gone as has the rear arch up to and in line with the rear shock mounting point.

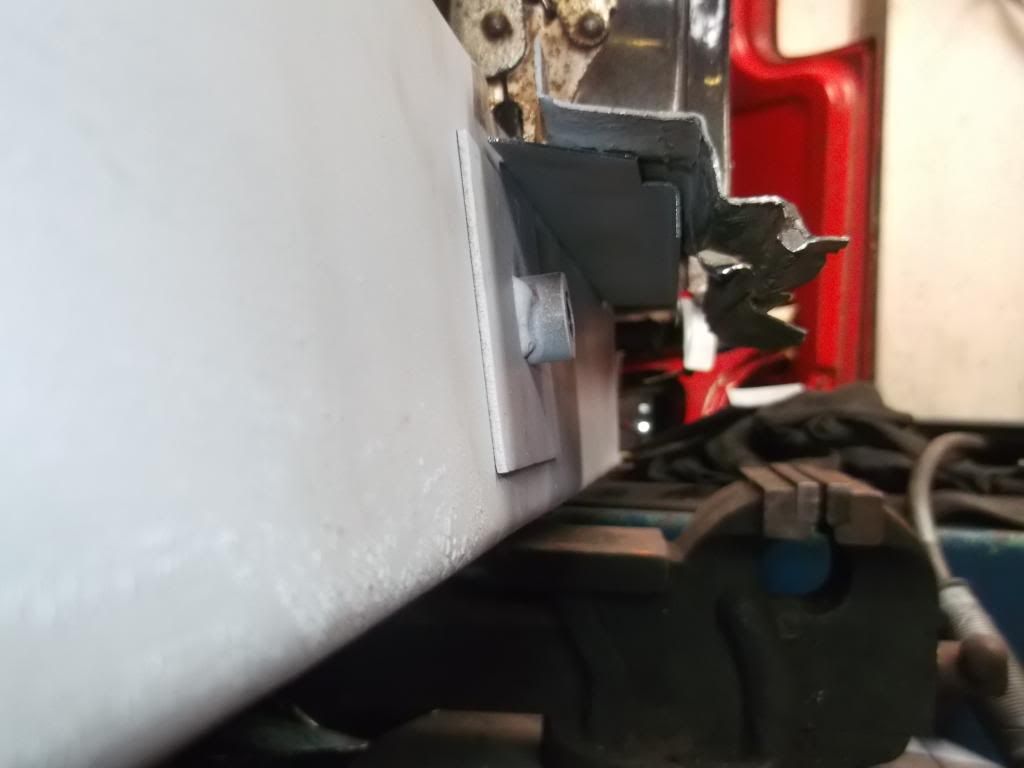

Here's the view towards the Heelboard (The gap on the RH side is where I have removed a previous repair that someone did (badly))

Here's the inside of the Companion Box looking down towards the rear:

Have I identified the various parts correctly? 1. Subframe Closing Panel. 2. Inner Sill Stiffener. 3. Is this the Inner Sill or part of the floor. Blue Arrow is this the Inner Sill?

There is a piece that has rusted away that I could not identify but remembered seeing an old post here which explains that it is an Inner Sill Stiffener.

I need some help working out how to facilitate this repair, i'll number the questions to assist in tying up the responses to the questions.

1. A previous post that I put up here mentioned that I should do the Heel Board first and then the sill but that was before I realised how bad it was behind the Heel Board, if I am repairing the Rear Arch (Less Shock Mounting SIde), Heelboard, Inner Sill Stiffener, Subframe Closing Panel, Inner and Outer Sill and Front Floor Pan what order should I do them in?

2. If I cut out all the above prior to repairing will I need to brace the passenger door, if so will one piece of Angle Iron welded horizontally half way up the door or will I require some other config?

3. Another thread I started on the Subframe Mounts and Heel Board repair here I stated that I was using Heelboard End Repairs with Captive Nuts Fitted (The ones without the Inner Sill Brackets). I was advised to fabricate a bracket or buy brackets from M-Machine, these ones:

11.32.02.27 Bracket, Rear Sub Frame Mounting with captive nuts, LH

11.32.02.28 Bracket, Rear Sub Frame Mounting with captive nuts, RH

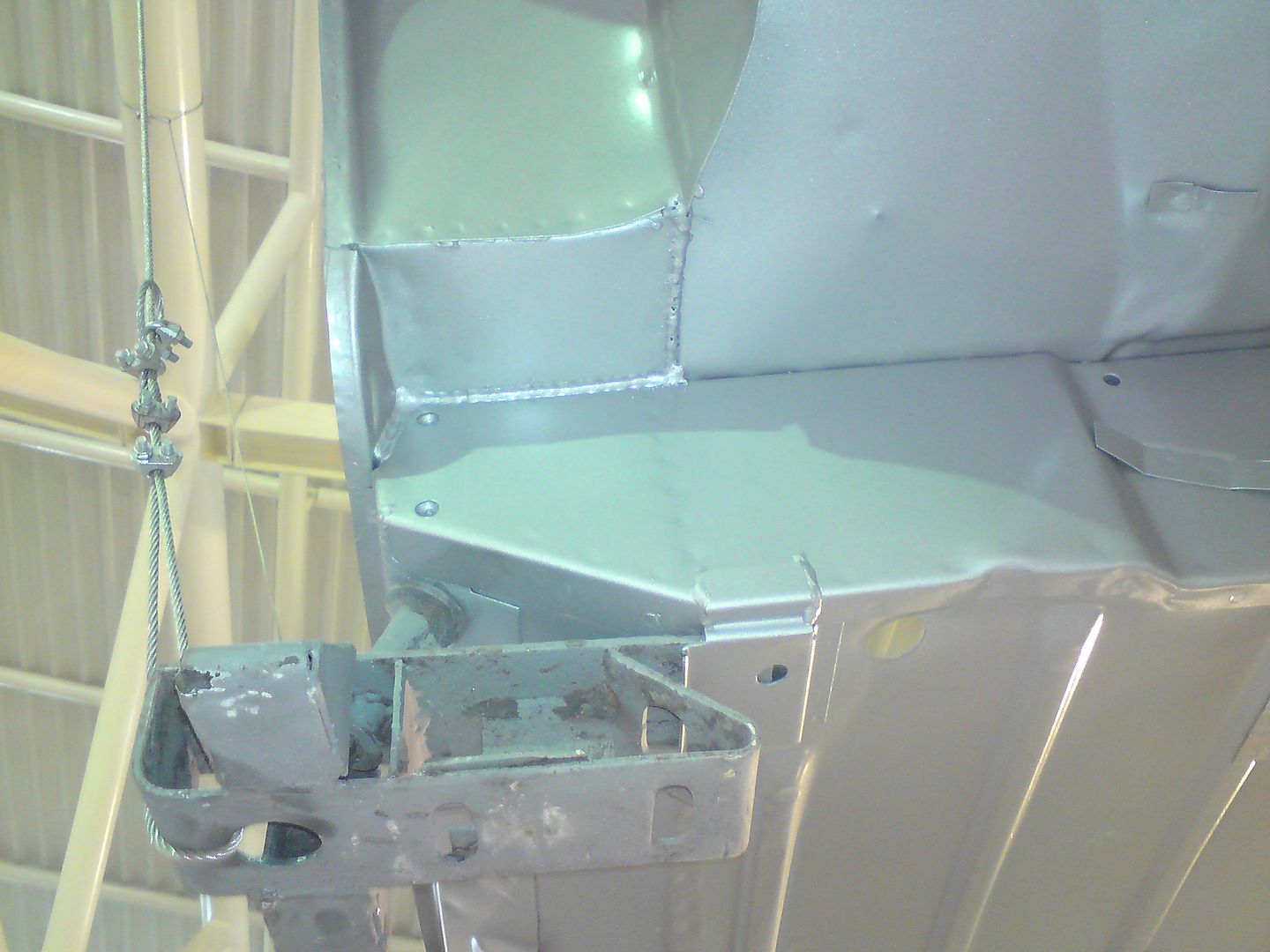

I guess these are visible once the Sill is removed?

4. I was also advised on replacing keeping the Slinging Shoe Brackets however never found out what they where or what they looked like?

4. To facilitate the repairs to the Heelboard, Inner Sill, Outer Sill, all the bits inside the companion bin and to get better access to weld the Rear Subframe with Captive Nut Bracket in place I will need to cut out / off the bottom half of the skin that sits below the rear passenger window, if so is this the repair panel (M-Machine 11.14.10.07 Arch to Door Repair, LH)? Or how much should I cut out?

Here's the rear end, the part that may need to be cut out has already been filled so its probably in a state underneath??

Thanks for reading.