So its time for a massive update!

Since the last update I have reached a milestone and the floor is now in the car, but more of that later on.

So I started on the passenger side doorstep again. Got the panel primer with weld through primer and the holes for plug welding drilled:

The A post was also cleaned up with deox gel and primed ready for welding:

Got it welded in place:

Then I removed the boxing plate and cleaned up the back of the door post again using deox gel and primed:

I then welded the new reinforcement boxing plate to the door step:

Then I moved onto the floor. I decided to weld the companion bins and closing panels to the floor along with the seat cross member before I welded the floor into the car to help with access.

I started off by trial fitting the new LH companion bin:

Then primed the floor where the companion bin is to be welded to:

Then got it welded onto the floor:

Then I trial fitted the new closing panels:

Then primed and clamped ready to be welded:

Then welded into place:

Then moved onto the RH companion bin and closing panels:

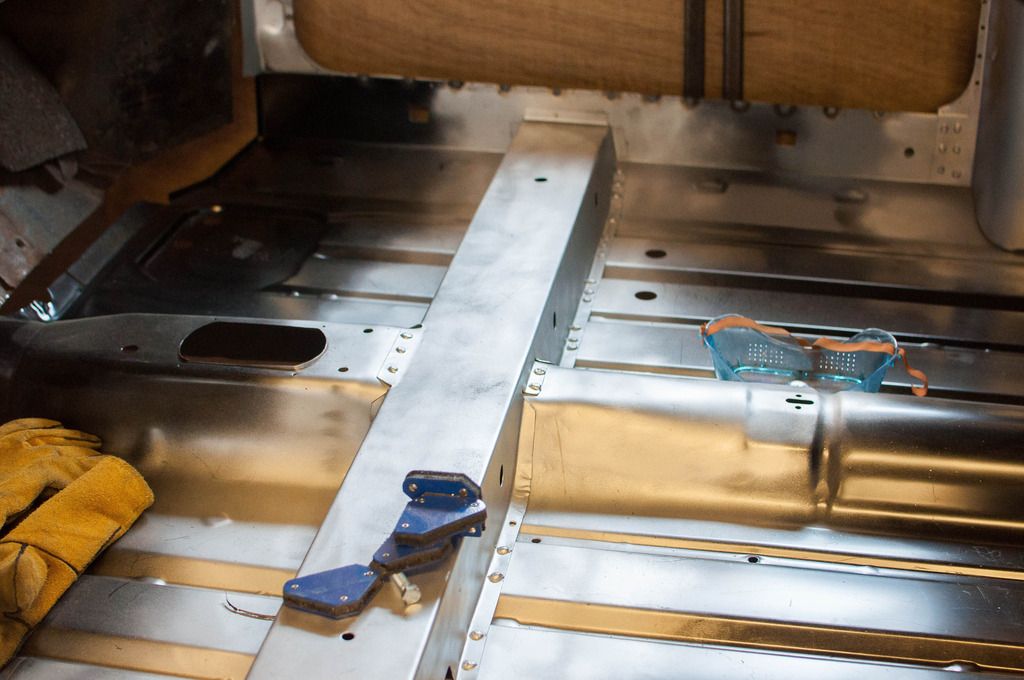

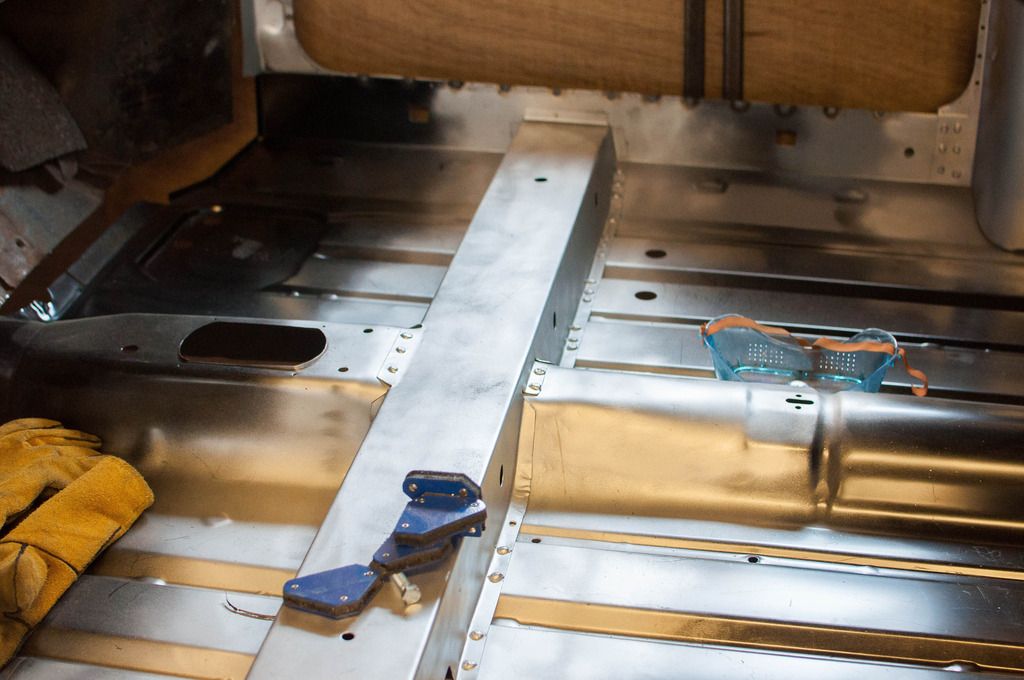

The next stage was fitting and welding the floor cross member:

Then came the exciting point of fitting the floor into the car. Firstly I ordered some new alloy trunnions for the rear subframe from DSN and a rear subframe mounting kit from Mini Spares. I then trial fitted the rear subframe to the floor and to the boot floor to get the exact position for the floor to make sure that the subframe fitted correctly.

I then got the floor welded to the door steps and up the B posts:

I then turned my attention to the LH flitch panel. This is what it started out like:

Got the old panel cut out:

And the post cleaned up and primed. Then started about welding the new repair panel in:

Still have a little more tidying up to do at this side but its a vast improvement on the old panel.

Well that's all the progress to date, I'm going to try and keep this more frequently updated in the future.