Well hello all!

Seeing as the Mini my brother and I bought in August last year is slowly turning into a bigger job than originally anticipated (well who'd have thought with an old Mini...) I thought I would start a thread on here to show the (most likely slow) progress as we begin to restore her as best as possible.

This is my second Mini after buying my first aged 14; but this will be my first proper restoration and rebuild. Little bit daunted but seeing the great threads on here I am sure there will be plenty of info and help to hand :)

So, the mini:

It's been a slow start for various reasons but we have finally got round to stripping the Mini down to a shell, subframes and engine. The plan being to fully strip the running gear, subframes etc. and get as much refurbed and probably powder coated, replacing where needed and initially just give the engine a tidy up and run a few tests. (we may fully rebuild the engine along the way but for now as a runner, it's not on the cards).

Due to the limited space in the "workshop" we have raised the shell up onto breezeblocks and I-beams for support to make the height for welding more bad-back friendly!

As you'll see, we have started at the rear, with the plan being to rotate the shell by 90 degrees after the rear is done, making access to the sides easier.

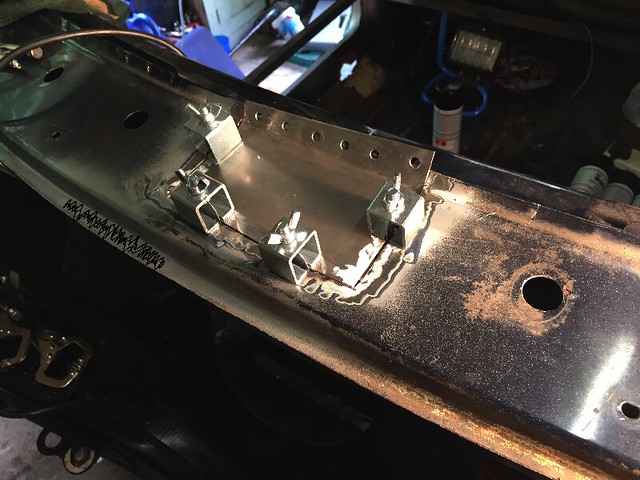

We began by chopping out the rear valence to reveal the infill panels and we have also started to unveil the rust holes in the boot floor and rear arches. (Suggestions welcome at any point)

I plan to remove the infill panels as they are a little corroded as well as chop out the rot in the floors then replace both of these before fitting a new rear valence.

Once this is done, i.e welded, what's the general advice on painting, sealing etc. whilst the other bodywork is undertaken? I have seen threads using Tiger Seal and just a Zinc primer?

Anyway, I'll let some photos do the talking now....

Edited by henryS, 02 June 2015 - 07:48 PM.