Oil Pump

#16

Posted 04 September 2015 - 01:39 PM

#17

Posted 04 September 2015 - 08:44 PM

Hmm cheers the the replies guys! Think I might just keep the current one in then as there's nothing wrong with it I was just going to change it while I was there

Well, at least it's tested!

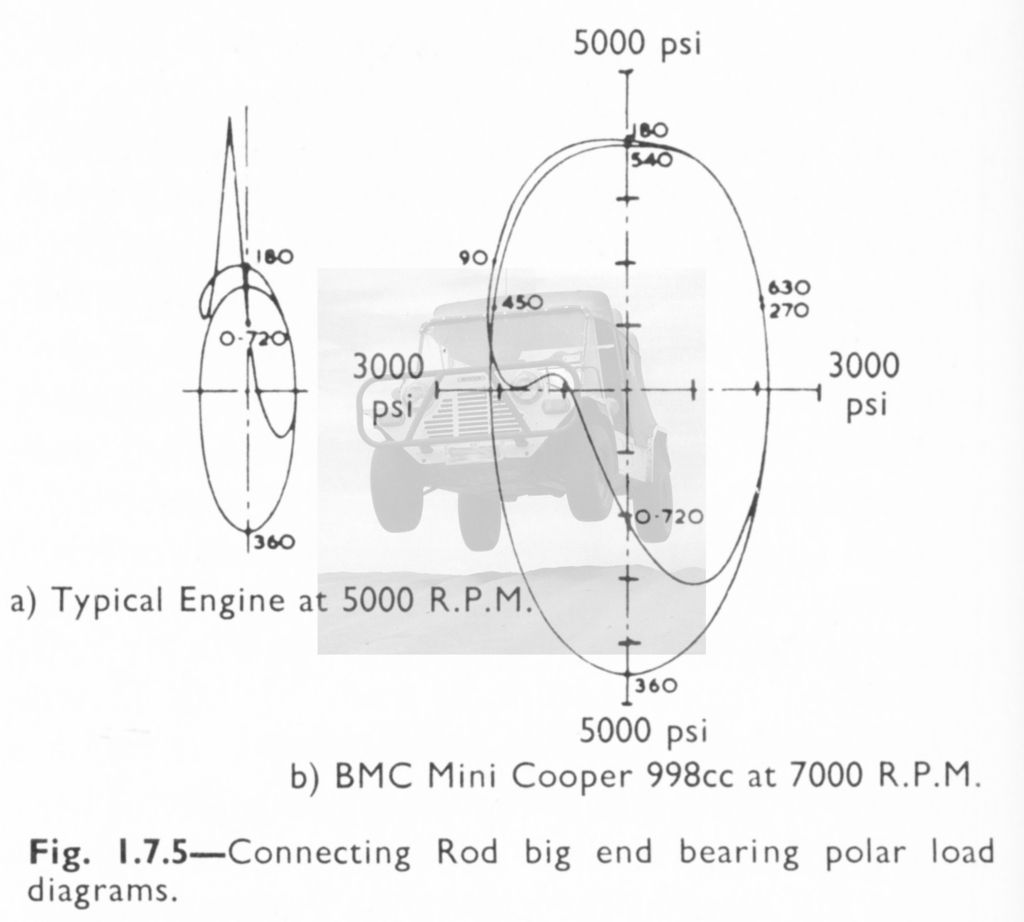

This is the Load Polar Plot I mentioned earlier (yes, I rememberd) - Dusty - I think you'd also be interested in this, I mentioned it to you before;-

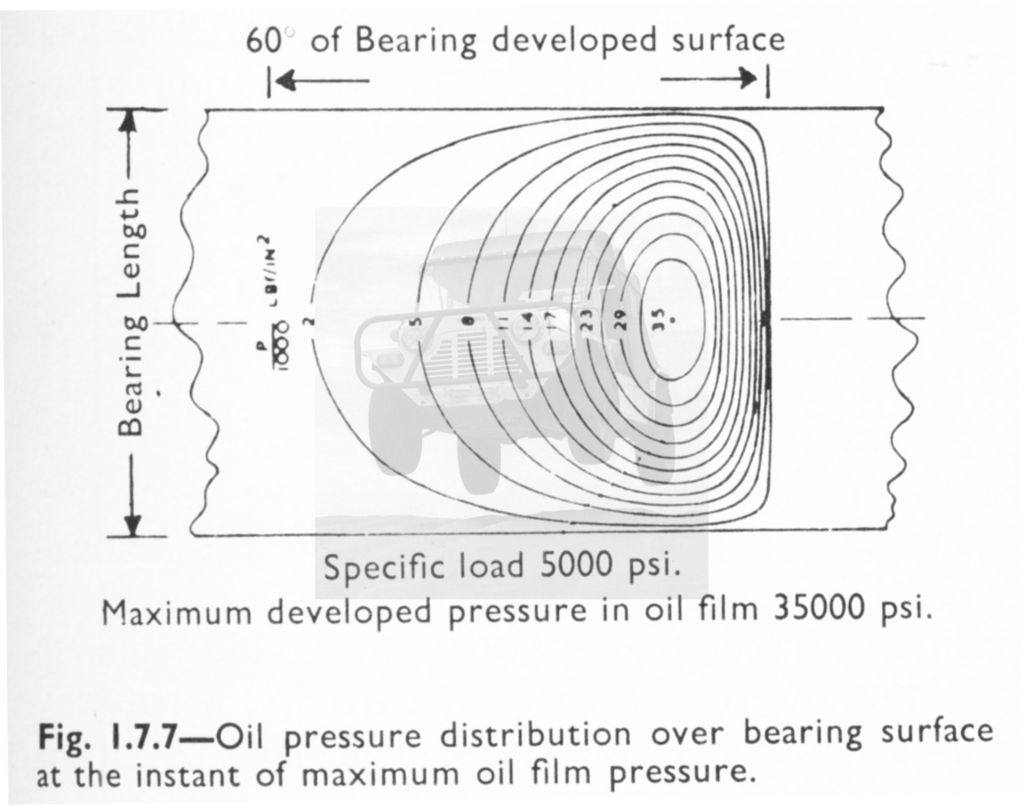

and this shows not only how much of the Bearing Shell is doing the work, but how the load is distributed on to the Shell, you'll see the spot pressures are very high, much higher than any Oil Pump would ever hope to match!

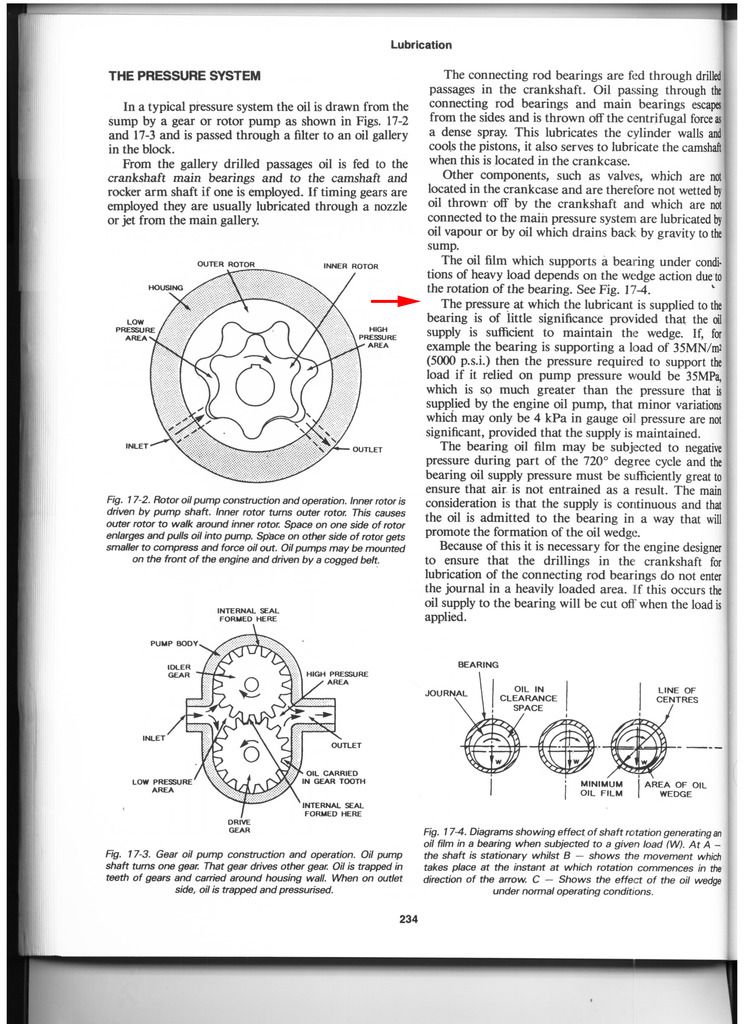

while looking for the Polar Plot, I found this in an Engine Design Manual, interesting what is said about Oil Pressure (the Arrow is mine)

#18

Posted 10 May 2018 - 03:58 AM

There was a mention of some A+ pumps being too long. I believe that is what I have.

I fit the camshaft and it sticks out too far. The locating plate locks it in tight, so it won’t tun.

Does anyone have a fix for this? I thought about filing down the slot drive a bit to make it fit. Seems like the simplest solution.

Thanks for any info!

Scott

#19

Posted 10 May 2018 - 05:25 AM

#20

Posted 10 May 2018 - 01:26 PM

Interesting to see some figures on the pressures in the bearings, baffles me how it can be so high but the feed pressure is so little...guess its just that its the very thin oil film on the load side and the pressure is localized...?? and the load side must switch round with the firing order and stroke.

It is down to flow, rather than pressure, I always do the oil galleries in any high performance motor...by that I mean take all the sharp edges off at the oil pump block face holes and the oil filter head to block hole. I also take the top sharp 90 degree edge off the inside of the outer ring in the pump, all the oil has to flow over it twice.

The small gallery from the pump to the block is also a restriction, with sharp 90 degree corners it feeds the entire engine, the drag must be huge. It runs across to the relief valve, I drill it 1 1/2mm bigger, which will flow about 30% more, the same applies to the gallery from the 5/8th UNF banjo bolt down to the cross gallery and the one from the oil filter head up to the main gallery. Use a -8 braided transfer pipe, cut 2 coils off the relief valve spring (use a ball) and an adjustable knob.

I also flow the oil pumps the ally casings have 90 degree steps 2 in and 2 out, (take them all off by hand).

It should save power winding the pump round as it reduces the drag greatly and reduces the heat enough that most don't need an oil cooler.

#21

Posted 10 May 2018 - 06:57 PM

Retroman - that's a really good picture showing where several of the mission critical oilways go... must have needed a steady hand with the hacksaw.

#22

Posted 11 May 2018 - 01:50 AM

Doesn't happen to be a cross drilled cam does it? If it is theres been a couple of posts on here where the ball bearing blocking the drilling in the end of the slot drive protrudes too far and causes the cam/pump to bind once the triangular plate is fitted. Think one was possibly a swiftune cam.

Thanks for letting me ride this topic.

It is a Kent cam if that helps. I hate to say I don’t know much beyond that. Both pump and camshaft are new from Mini Sport.

There is a small hemisphere in the slot end of the cam, but I am pretty sure I can file down the male end on the pump much more acurately.

Any advice is greatly appreciated.

Scott

#23

Posted 11 May 2018 - 04:38 AM

Thanks for letting me ride this topic.Doesn't happen to be a cross drilled cam does it? If it is theres been a couple of posts on here where the ball bearing blocking the drilling in the end of the slot drive protrudes too far and causes the cam/pump to bind once the triangular plate is fitted. Think one was possibly a swiftune cam.

It is a Kent cam if that helps. I hate to say I dont know much beyond that. Both pump and camshaft are new from Mini Sport.

There is a small hemisphere in the slot end of the cam, but I am pretty sure I can file down the male end on the pump much more acurately.

Any advice is greatly appreciated.

Scott

Sounds like yours is cross drilled.

I don't know how to link a post but if you search "camshaft issues" there is a post with the same problem you have where the ball bearing oil gallery plug isn't set deep enough into the cam and causes the oil pump drive to bottom out in the slot. Cam was considered faulty by swiftune and replaced

Edit: This thread http://www.theminifo...camshaft-issue/

Edited by Moke Spider, 11 May 2018 - 05:35 AM.

#24

Posted 13 May 2018 - 04:00 AM

Sounds like yours is cross drilled.Thanks for letting me ride this topic.Doesn't happen to be a cross drilled cam does it? If it is theres been a couple of posts on here where the ball bearing blocking the drilling in the end of the slot drive protrudes too far and causes the cam/pump to bind once the triangular plate is fitted. Think one was possibly a swiftune cam.

It is a Kent cam if that helps. I hate to say I dont know much beyond that. Both pump and camshaft are new from Mini Sport.

There is a small hemisphere in the slot end of the cam, but I am pretty sure I can file down the male end on the pump much more acurately.

Any advice is greatly appreciated.

Scott

I don't know how to link a post but if you search "camshaft issues" there is a post with the same problem you have where the ball bearing oil gallery plug isn't set deep enough into the cam and causes the oil pump drive to bottom out in the slot. Cam was considered faulty by swiftune and replaced

Edit: This thread http://www.theminifo...camshaft-issue/

Exactly what I was looking for. I may contact Krent an see what they say. Looks like someone suggested grinding the oil pump as well. I will see what Kent says first.

Thanks for tracking that down for me!

Scott

0 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users