Back again. I seem to have done nothing but TIG weld recently.

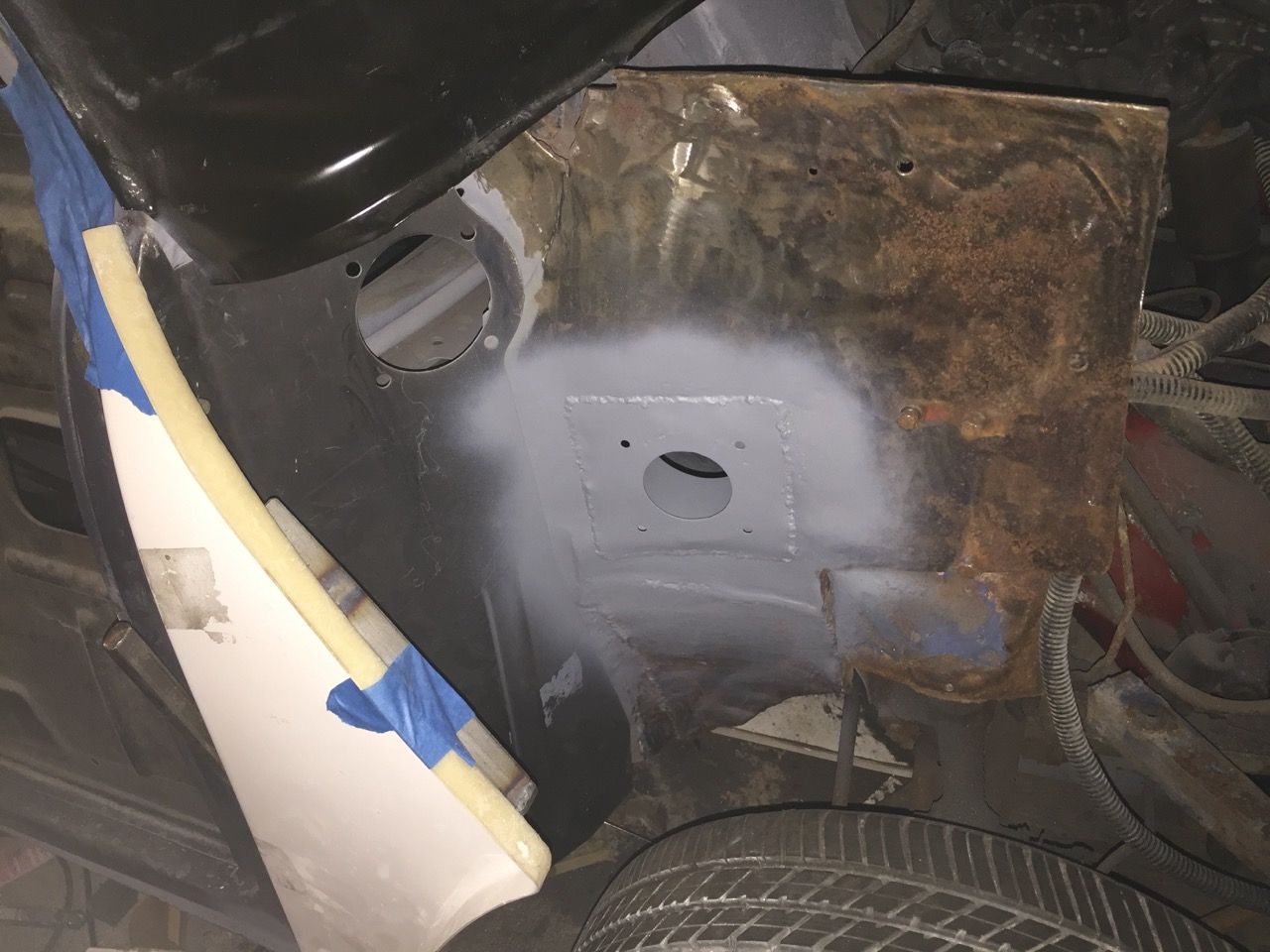

O/S is now all welded up and only needs a sill and jacking mounts to complete.

Here is the O/S all welded up and just needing a sill as the last panel and some jacking mounts. I have also fitted the fibreglass A-panel into its 304 stainless steel frame.

I an still designing my front shack mounting as I think I will make it integral with the front subframe mount support. More to follow on that at a later date.

While I was turning the car around I also did a first fit on the fibreglass rear doors. They are not the easiest thing to fit. Here they are just needing a bit of squaring up.

So that is 2 doors down 2 to go.

Here is my reskinned O/S door using a genuine heritage part. I have to say it was far easier to fit than I had imagined. I put the skin on with plenty of panel sealant so that as I crimped the flange it all oozed out nicely. No chance of water getting in that joint.

The N/S door needs a repair to the bottom. It looks like someone reskinned it in the past and did a poor job of protecting the metal so the tin worm won.

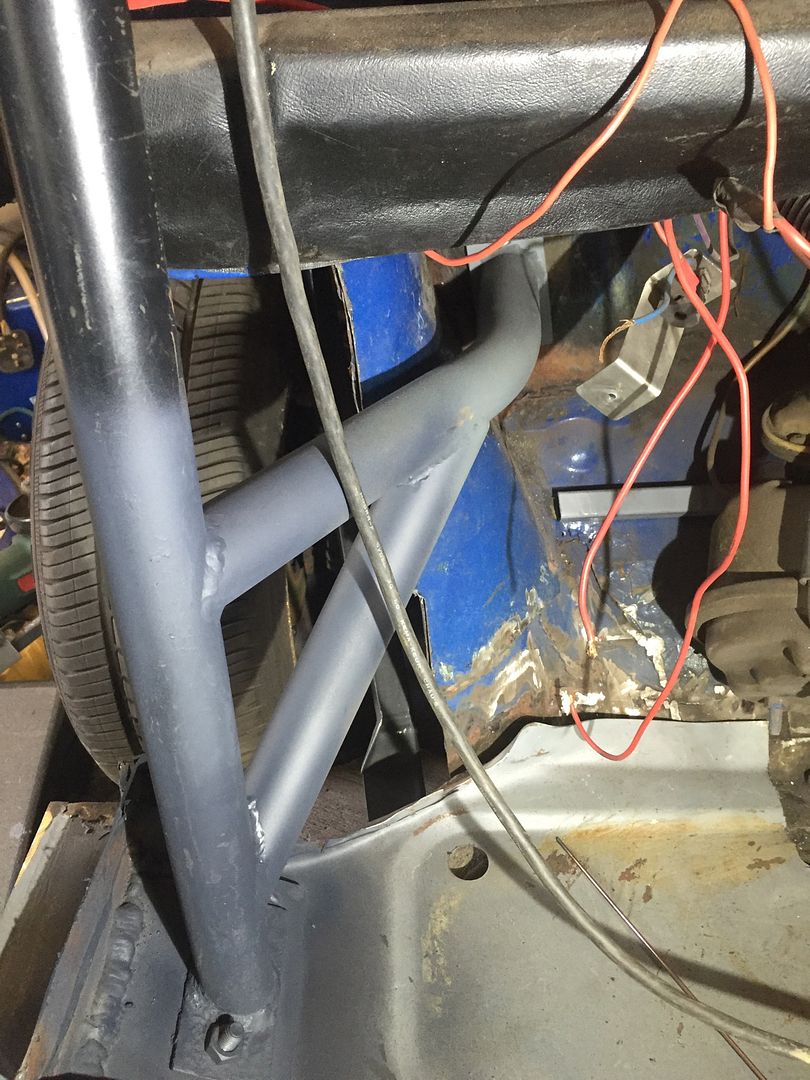

So car turned around again and only the N/S door pillar, inner wheel arch and floor to fit; oh and a roll cage mount and a windscreen scuttle and an A-panel and a door skin and close the rear side,.......................and door bars and harness bar and cage diagonal....................and the shell is finished!

Time for a stiff drink!

Edited by Itsjustanestate, 26 October 2016 - 07:52 PM.