Mcmini Micra Conversion

#181

Posted 08 January 2017 - 05:25 PM

#182

Posted 10 January 2017 - 10:45 AM

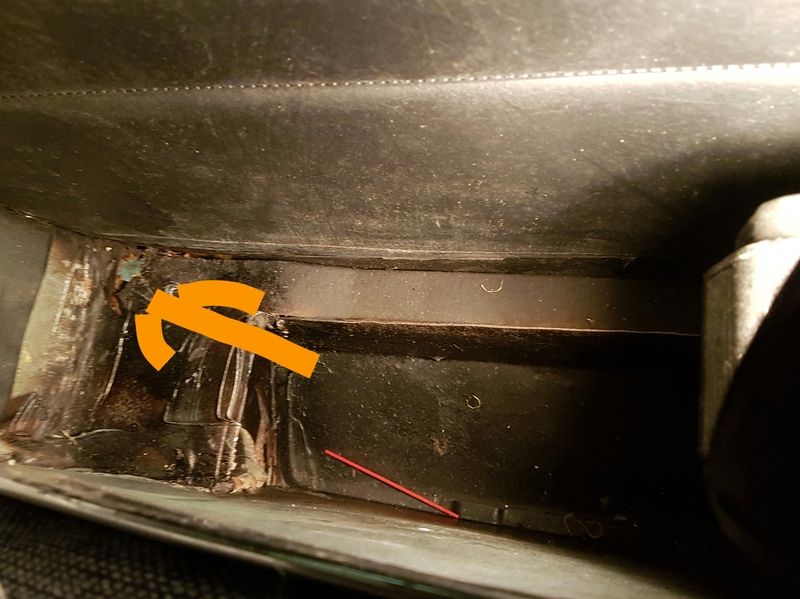

I got the subframe out last night and it's not good news -

This is further gone than I was hoping. I could repair it but it's the rust in all of the bits I can't see that's putting me off. So it's time for a new one and a £200 bill that I was not budgeting for! I take it after-market ones are OK? I'm not shelling out £450 for a genuine one as for that amount I would rather make a tubular one.

On the plus side the floor is in remarkable condition and is all original. Heelboard looks in good shape.

Only a couple of spots of surface rust on the boot floor where the exhaust has degraded the rust protection. Check out how rust free that back panel is!

#183

Posted 10 January 2017 - 10:41 PM

That's what I did for mine before confirming it was dead. It's worth a look either way :)

#184

Posted 11 January 2017 - 11:12 AM

#185

Posted 11 January 2017 - 05:42 PM

Could be worth you taking one side of the rusted bit off then you can inspect the webbing on the inside also?

That's what I did for mine before confirming it was dead. It's worth a look either way :)

The web is definitely rusted and has holes in it. I could cut out all the rust and replace with sound metal and I'm confident it would be strong and I'd make a good job. The problem is the rust that you can't see. In the seams and triple sections. Even sandblasting won't get that out. A new one has been ordered with fitting kit and also new radius arm pins and bearings.

What about a rear beam subframe and trailing arms with coil overs? If it's the back section that's corroded then may be able to use the front where it bolts to the heal board.

I did think about making a beam. However, I want to keep the suspension standard (well rubber donuts and hilos). I also want a tow bar on it so the only option for fabricating something would be a full tubular subframe. I would use square bar if I was making something up. Maybe a project for the future (maybe even a sideline business!) but time is marching on and this build is not going as fast as I would like.

My new subframe will be stripped of the paint it is supplied in and painted with Epoxy Primer and then a coat of 2K black. After that it's waxoyl or dynotrol all over and in the box sections. As this car will be more or less a daily driver I am doing my best to slow down the return of the inevitable rust that seams to love attacking our wee Minis!

#186

Posted 11 January 2017 - 06:36 PM

#187

Posted 11 January 2017 - 06:47 PM

#188

Posted 11 January 2017 - 08:17 PM

Just seen this looks very good like the look of the subframe 👍

Cheers. If only everyone appreciated my engineering abilities! Long story.

#189

Posted 11 January 2017 - 11:09 PM

#190

Posted 12 January 2017 - 09:33 AM

I cut the subframe to get access but it is impossible to get a socket on the nut as there is another captive nut in the way. I managed to wedge a 13mm crow foot spanner in there and luckily the bolt sheared.

#191

Posted 12 January 2017 - 07:19 PM

Chisel off and weld a new one on! ive converted my rear subframe to all metric fittings ![]()

#192

Posted 13 January 2017 - 10:45 AM

Chisel off and weld a new one on! ive converted my rear subframe to all metric fittings

Definately a good idea Ben. Im slowly turning everything I can into metric on the beastie.

#193

Posted 13 January 2017 - 10:52 AM

Chisel off and weld a new one on! ive converted my rear subframe to all metric fittings

Definately a good idea Ben. Im slowly turning everything I can into metric on the beastie.

Yes but not a good idea if I'm fitting a new subframe!

Radius arms are in work with me today as I need the oxygen acetylene on the brake adjusters.

#194

Posted 23 January 2017 - 11:55 PM

I started scraping the rustproofing off the underside. It's taking ages. Found some holes that need a bit of welding. It's that bit where all the muck sits on top of the subframe.

This is it from the inside. The inner sill looks mint except for this one wee bit.

1 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users

-

Google (1)