Hi guys I thought I’d start a build thread for this even though I won’t actually be working on the car for some time yet. I’m currently looking to buy my first house and my mini is in storage so won’t able to start on it until that’s sorted. Once the house is sorted I’m hoping this will move along quite quickly, however at the moment I’ve got a few bits I’ve made I thought it was worth documenting hence the thread.

So the plan is to build a mild miglia style track car that's still road legal. Even though it will most likely be trailered to events I still want it road legal so I can do the odd Sunday drive and take it to meets and shows. I’m expecting to have to compromise in certain aspects to make it drivable on the roads however it will mainly be track based.

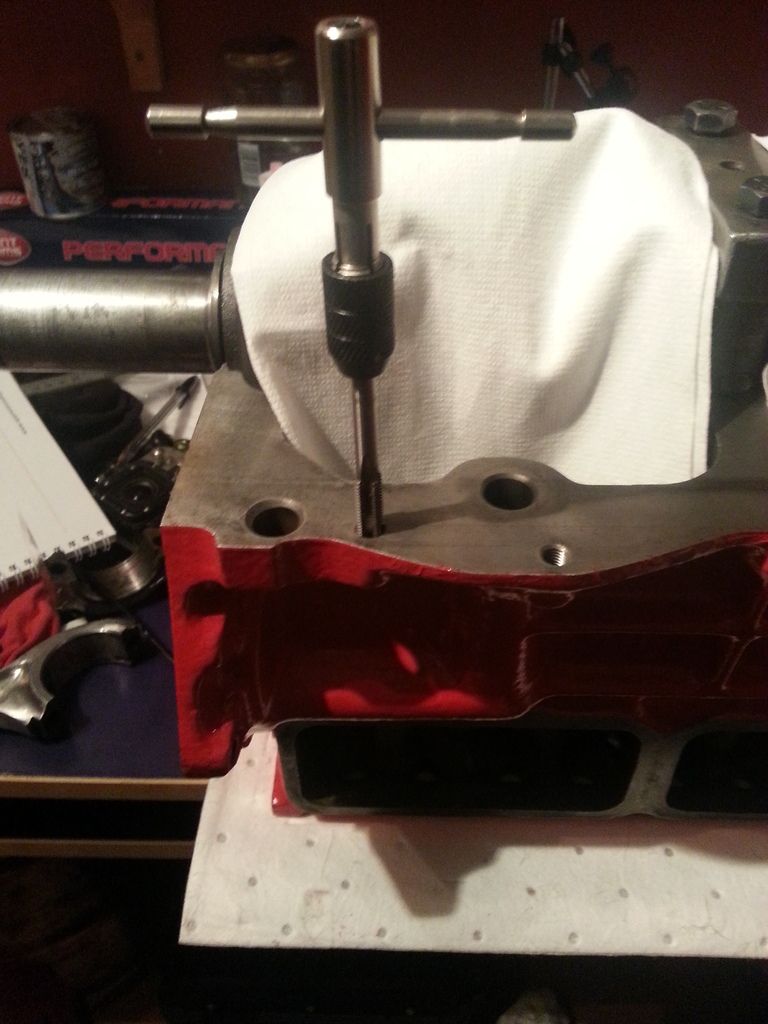

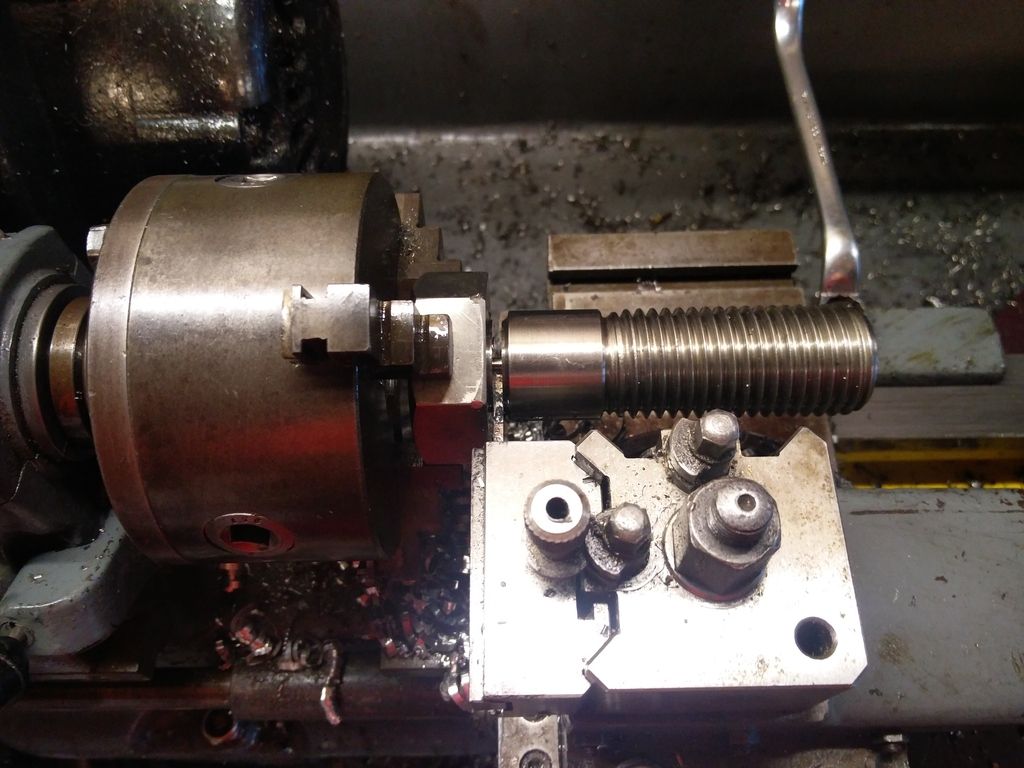

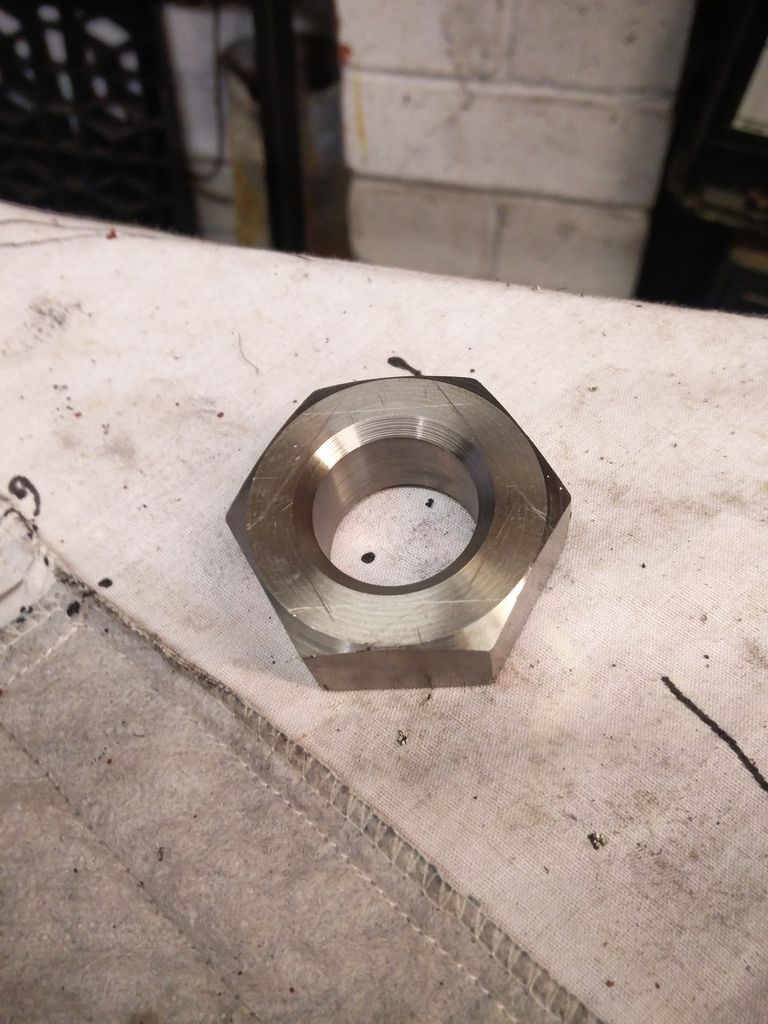

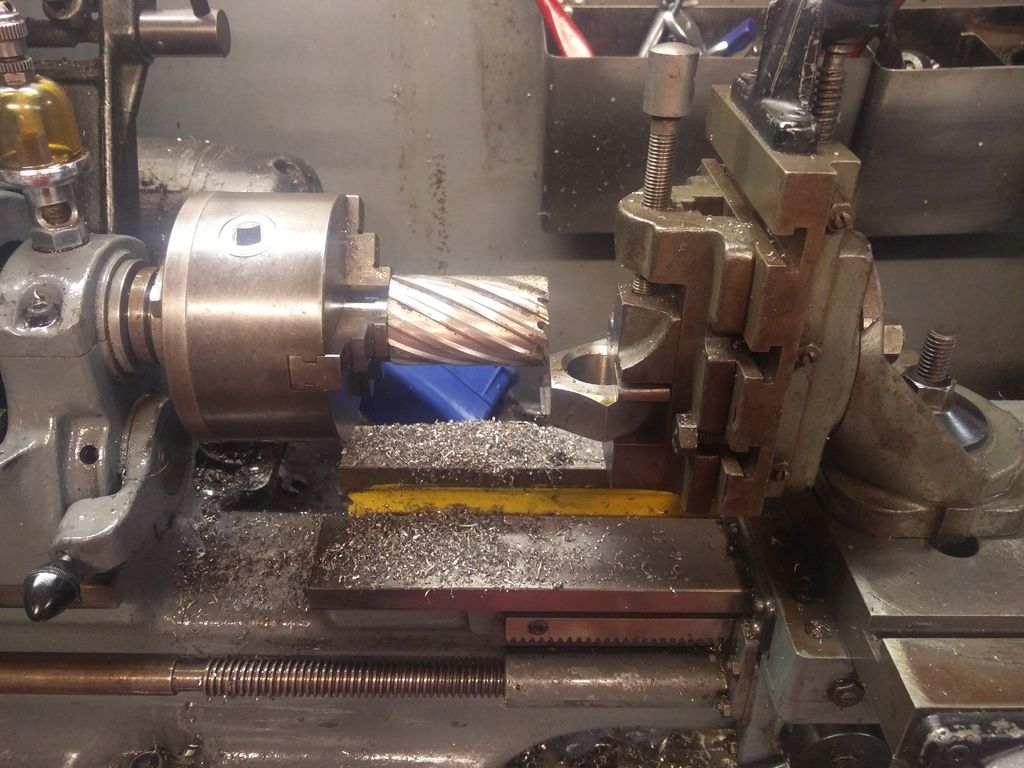

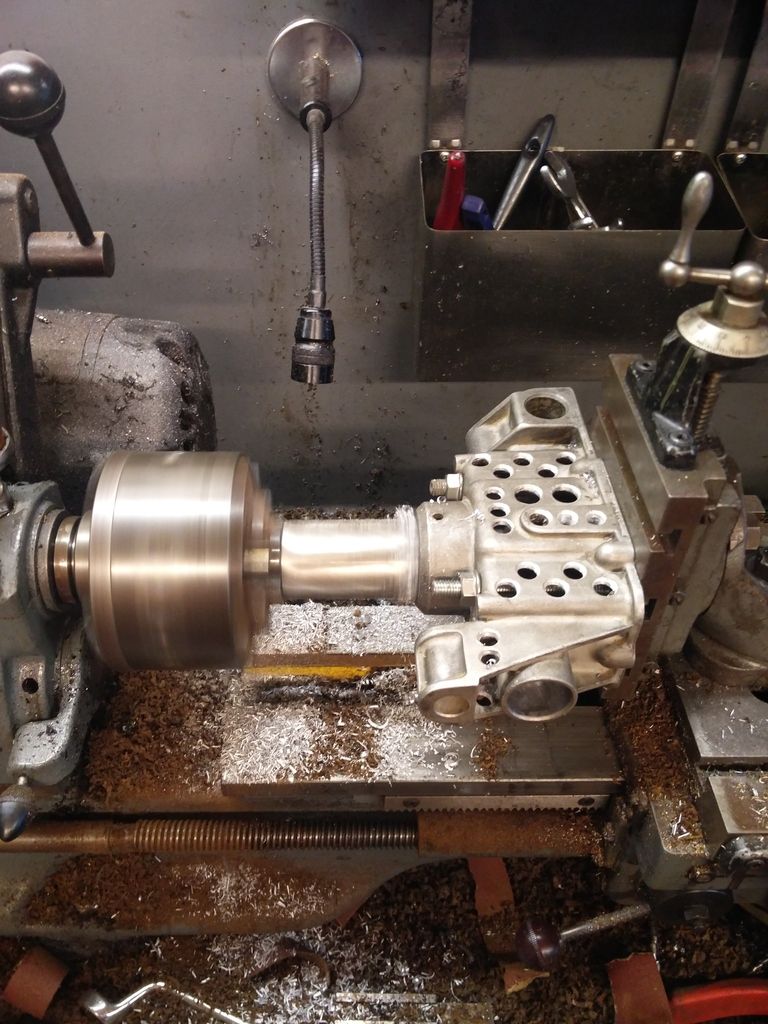

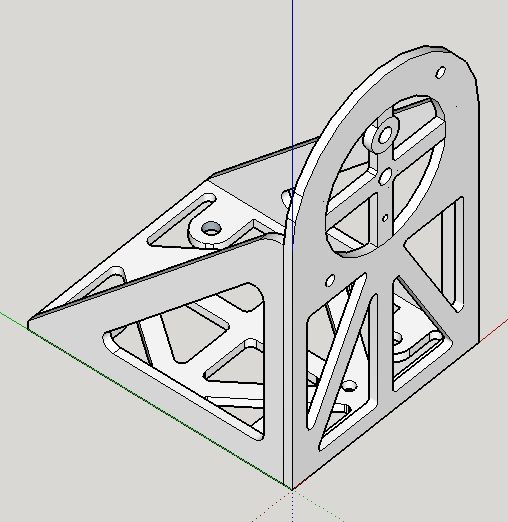

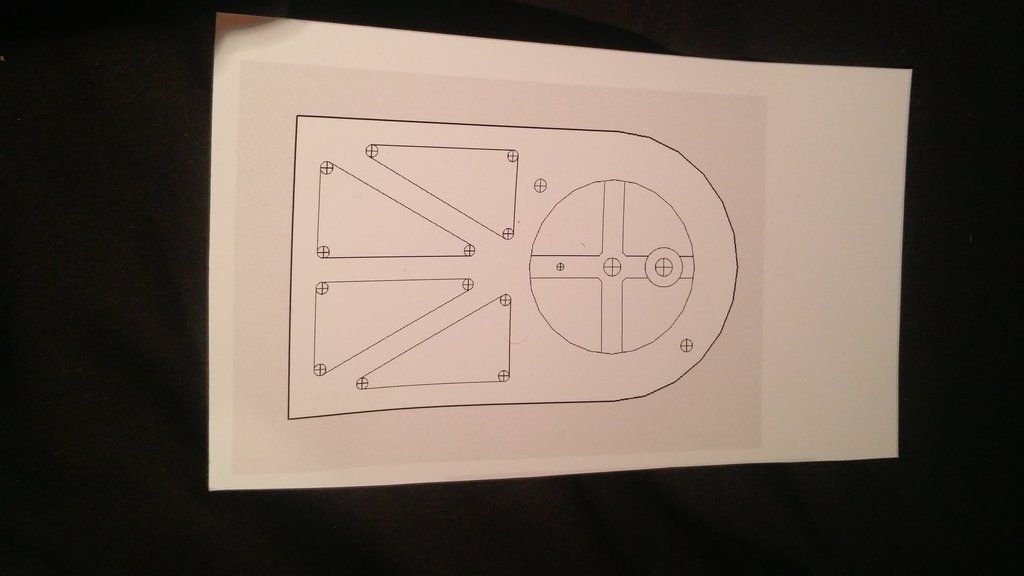

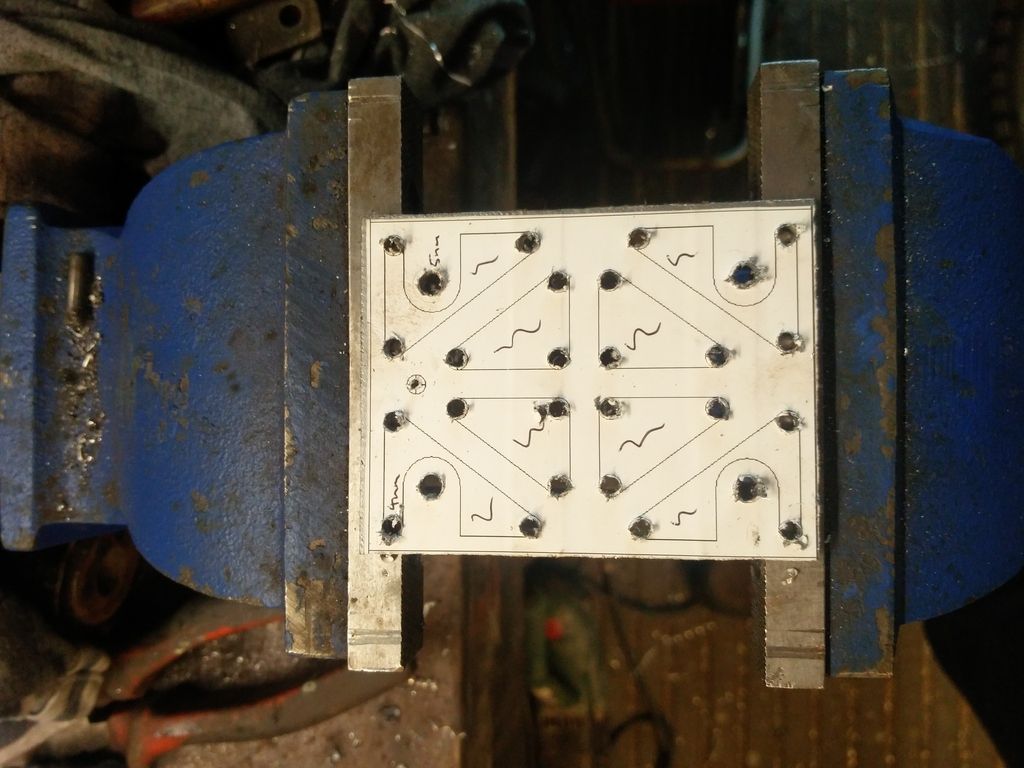

Styling wise I’ll be going for carbon miglia arches, roof, front end, and boot, 10” force racing split rims. Then totally stripped out with a full cage, bucket seats, harnesses and other than that everything very minimalist. I’m wanting to get it as light as possible but I’m going to try and not get carried away with it (this may have already happened). The whole plan with this project is to build something to the absolute best of my ability with no real restraints on cost or time (within reason), and if I can make a component as good or better than buying something I’m going to make it.

The car I’m starting with is my 1990 British racing green I’ve owned it about 8 years now and was my first car.

Edited by patto, 27 April 2020 - 09:28 PM.