Once again thanks for the comments and views, as can be seen the condition of the body work

never ceases to amaze me! it certainly shows that application of Cadulac underbody treatment

helped + I think the car has been dry stored for some of its life . I used to do a lot of body repair

work for a local BL dealer back in the day whom got the cars he sold done with a similar product

can't remember which! i was always cursing him , for it dripping on me when fitting new panels,

Anyway on with the story,

Got it all stripped as far as I can go at the moment! got to keep it mobile as need to move in and out of garage! got to keep

the Sprite inside at night for Insurance.

Some mostly surface rust on roof when the venal was removed! I think the coach builders could have used a better primmer

as the final must be a bit porous,

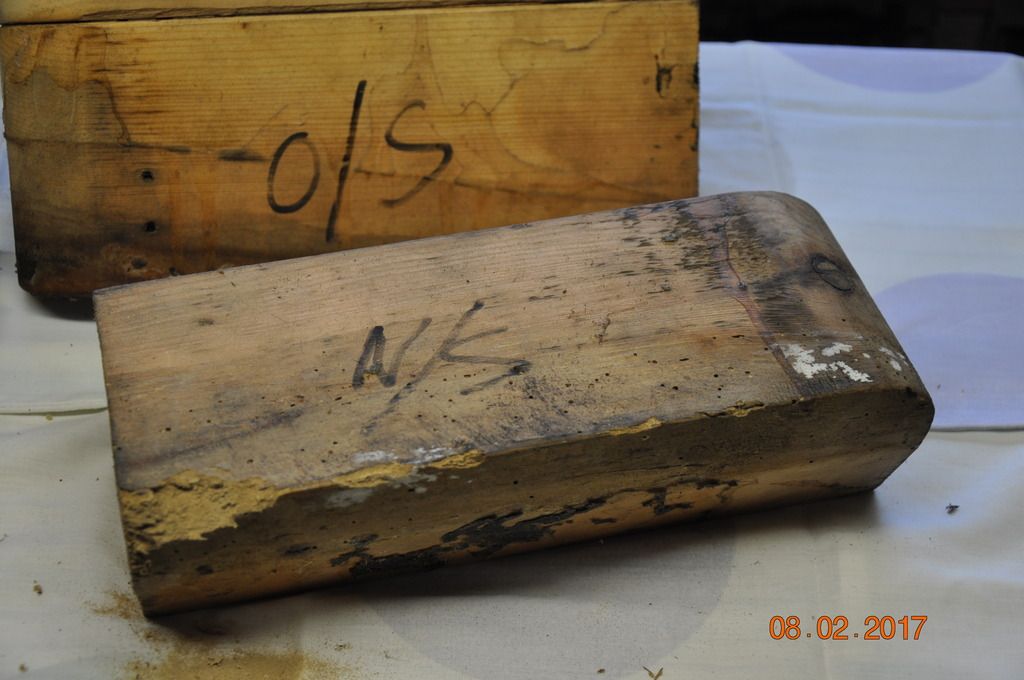

a shot of the position of the coach lines that were brush applied with gold leaf!! will need to find someone to redo when the

time comes ( never did master the technique despite having seen it done many times by an expert) HaHa,

solid looking round the air vents and inner A post,

just some surface rust on usual troublesome areas behind shocker mounts, What a pity BL fitted these over bare metal,

when over sill removed found no wax oil inside, most of the original sill was still intact, and most of inner sill not to bad,

lower flitch will need a repair ,

removed the original sill, need to clean up traces o spot welds, even after 50yrs in the trade still hate drilling out spot welds

when I don't need to,

this repair half A panel was held!!! on with 3 1/8th bits of bird poo weld, having said that it would have been a major job to

replace complete A panel.

that it up to date for today, thanks for looking.

Hi 'spraybeater' great to see you have started the restoration of this very rare surviving Oyler Coachbuilt Mini..........I will be following this thread with great interest. (Have also posted a link update on the Mk1 Forum).

http://mk1-forum.net...php?f=5&t=14209

Thanks for that ,mab01uk, and I must thank you for your original response on this ! as that was the reason I

purchased it, and although its taken a year before starting restoration I certainly don't regret purchasing.

Frank