Hi everybody.

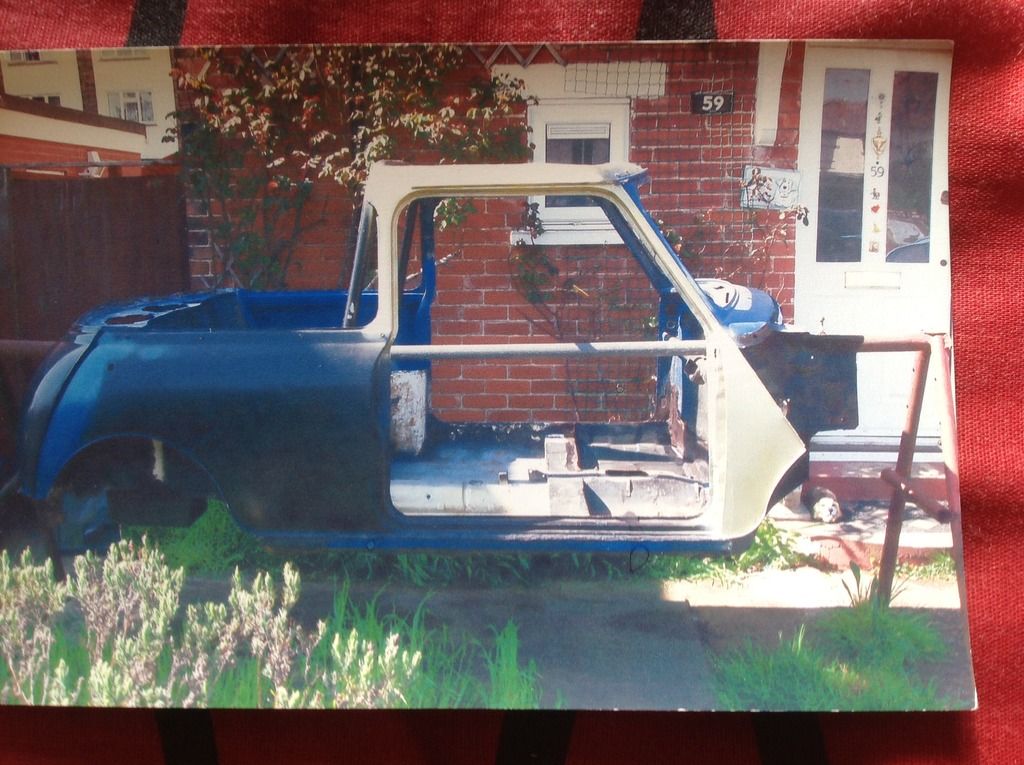

Meet caddy.

My very long term build of 10 years.

She was built 24/11/1977 and started life as a 1275 gt clubman in white.

I bought her may 2007 for £400.

Having spent 10 years in a warehouse covered up,she arrived at my place and after i stripped her shell she looked like this see pic below.

In 93 i had a clubman estate and when ever i was working on it i use to hit the back of my head on the bonnet catch many times, so this time round i decided to make the front removable but keep the original front end.

After a lot of grinding and dremmel work the front end was off but intact.

I then had an issue were i had no further monies to carry on and no dry place to store her,so she was covered up and spent the next 3 1/2 years outside the front of my house with polythene,shrinkwrap,tarpaulins and rope.

So now it was 04/2010 and i was now in a position to start work on her.she was uncovered and was still how i had left her in 2007

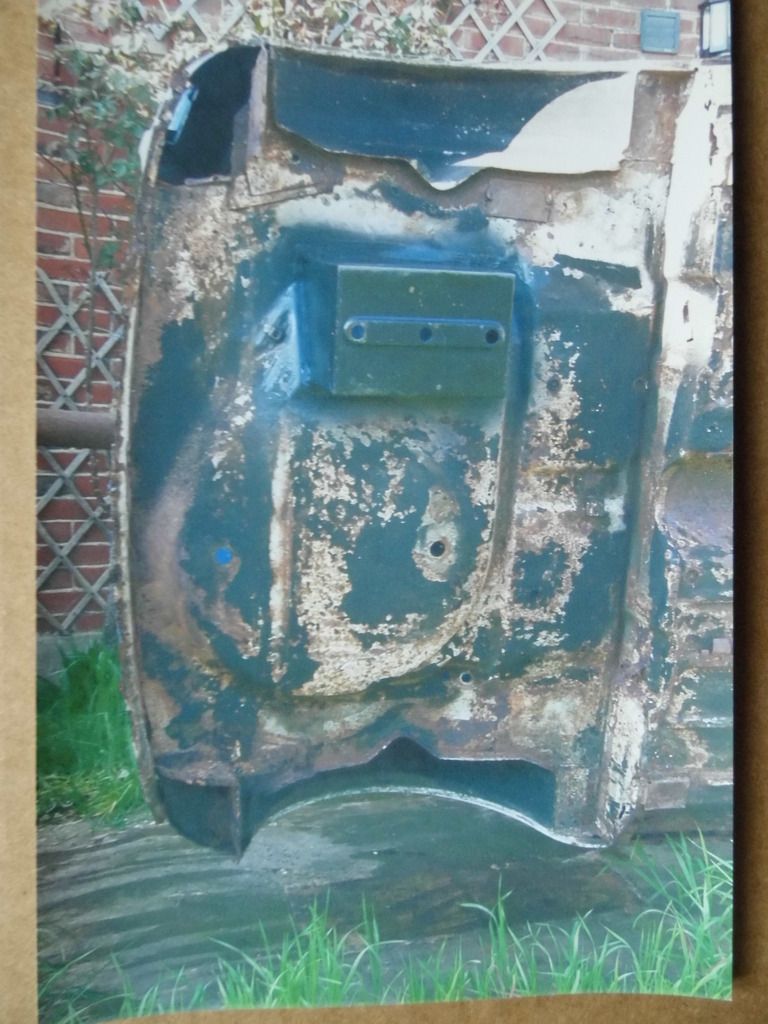

Firstly to see where all the rot was.

It needed front floor pans,A panels,inner and outer seals,both door skins,lower inner door panel,both outer rear quarter panels,heal board,rear valance,rear valance supports,last part of boot floor,complete boot panel,parcel shelf and inner and outer seals.

So i tackled the floor pans first,ordered new front floor pans and when they arrived,cut the passenger side out first.

Offered up the new floor pan and spotted in place, before i welded it all round.

To my horror i cant weld very well, i managed to weld all four edges but only one came out very well,the other three sides looked like bird poo and i kept blowing holes.

So i called it quits and decided to try and find someone who could tackle it instead.

After a very long time (now october 2010) i found a chap who would undertake the mammoth repairs to my shell.

We agreed on a monthly budget system and it was decided to have the shell shot blasted and red oxide coated to protect it before work commenced.

So i said goodbye to my project and off it went.

After about 6 weeks and £670 later she was at her new home to be repaired.

Now the chap doing the work had agreed with me to accept £400 per month and he would do £400 of work so it would progress slowly but still progress,well i was on a very tight budget.

Well 11 months on and £2850 the chap had only done about 3 months of work on her.

Then drops a bomb shell and tells me hes closing up and come and get your car.

So i had to hire a lutton to get her back, arrived at the storage unit put car onto tail lift and up she went.

Tied her down and took her away.

He had basically just replaced the rear outer quarter panels,full outer boot panel,parcel shelf,boot floor panel,front drivers floor pan and sorted out my dodgy welding on the passenger floor panel.

He had taken pics as he went but i have never received them.

So moving on after about 6 months i found a new chap that would carry on the work.

He agreed to some new terms on payment and basically sorted out a lot of issues.

Firstly the rear outer quarter panels had to come off and be redone as previous guy had messed up,parcel shelf wasnt spotted correctly so had to be redone.

Now new chap was a kitchen fitter by trade so did cars as a hobby at weekends.

He sorted out an issue with the roll bar at the back as the roof had split away from the roll bar on both sides.

In the meantime i took both doors from sussex to blackpool to have them reskinned and sorted.

Loaded up my polo and drove to blackpool, (dont trust couriers to deliver in good condition).

On the way to blackpool, wet day, we discovered our sunroof leaked and had to stop several times to stop the water leaks. When we next stopped it had stopped raining and so i sealed up the sunroof with gaffa tape.

Got to blackpool and dropped off the doors.

The doors were away for about 2 weeks and came back to me in remarkable condition.

The mini door company in blackpool had replaced the outer skins using a jig,installed new rivnuts for the mirrors,replaced the bottom of the inner part of the door,repaired the centre of the inner panel as this had been butchered by someone in the past trying to fit deadlocks.

The doors when he sent them back to me were packaged like the crown jewels.

More to follow.

Edited by Rapidmini59, 29 May 2017 - 08:16 PM.