I'm in the process of building up the hubs on a Cooper S disc conversion kit and i've spent the best part of today shimming the ball joints.

This is the first time i've ever fitted fitted/shimmed mini ball joints, so i'm not exactly sure how the ball joints should feel when correctly fitted and torqued up etc.

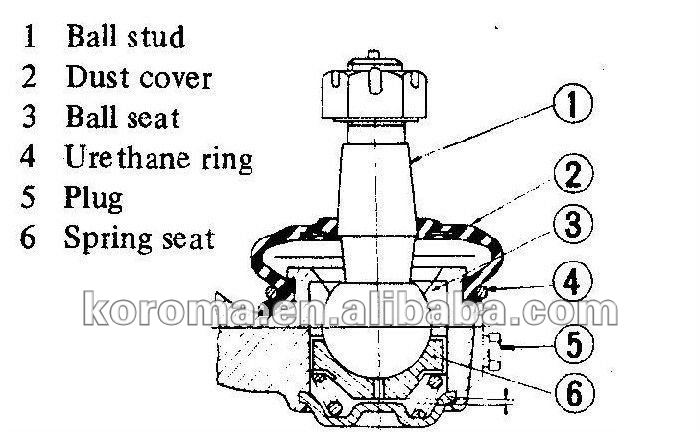

I'd done a fair bit of research beforehand and decided to not fit the ones supplied with the kit (didn't seem to be of good quality) and sourced a set of genuine Quinton Hazel ones. I've then lapped in all the joints with fine valve grinding paste for 5 mins per joint (this made them a lot smoother) and then thoroughly cleaned them and then begun the process of shimming them.

Now i've had a good search through the threads on this forum, other mini forums, google and my Haynes/Mini manuals there just seems to be conflicting answers as to how tight ball joints should be.

Haynes just says 'slight resistance should be felt', random Mini manual says '0.003" to no nip?'.

Lots of people say they should be so tight that they can only be moved by putting a ring spanner over the end of the pin, i've tried this but it just seems far to tight to me?

Some people say you should set them so you can 'just about' move them by hand but i've found setting them like this caused them to be tight in certain spots and loose on others.

However a couple of people say that they set them so that they have no up and down play/free float but can be easily moved by a finger.

I'm really not sure what advice to follow now as there seems to be no definite answer but as ball joints are a critical suspension part resulting in serious consequences if not properly installed, i want to get it right!

I have currently set them so they have no up or down play at all but move easily and smoothly with one finger in all directions and torqued them up to the correct setting. I have't bent up the lock tabs yet until i have a better idea as to how they should be.

Thanks in advance ![]()