If the cam sensor is too high I'm a tad concerned you might have worse clearance issues if it's going in a standard front subframe.

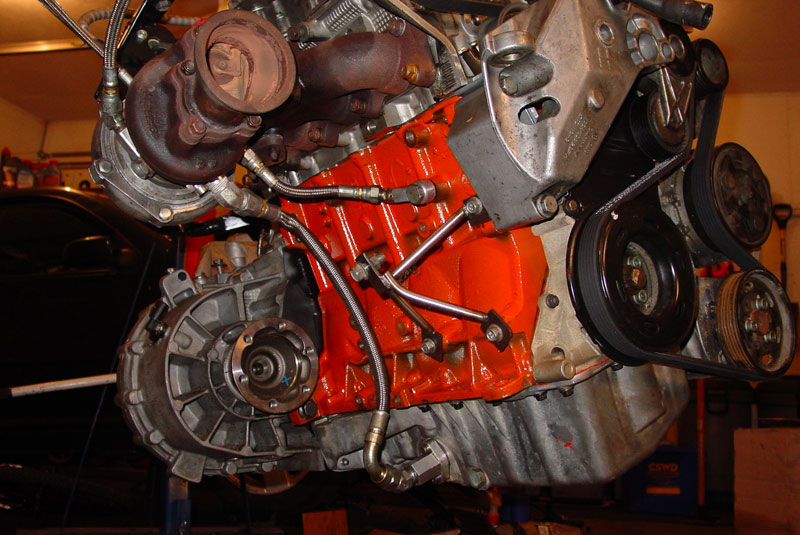

Clearance isn't an issue behind, the manifold and turbo are your regular set up on a lot of turbo mini's, however the MPi has the annoying issue of not having a fuel pump hole in the block. The cam sensor sits higher than this would normally and isn't an option as it's right behind the cold side of the turbo.

Why would i need a scavenger pump? Surely gravity will be doing the job after the oil escapes the turbo's core, like on every other petrol turbo engine.