Thanks again for the replies and ideas.

In answer to you Moke Spider;

- I see your point that changing the push rod will not change the length of travel - only the arc of movement.

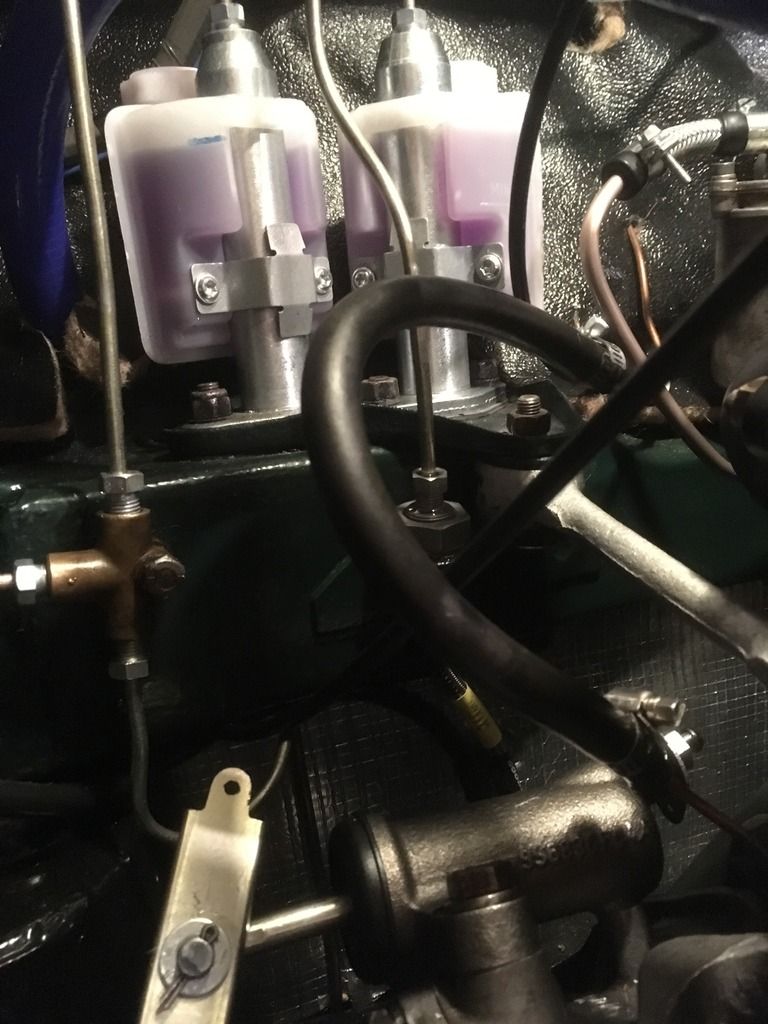

- I have the normal gasket under the master - its quite a thick card one - and everything is bolted down tight.

- The push rod was renewed when I renewed the slave cylinder - the push rod was the same length as the original - and the slave is the type without a circlip.

- The clevis pin is in good condition and a good fit in the clutch cover.

- I think the suggestion you make about the nut in the master cylinder will not change anything due to what we said above in (1).

- Setting the stop adjustment back 1 'flat' gives about 0.004' clearance but that didn't help.

Your other suggestion, about putting a washer between the thrust bearing and the shoulder of the plunger, I can see would change the position of the operating arm relative to the stop adjustment nut. Again though this would not change the travel of the push rod. Also, I would have to dismantle the clutch to do this and again to undo it if it didn't work. I wouldn't mind doing this if I knew it was the issue but if the hydraulics don't seem to be working as they should my gut feeling is sort that out first. I hear what you say about silicone fluids. As I've said I was careful and in terms of time for micro bubbles to settle - leaving it a couple of weeks at times.

It seems to me that my next steps should be to;

- swap the master and/or slave cylinder (even though they are new) and see if doing that gives better travel

Or

- Change to DOT 5.1 hydraulic fluid

Unless there are any other suggestions which one first do you think? And any tips on cleaning the old DOT5.0 out of the system before putting the 5.1 in?

Thanks agin for your help everyone.

Tim

Tim,

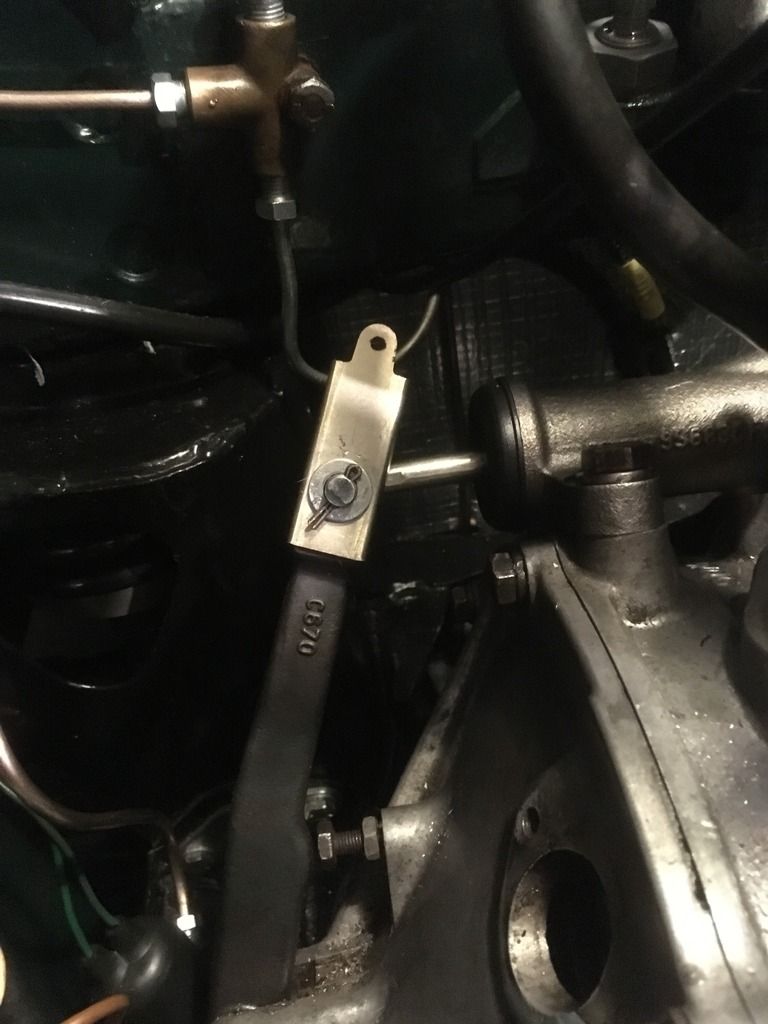

Thanks for your comprehensive reply and I agree, changing anything at the Arm or Push Rod won't help, however, there is one item to check here and that is the Angle that the Arm sits at at rest. You probably need to post up a photo for us on that. If the Angle of Arc that the little Ball on the Arm moves through is not 'through' 90 degrees to the plunger, then the Plunger itself will have reduced movement, but given the short travel at the Slave, I don't feel this is the issue here.

Given the Slave doesn't have a Circlip, then the issue I feel is 'upstream' from the Slave.

If you look in the back of the Pedal Box, where the Clevis Pins are for the Master Cylinders, with your foot off the pedal you should only have no more than about 4 mm here from the under side of the Pedal, to the bottom of the 'Box'. If you have more than that, then for some reason, the Master is not 'sitting' low enough to get a full stroke. It could be a short Push Rod in the Master for some odd reason, a bent Pedal Box a bent Pedal, worn Clevis hole in the Pedal.

I find that with 5/8" stroke at the Slave, the clutch take up is at about 1/2 pedal travel, ie, well off the floor, when they get down about that 1/2" mark,they start taking up just off the floor as you are seeing.

Also, regarding fluid, if you are changing away from the Silicon Fluid, I wouldn't recommend going to DOT 5.1 for a road car. The higher the boiling point of Glycol based fluids, the more hydroscopic it is and it will absorb moisture fast. I ran it in the Race Car and was advised to change it out immediately after every meeting and again before every run. I felt that was excessive but learnt the hard way soon after using this fluid. For road use, a DOT 3 would be sensible.