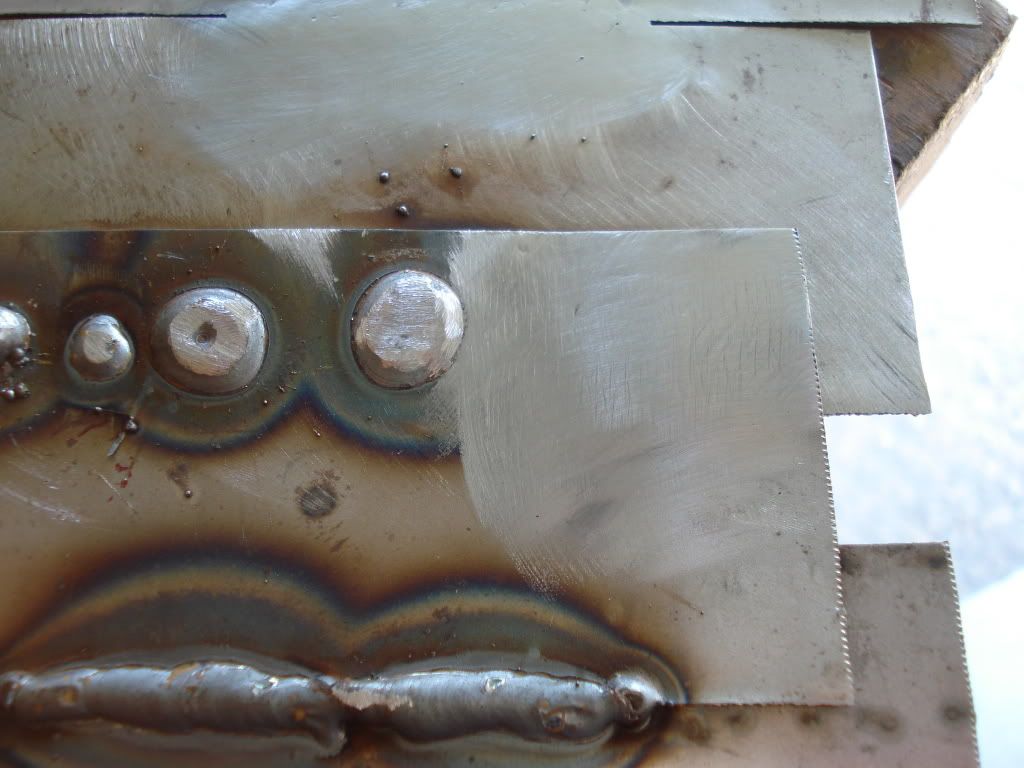

I prepped both surfaces front and back and exposed bare metal. Plug welding with good penetration and ground back. As you can see from the images, 70% have filled and ground back nicely, the other 30% have either blown holes or not filled very well. I practised on loads of metal prior to this, most of similar thickness with good results - hence moving onto the panels.

I am using a Clarke 135te with argon mix gas. Settings on 2 and MIN, wire speed 6/7. I did then try 1 and Max, same wire speed. Both times gas flow has been set to 6ish (using the hobby bottles - I know they aren’t the best and run out, will soon convert to larger bottles)

Can anyone advise where I’m going wrong please or any tips on filling the remaining holes.

Again, your help is greatly appreciated.