Remove all carpets from under the clutch pedal and ensure that it goes fully to the floor or just short of if the throw out stops engage with the wok. Bleed the the slave, nipping up the bleed nipple with the pedal depressed.

On the basis that you have changed the clutch master and slave cylinders then it should be safe to assume that they are giving the correct travel at the slave. I stand to be corrected but check that the linear travel at the slave rod is 0.5"

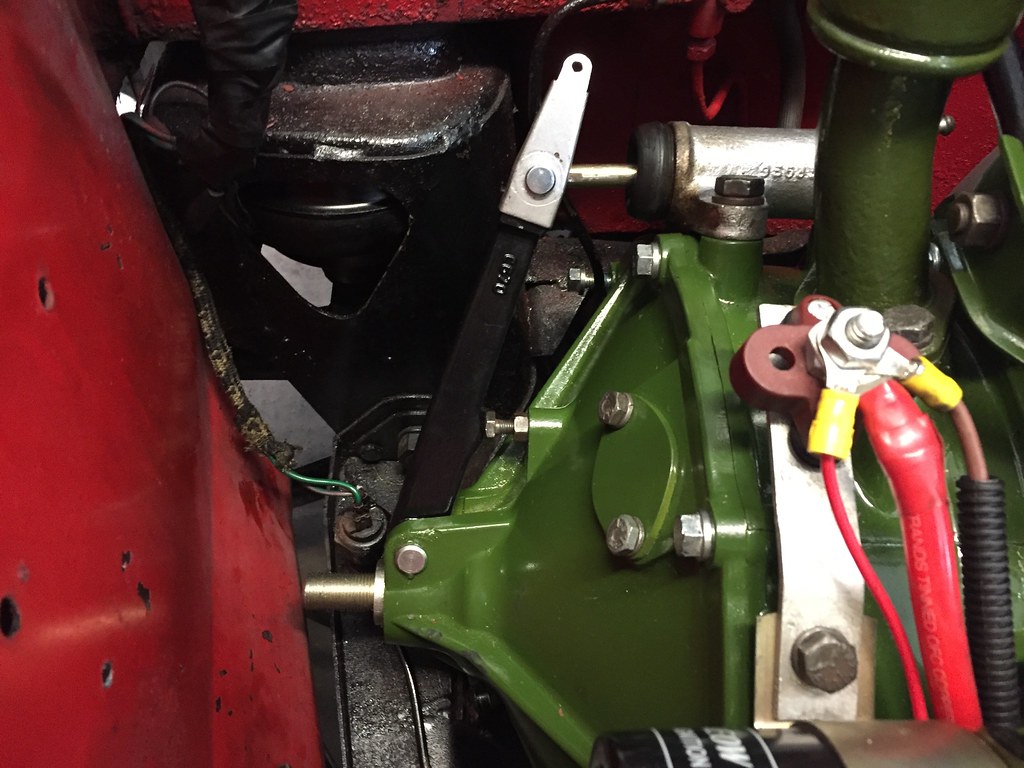

When you check this travel, do it with the slave cylinder boot off so that you can see the slave piston pushing the rod. It is essential the slave piston does not hit against the circlip otherwise travel will be limited.If it is anywhere near the circlip on clutch pedal fully down then you do need to extend the pushrod. I did this only recently when I fitted a new (race) clutch plate which was slightly thicker than the previous design. Whatever you extend the rod with you must ensure that it will go through the circlip on the slave cylinder without any interfearance, otherwise travel is limited. From memory my extension to the pushrod is approx +5mm.

Minimise the clutch clearance adjustment to 10thou and the throw out stop to butting up to the wok at full pedal depression then one flat further in.

Best of luck. You are right, it can do your head in !

Edited by rww, 20 August 2019 - 05:49 PM.