Right then.,,, the saga continues.

I took the ECU to ATP for a check and they confirmed the suspected lambda heater problem and another problem with the fuel pump circuit but said they couldn’t find anything that would cause the idle symptoms I am getting. I had them rebuild it anyway to eliminate variables and I’ve put it back on the car but the problem still persists.

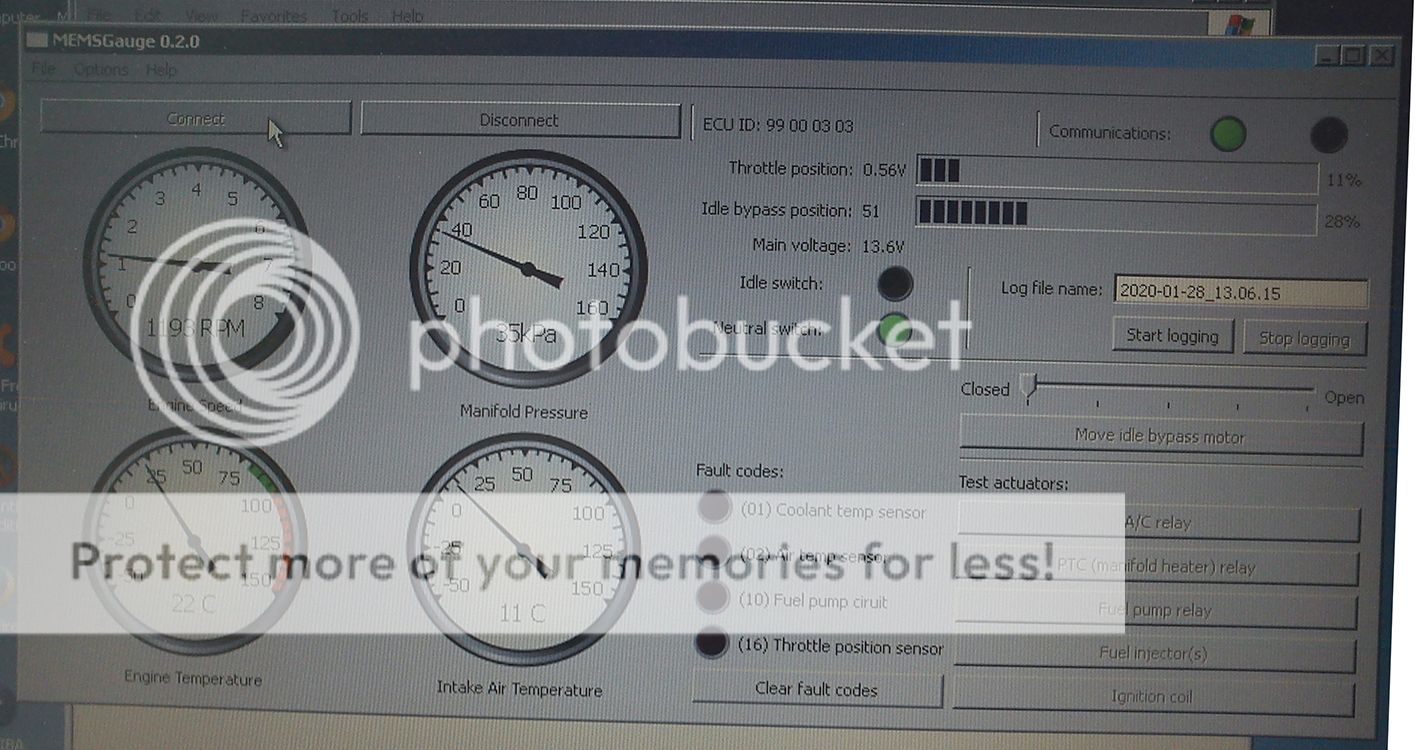

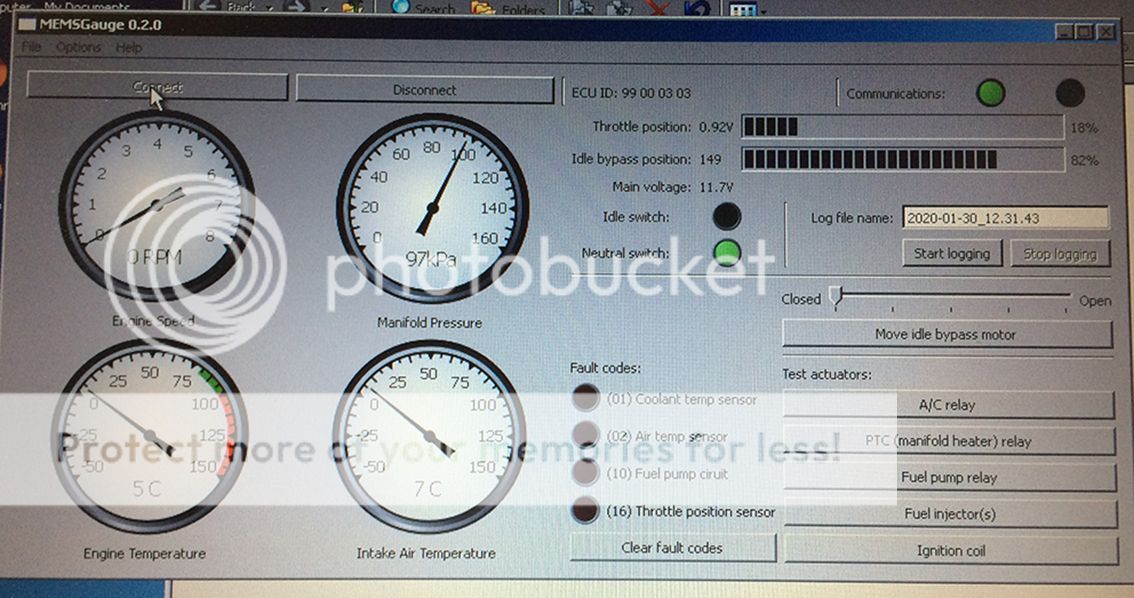

I have got hold of MEMS Gauge, MEMS Scan and MEMS Analyser and checked for faults. Initially, after refitting the ECU there were 3 error codes stored (coolant temp, air temp and fuel pump circuit). These I cleared with MEMS Gauge and they have not come back after a few runs.

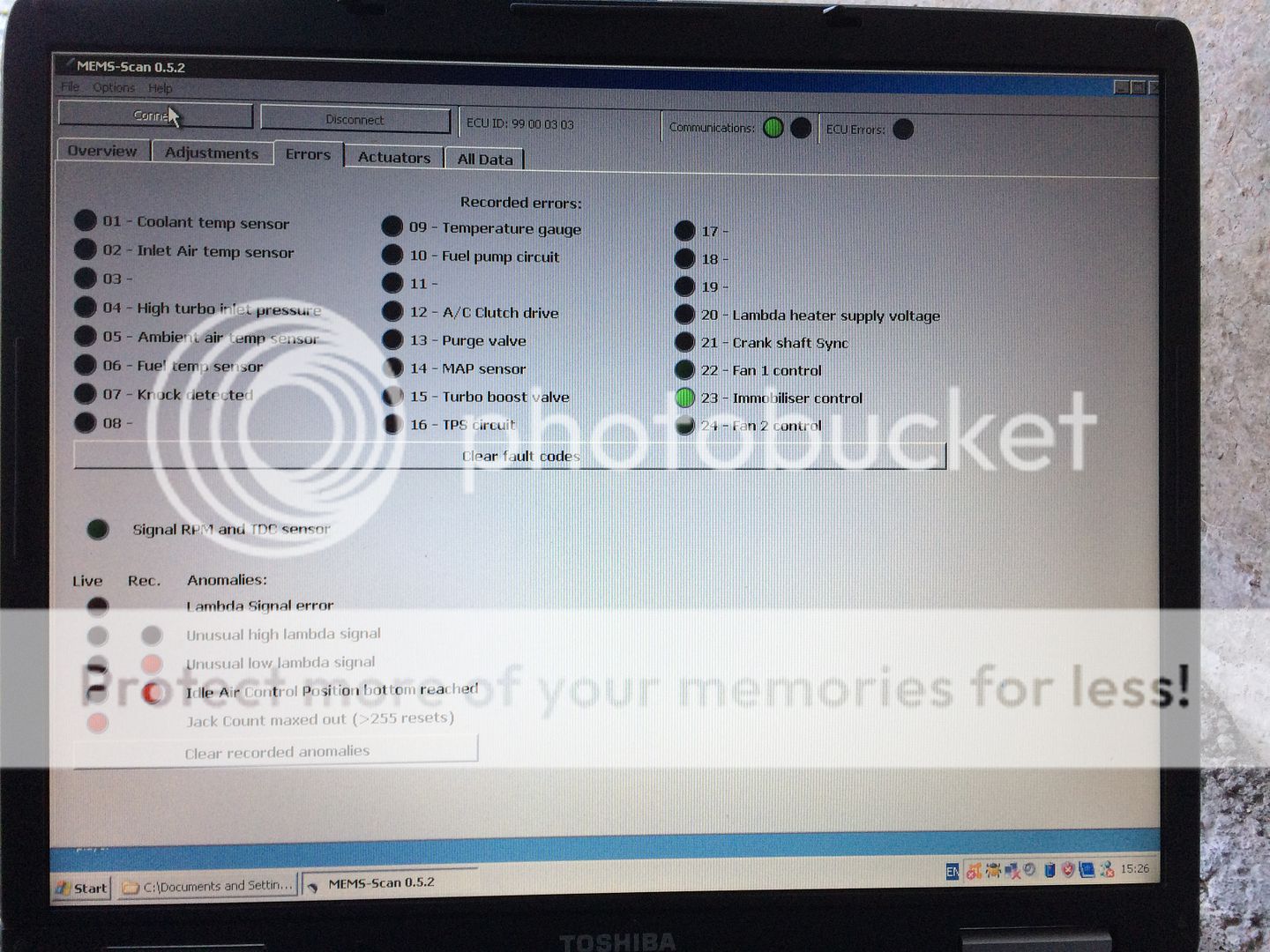

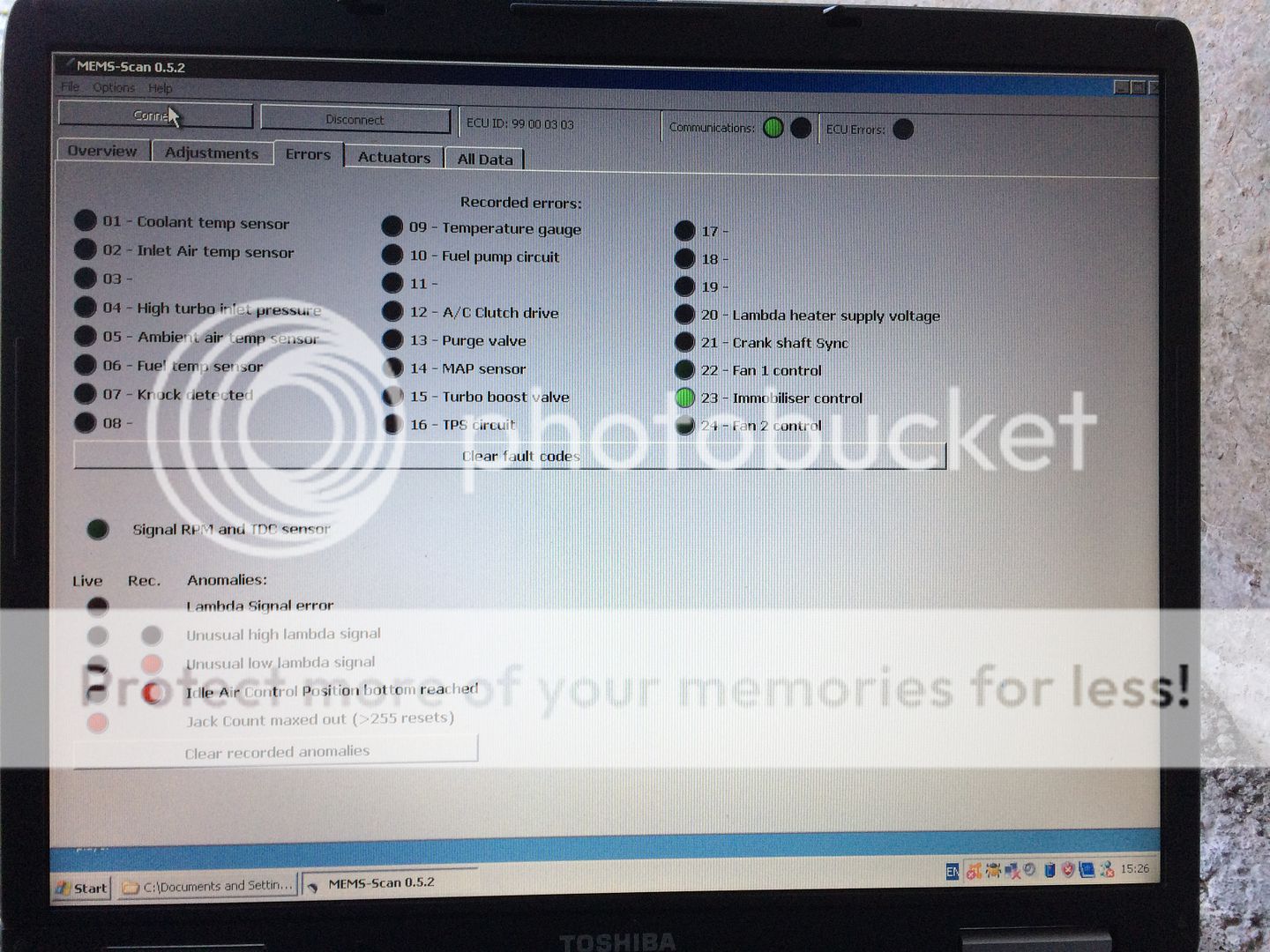

I tried MEMs Scan as it gives a bit more information and all the error codes were clear. The only anomaly it recorded was an ‘Unusually Low Lambda Signal’ pic -

This anomaly disappears after re-starting the program.

The live data saw the Lambda voltage swinging between about 80 to 890 mV

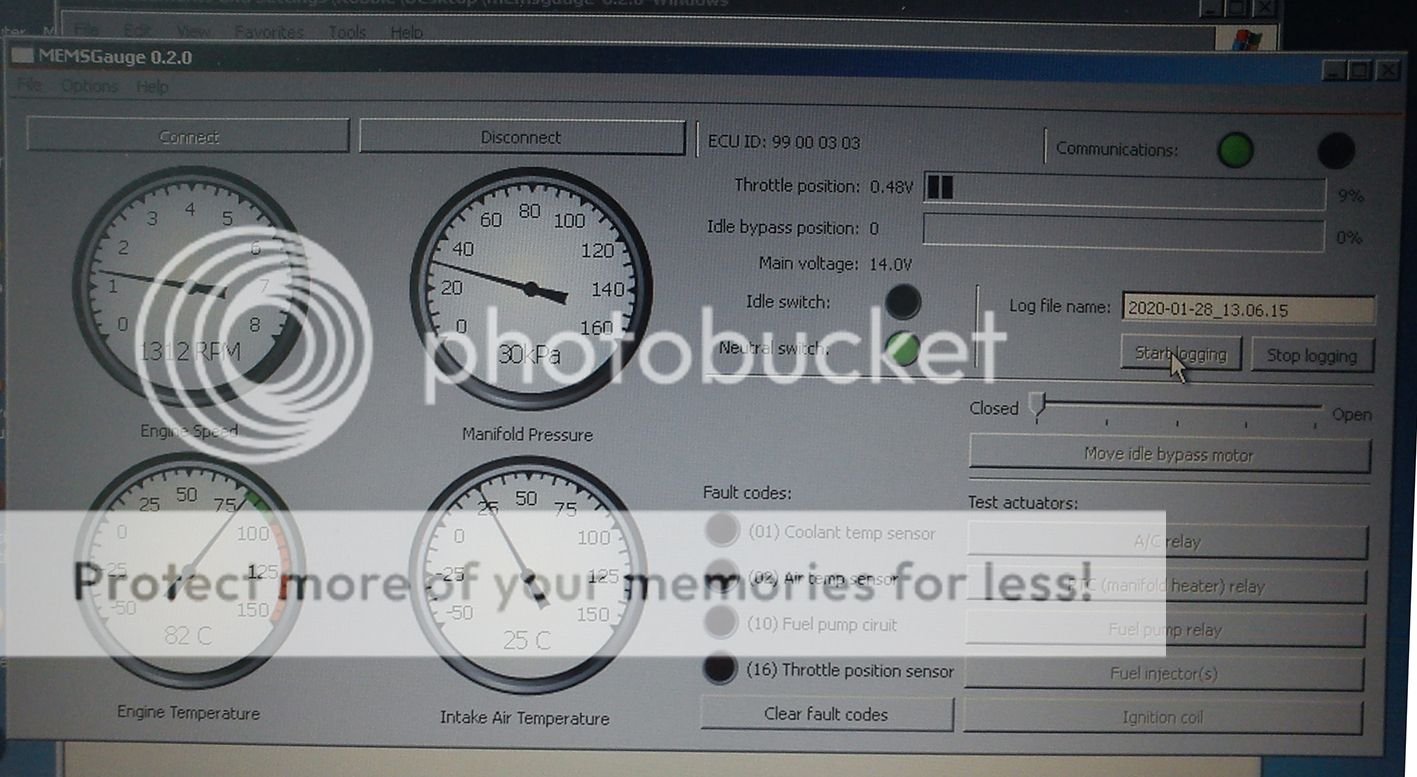

Other values were, with engine idling about 1400rpm,

manifold pressure around 30kPa.

coolant temp about 84 deg c,

throttle pos 12%,

idle air motor position 0%

I recorded a couple of log files, the one from MEMS Scan isn’t recognised by MEMS Analyser and the ones from MEMS Gauge look corrupted to me - the information is a clear graph like the example files. At first I thought it was because the pc ran out of battery during the recording but the next on was the same. I have attached them anyway incase someone can make sense of them - perhaps I am doing something wrong.

So I am mystified as the cause of the problem, surely anything wrong would show up as a fault on the diagnostic information?