Did you have this recondtioned or did you buy it reconditioned? Lucky he has agreed to ship the parts, fingers crossed.

1275 Gt - Metro Turbo 1310 Engine Project

#46

Posted 24 May 2020 - 01:49 PM

#47

Posted 24 May 2020 - 01:59 PM

Did you have this recondtioned or did you buy it reconditioned? Lucky he has agreed to ship the parts, fingers crossed.

I paid good money to have it done. not cheap job. professional engine builder that supposedly builds race engines. Mini specialist. Member on TMF. I am disappointed. The whole point of me paying for the work was to get the best job. I am not an engine builder. This is my first build. That does not mean im an idiot though. I may not build engines but am an engineer with many years of knowledge. I just hope the parts get shipped or I will have no choice but to buy again what ive already paid for.

I may be asking a few questions this week .... I think i will invest in 2 creates of Stella now to keep me focused :)

#48

Posted 25 May 2020 - 09:01 AM

#49

Posted 25 May 2020 - 02:57 PM

From many other threads, you’ve been lucky to get hold of him.

I think the business may have been closed down now.

#50

Posted 25 May 2020 - 05:11 PM

From many other threads, you’ve been lucky to get hold of him.

I think the business may have been closed down now.

#51

Posted 25 May 2020 - 05:12 PM

#52

Posted 26 May 2020 - 09:09 PM

Shocking for an engine builder to be like that.

Agreed. Was hoping to finish the engine this week. But now maybe a few more weeks. Read some of your build looks really nice. I really didnt need any more delays on mine

#53

Posted 31 May 2020 - 04:12 PM

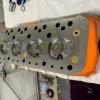

Cylinder head

So the build continues. With a large amount of asking questions... I have stripped complete cylinder head and checked valve seats. Not lapped in so thats been the task this weekend along with painting the head. Valves all ready to go back in when the paint drys then check volume of head for CR calculations.

IMG_1363.JPG 46.85K

1 downloads

IMG_1363.JPG 46.85K

1 downloads

IMG_1371.JPG 51.15K

1 downloads

IMG_1371.JPG 51.15K

1 downloads

#54

Posted 03 June 2020 - 05:34 AM

Excellent work on your rebuild so far. That gearbox and flywheel housing cover looks virtually brand new.

#55

Posted 03 June 2020 - 05:53 AM

Excellent work on your rebuild so far. That gearbox and flywheel housing cover looks virtually brand new.

Thanks. The gearbox and transfer case were just glass blast in my garage. Cheap £80 shot blast unit and some fine glass media. makes a right mess but did a lovely job of the casings. Didnt paint after as paint will chip being so close to the road. Hope it last a long time. Sprayed with ACF 50 to prevent corrosion and staining. The clutch cover was just polishing wheel in a battery drill for probably 4 hours. I could have polished more but its only a clutch cover.

#56

Posted 03 June 2020 - 08:22 AM

Compression ratio calculations

I have posted on the forum for some assistance in being most accurate with my CR checks. But as this is my project thread i thought i would copy the info in here. Keeps a good record of my project then.

____________________________________________________________________________________________________________________________________________________

So ive finally managed to get busy and calculate [best possible] my CR. My concern is so many varied options of numbers i can and have used. I ordered a burette for measuring. I must add a picture at some point as this thing is so big it could never be used... Resorted to syringe used for MTB brakes. Pretty accurate and its all i had. 0-35 ml in 1ml increments. Perspex plate with 2 small holes drilled. 1 to fill through - 1 to let air escape easier. Grease to seal surface. No alcohol or food die. Used my black current an apple juice that was on the side [I truly am an armature].

So the results -

Head chamber volume - 21cc [checked 3 times and exact every time @ 21cc]

Head gasket - 3.3cc [info taken from MS site for a BK450 compressed gasket]

Deck clearance - 0.93mm = 3.7cc [measured with a vernier caliper. this could be more accurate]

Piston crown dish - 9.38cc [taken from MS site advised for Mega piston]

Ring land volume - 0.6cc [this info was taken from various other threads and can not be classed as accurate. but is needed i think]

Total = 37.98cc

Displacement - 327.5cc [this is the standard number used I believe for a 1310 engine]

This gives me a calculated CR of - 9.6/1

But im still a little confused. I measured the removed BK450 gasket and although not highly accurate calculated its volume at 3.79cc then on the forum found most people are using 4cc for this gasket. I then also used fluid to check the volume in the piston to deck area and got a value of 14cc across 3 measurements. Also calculated displacement from what i measured and stroke @ 81.28mm. Displacement worked out at 327.26cc

so i do the maths again -

Head chamber volume - 21cc

Head gasket - 3.79cc

Deck clearance - Piston crown dish - Ring land volume - [now measured using fluid in chamber and syringe] 14cc

Total = 38.79cc

Displacement - 327.26cc

This gives me a calculated CR of - 9.42/1

There is also a reference to the BK450 gasket being calculated at 4cc so if i use this number -

This gives me a calculated CR of - 9.39/1

Im hoping by now you see what my problem is... What is the best numbers to use? Mini spares advise no more than 9.4/1 CR to be used.. Im seeing numbers that show between 9.3 and 9.6 dependant on how i do the maths.

Any feed back welcome - This is intended to run on a turbo engine with only standard setup.

#57

Posted 03 June 2020 - 08:29 AM

https://youtu.be/qHoOWEu7IlA

https://youtu.be/lZCIW2TuOQY

Edited by imack, 03 June 2020 - 08:31 AM.

#58

Posted 03 June 2020 - 08:54 AM

Just watched the first part about head gasket and that almost matches what I have added. But would give me an even lower CR. I posted this in problems and questions and have been sent a link for a calculator and that used 3.4 as the standard for head gasket. I measure nearly 3.8 - Other references are found at 4 and now MED say 4.2

My heads going to pop.... Just this gasket thickness is enough to change my ratio from 9.3 to 9.6

#59

Posted 03 June 2020 - 02:54 PM

Info all collected and numbers done with. The final CR is calculated at the standard 9.4/1 as it should originally be for the engine. I have ordered all additional parts to complete the engine build - ARP bolt set - Piston insertion tool - New conrod bolts - i must say the service from MED today was excellent and parts will arrive tomorrow.

Then i thought i would take a quick look at the primary gear. What a surprise there is almost 1mm of play on the shaft. So quick chat with Guess works and hopefully will manage to have a reconditioned primary gear for the weekend. That should complete the list of bits i hope. Again a pleasure to deal with Guess works. Excellent service.

The build will start Saturday providing i dont find any more surprises or some extra bits i have overlooked.... Not extracted pistons yet. Just hope the rings are OK and not been hammered in.

Final note: Not received any parts or communication from Retro Minis regarding the shocking work done. There phone no longer rings. The emails never get replied to. I have sent a request for financial compensation regarding all work. If the email is not responded to in the next 7 days i will start the court proceedings.

#60

Posted 03 June 2020 - 06:26 PM

Engine rebuild

This seems like the never ending job to get the engine built. I have stripped and painted the block. Fitted 2 new core plugs and got 3 more to do. They are removed just need to knock them in. The engine was stripped / inspected / rebuilt to check CR. Now stripped again as i was waiting for some new parts to arrive. Here are some pictures of some of the stuff been going on -

IMG_1356.JPG 42.1K

0 downloads

IMG_1356.JPG 42.1K

0 downloads

IMG_1371.JPG 51.15K

1 downloads

IMG_1371.JPG 51.15K

1 downloads

IMG_1381.JPG 46.64K

0 downloads

IMG_1381.JPG 46.64K

0 downloads

IMG_1383.JPG 41.82K

2 downloads

IMG_1383.JPG 41.82K

2 downloads

IMG_1380.JPG 65.46K

0 downloads

IMG_1380.JPG 65.46K

0 downloads

I could not stop myself adding a few bits to see what it will look like when complete :)

IMG_1390.JPG 33.45K

0 downloads

IMG_1390.JPG 33.45K

0 downloads

IMG_1398.JPG 37.3K

1 downloads

IMG_1398.JPG 37.3K

1 downloads

I did manage to get rid of all bubbles before checking cc

IMG_1401.JPG 32.47K

1 downloads

IMG_1401.JPG 32.47K

1 downloads

At least the pistons seem to be OK. Rings look new. Little reading to do now then full rebuild.

MY FIRST EVER ENGINE BUILD ...

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users