Hi guys, thought I would stick a build thread up.

I fancied a Mini again, and as it would fit easily in the garage it made sense!

So I found this sports le in jan 2018, I knew looking at it that it needed a fair amount of work but was hoping that I could do the minimum to get it on the road and use it for a year then strip it for rebuild. Well this didnt go to plan!

First a bit of history on the car as it has some background, registered in 98 but exported to a Rover Dealer in the Netherlands, it then seems to have come back to Rover in the UK and was used by Custom Consoles as their show car while it was still owned by the dealer. It was then purchased by a Gentleman in Surrey from Rover, he mainly took it to Wood & Pickett over a number of years I believe it was one of 3 Le's they looked after. They fitted the roof, did work on the interior and rebuilt the engine, there are receipts for thousands and normally a letter most years from WP for the cars valuation.

Anyway enough typing I will add some photos in. I sent it straight for an MOT, I think it was 4 major fails and about 13 advisories so I set to work. So in 2018 it had -

-Rocker gasket, new selector seal, bush gator and roll pin.

-New cv's both ends and a coat of paint, gearbox oil seals and flange gaskets.

-Front wheel bearings, front ball joints, track rod ends. Tie rod bushes and bolts.

-Brembo disks, pads, caliper rebuild, braided lines on the front end.

-Oil & filter change.

-I found some holes in the floor that were somehow missed on the mot so patched those for now.

-Rebuilt the rear brakes and new cables.

-New water pump, stat, belt, alloy rad, alloy header tank.

-New alternator, and ignition leads (The old one was fine, but I had it on my bench and managed to drop it on the floor!!).

-New heater matrix.

-Stripped the inlet manifold down, cleaned all sensors and fitted new injectors.

It then went for Mot but failed on emissions.

Some photos

IMG_20180106_110229 by Sken21, on Flickr

IMG_20180106_110229 by Sken21, on Flickr

IMG_20180523_195409 by Sken21, on Flickr

IMG_20180523_195409 by Sken21, on Flickr

IMG_20180523_195427 by Sken21, on Flickr

IMG_20180523_195427 by Sken21, on Flickr

IMG_20180615_225639 by Sken21, on Flickr

IMG_20180615_225639 by Sken21, on Flickr

IMG_20180619_203611 by Sken21, on Flickr

IMG_20180619_203611 by Sken21, on Flickr

IMG_20180928_171229 by Sken21, on Flickr

IMG_20180928_171229 by Sken21, on Flickr

IMG_20190418_183349 by Sken21, on Flickr

IMG_20190418_183349 by Sken21, on Flickr

So after failing on emissions, I basically threw money at it hoping to fix the problem!

I found that the wiring to the lambda probe was mainly broken, so I sourced a new plug, then the probe didnt seem to work, so I changed this for a new one. Still no difference, so I took it to a local garage to see if they could find anything, they said the probe was working but that the ECU seemed suspect. So I sent the ECU off for testing, which came back all ok. After this I did a compression test (Which I probably should have done in the first place), I found one cylinder to be down on pressure, and a wet test made no difference.

So I pulled the cylinder head (it has a large valve head supplied by OAP racing?), rebuilt the head, new stem seals and double valve springs and it was good to go. Now it was mid 2019 and the rust had set in, so on retest it failed on door steps, and a rear wheel cylinder had also seized up.

IMG_20190531_165931 by Sken21, on Flickr

IMG_20190531_165931 by Sken21, on Flickr

IMG_20190614_113709 by Sken21, on Flickr

IMG_20190614_113709 by Sken21, on Flickr

So since the lockdown I decided to strip the rear end. The rear valance was quite rusty in places.

When stripping I found that at some point someone stuck quite a lot of filler on the boot lip to rear valance, so it looked ok but was actually rotting under the filler. Not the best photo but its 2-3mm thick in places!

IMG_20200430_151712 by Sken21, on Flickr

IMG_20200430_151712 by Sken21, on Flickr

The left side is quite good inside, no rust at all, but the right side has some surface rust inside the boot, ive not decided whether to use these magnum panels or order a full heritage panel yet?? I also have some rust bubbling by the lower rear window.

IMG_20200430_164126 by Sken21, on Flickr

IMG_20200430_164126 by Sken21, on Flickr

Luckily underneath doesn't look terrible.

IMG_20200430_175037 by Sken21, on Flickr

IMG_20200430_175037 by Sken21, on Flickr

IMG_20200506_153704 by Sken21, on Flickr

IMG_20200506_153704 by Sken21, on Flickr

IMG_20200506_154042 by Sken21, on Flickr

IMG_20200506_154042 by Sken21, on Flickr

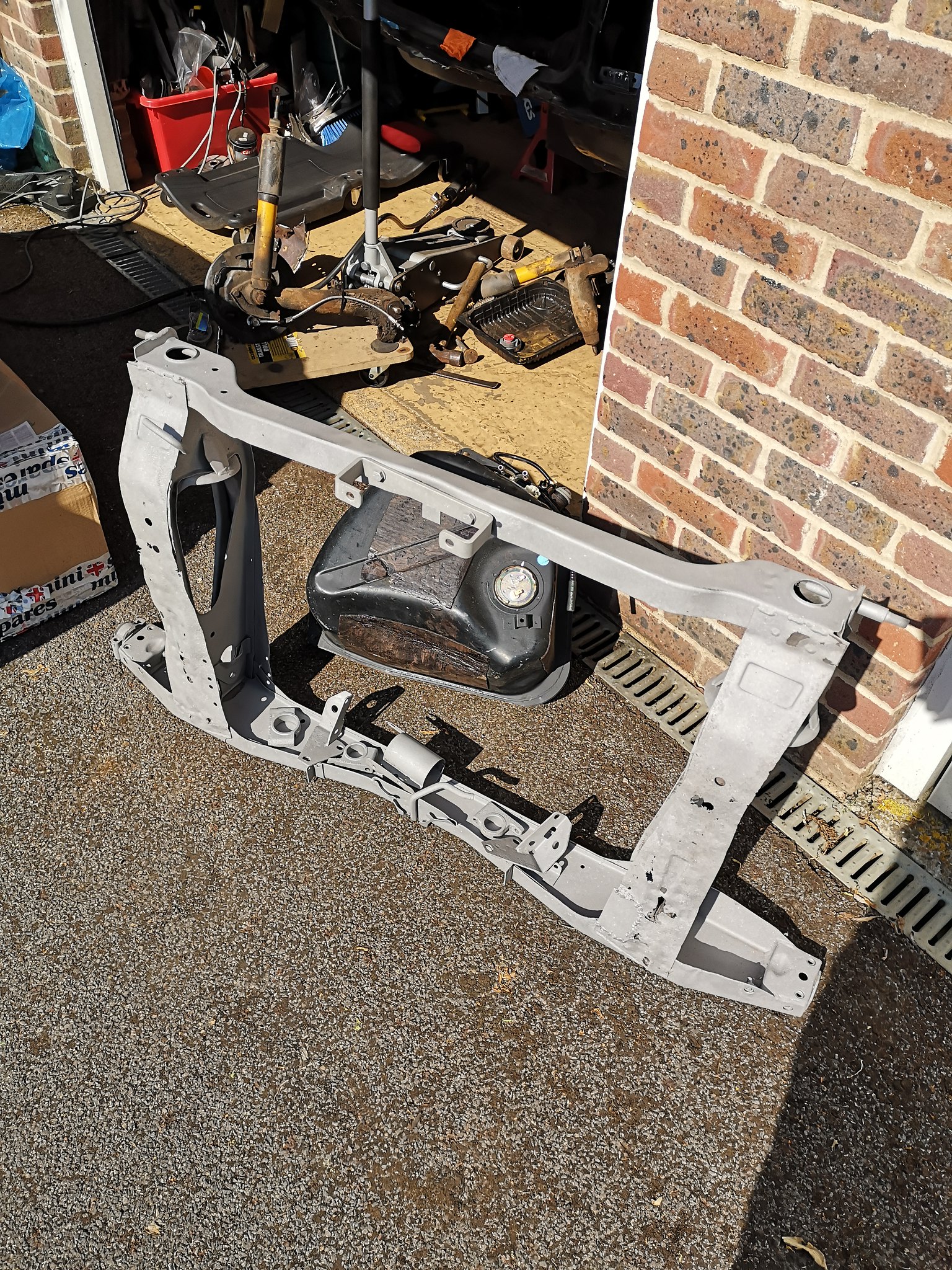

So I was under the impression mini spares were not doing the sportspack rear subframes yet, but I checked last nite and they are! so that probably would have been a better option but ive already started on mine.

I half expected it to fall apart on removal but it was ok, a guy down the road does metal finishing so he blasted it for me.

IMG_20200501_113913 by Sken21, on Flickr

IMG_20200501_113913 by Sken21, on Flickr

IMG_20200506_161614 by Sken21, on Flickr

IMG_20200506_161614 by Sken21, on Flickr

Ive now got repair panels for the lower arms, will spot weld and mig as required. Im using a upol weld through zinc primer, then epoxy primer, then it will be Raptor coated, will be doing similar on the underside and using some bilt hamber products.

Currently boot floor repair panel for the outer edge, maybe 0.5" has some surface corrosion towards the boot hinge.

Rear arches had gone in the top, new rear valance and closing panels (They were solid but a lot of rust).

IMG_20200430_143250 by Sken21, on Flickr

IMG_20200430_143250 by Sken21, on Flickr

Just started on a rear arch, which I wanted to do with the inner and quarter in place as they have no rust.

IMG_20200505_171535 by Sken21, on Flickr

IMG_20200505_171535 by Sken21, on Flickr

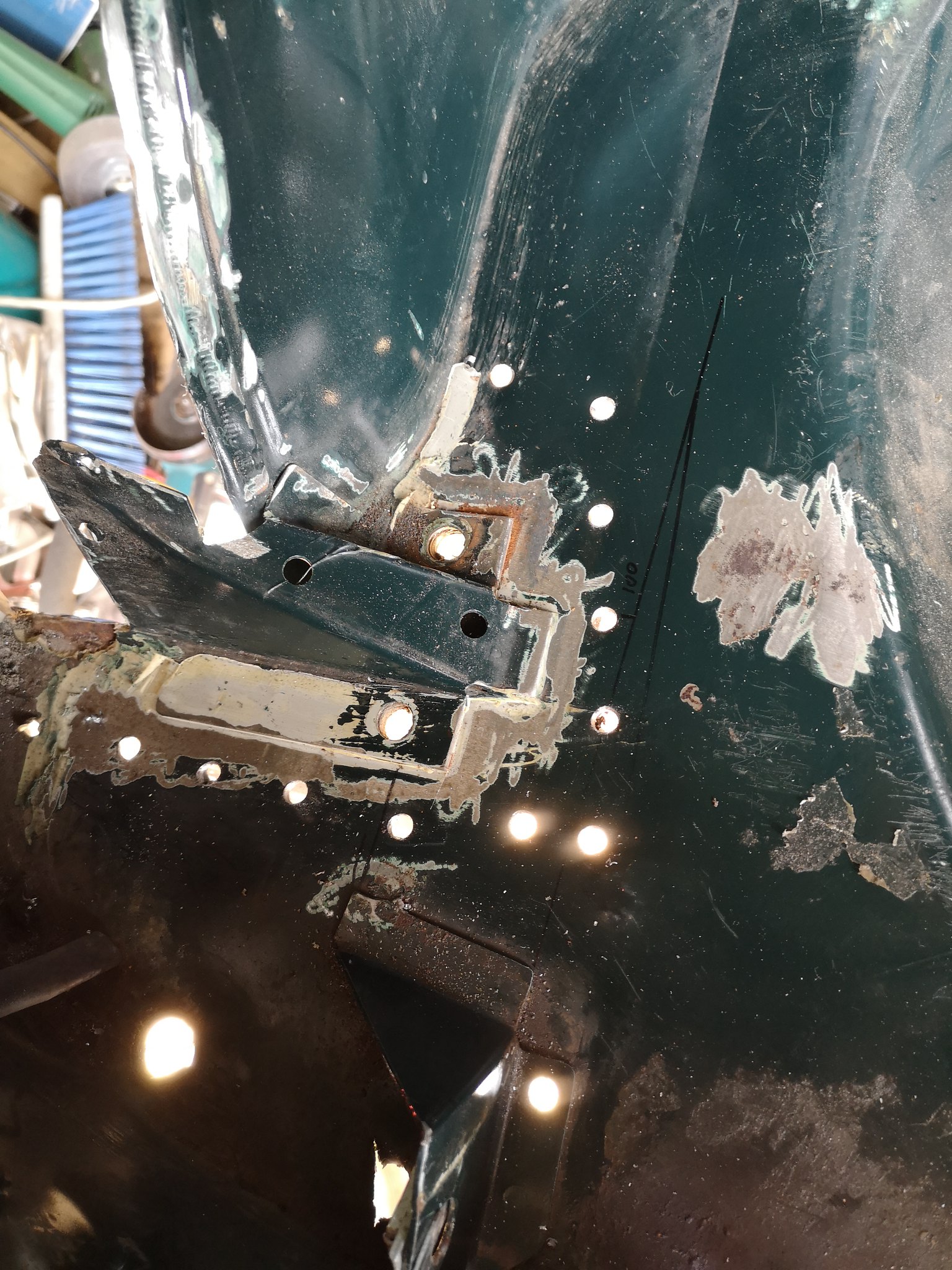

This had made it slightly trickier as I have the old lip in the boot.

IMG_20200505_171549 by Sken21, on Flickr

IMG_20200505_171549 by Sken21, on Flickr

Currently planning to cut the new lip off the heritage panel, then ill seam weld to the old lip from within the arch. Not sure if anyone has any better suggestions? trying to do it as well as possible!

Thanks for reading! :)