Right I've been off the forum for a while what with us moving house last year and various other things going on, story goes the other shell i just was not happy under taking the vast amount of work it required so i set about searching for another shell that's in 'better' condition to restore ( I put better like that as turns out it needs roughly the same but not as bad if that's even a thing ![]() )

)

Same as the last one this is for my partner as shes always wanted one, I'm sort of thinking that i will be hanging on to the other shell and the confidence I get with this one will spur me on to do that one for myself. May or may not happen but a nice idea never the less.

The topic title is pretty apt at the moment as shes not 100% sure how she wants it things like removable front end, interior, what engine will it have etc. So as it says project is undecided ![]()

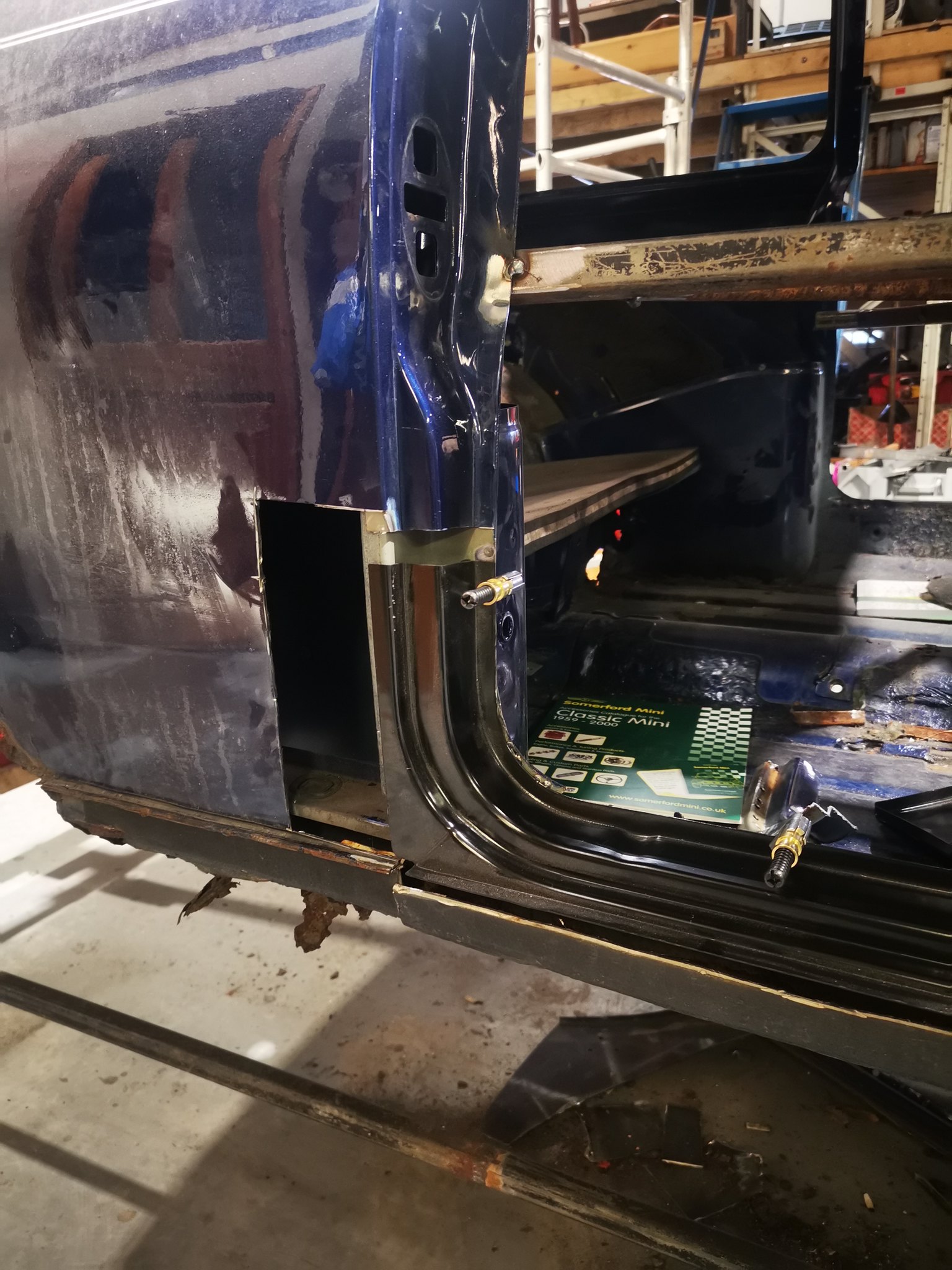

Right ill get some pictures up to show what I've got to contend with.

Pictures of the mini just after we collected it a couple of weeks ago.

I was pretty excited to get this into my workplace as the boss has allowed me to have it up here which is great as i can really put in a few hours after work a few nights a week and get good headway on it while were quieter than usual because of the current climate. So when works quiet in the afternoon I'm getting paid to work on this so winner winner ![]()

Edited by Thelowrider, 15 May 2020 - 06:50 PM.