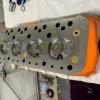

They are the old ones, but condition-wise they should be fine.

As i am no expert is there a correct clearance for cam to bearing?

The annoying part is i paid to have a lot of work done and when i have started to complete the build im finding many parts that are not as they should be -

Timing chain should have been IWIS - checked and its ROLON and does not look good.

Cam followers should have been ISKY - these have no oil hole and look like mini spares basic version or original, i just dont know

Cam bearings should have been replaced and have not been

Pushrods replaced and checked - found 2 so badly bent i can not believe anyone would fit them

Rocker studs should have been replaced - these are bent and old

Head studs and nuts should have been replaced - studs new but quality unknown and old nuts

Im now very concerned about the crank work and pistons that were also done. I now have to strip everything to inspect. This is not what i need. I should have been completing the engine this week.

IMG_1323.JPG 40.81K

5 downloads

IMG_1323.JPG 40.81K

5 downloads IMG_1324.JPG 40.64K

6 downloads

IMG_1324.JPG 40.64K

6 downloads IMG_1325.JPG 28.65K

3 downloads

IMG_1325.JPG 28.65K

3 downloads IMG_1326.JPG 28.61K

3 downloads

IMG_1326.JPG 28.61K

3 downloads