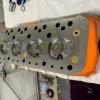

Excuse the black maker pen but I have no engineers blue. The picture shows only a very small contact area. Should this cover the whole angled area?

93119114-FE74-4307-B24B-5ECFDEDA365B.jpeg 80.33K

25 downloads

93119114-FE74-4307-B24B-5ECFDEDA365B.jpeg 80.33K

25 downloads

Posted 30 May 2020 - 02:50 PM

93119114-FE74-4307-B24B-5ECFDEDA365B.jpeg 80.33K

25 downloads

93119114-FE74-4307-B24B-5ECFDEDA365B.jpeg 80.33K

25 downloads

Posted 30 May 2020 - 03:08 PM

How much contact surface area should there be after a new valve has been installed and lapped?

Excuse the black maker pen but I have no engineers blue. The picture shows only a very small contact area. Should this cover the whole angled area?

93119114-FE74-4307-B24B-5ECFDEDA365B.jpeg

Posted 30 May 2020 - 03:51 PM

I was always led to believe that the exhaust valve needed full lap whilst the inlet only need a fine line lap. Is that still true?

Posted 30 May 2020 - 08:39 PM

For road use, you really want no less than 0.060" seat face contact for the exhausts.

Looking at that, I think you'll want to have the seats re-cut, then lap them.

Posted 31 May 2020 - 07:49 AM

Thanks for the replies. Should it be the same contact area for the inlets valve and exhaust valves?

Looks like i will get busy with it today and see if i can improve the contact area, if not i will as advised get them re cut. They were supposed to already be done.

Posted 31 May 2020 - 08:40 AM

Again, for road use, yes, but you can happily go down to 0.040" on the Inlets.

The Exhausts need more to help disperse the heat out of the Valve Head.

Posted 31 May 2020 - 08:46 AM

Posted 31 May 2020 - 10:05 AM

Posted 31 May 2020 - 10:15 AM

E7675D64-FE37-48DC-B788-87E45EF2EE22.jpeg 95.81K

12 downloads

E7675D64-FE37-48DC-B788-87E45EF2EE22.jpeg 95.81K

12 downloads

Posted 31 May 2020 - 10:19 AM

897A5B58-AA89-4935-A6A3-98C5A5FA7484.jpeg 85.6K

3 downloads

897A5B58-AA89-4935-A6A3-98C5A5FA7484.jpeg 85.6K

3 downloads

Posted 31 May 2020 - 10:24 AM

Edited by Turbo Phil, 31 May 2020 - 10:26 AM.

Posted 31 May 2020 - 10:32 AM

Posted 31 May 2020 - 10:46 AM

45980717-4C60-4A30-9102-AFB56EF6952B.jpeg 65.74K

1 downloads

45980717-4C60-4A30-9102-AFB56EF6952B.jpeg 65.74K

1 downloads 37E515CB-2075-4581-9BB6-7DC551F6F4F1.jpeg 90.43K

1 downloads

37E515CB-2075-4581-9BB6-7DC551F6F4F1.jpeg 90.43K

1 downloads

Posted 31 May 2020 - 11:35 AM

Posted 31 May 2020 - 02:23 PM

Thanks again for the info. Im learning a lot today. All valves now lapped and happy with contact area. The valves fitted look like they have been supplied from mini spares. The guides look standard cast iron type but maybe the exhaust enlarged to 8mm. As i have no idea what im doing here but would like to get it correct, what is the correct material used for the guides? I have done some reading and see other materials available. Is the standard cast guide ok for standard boost turbo engine? With the current valves that are fitted. Material not stated on mini spares.

Thanks

Rob

0 members, 1 guests, 0 anonymous users