Hi everyone

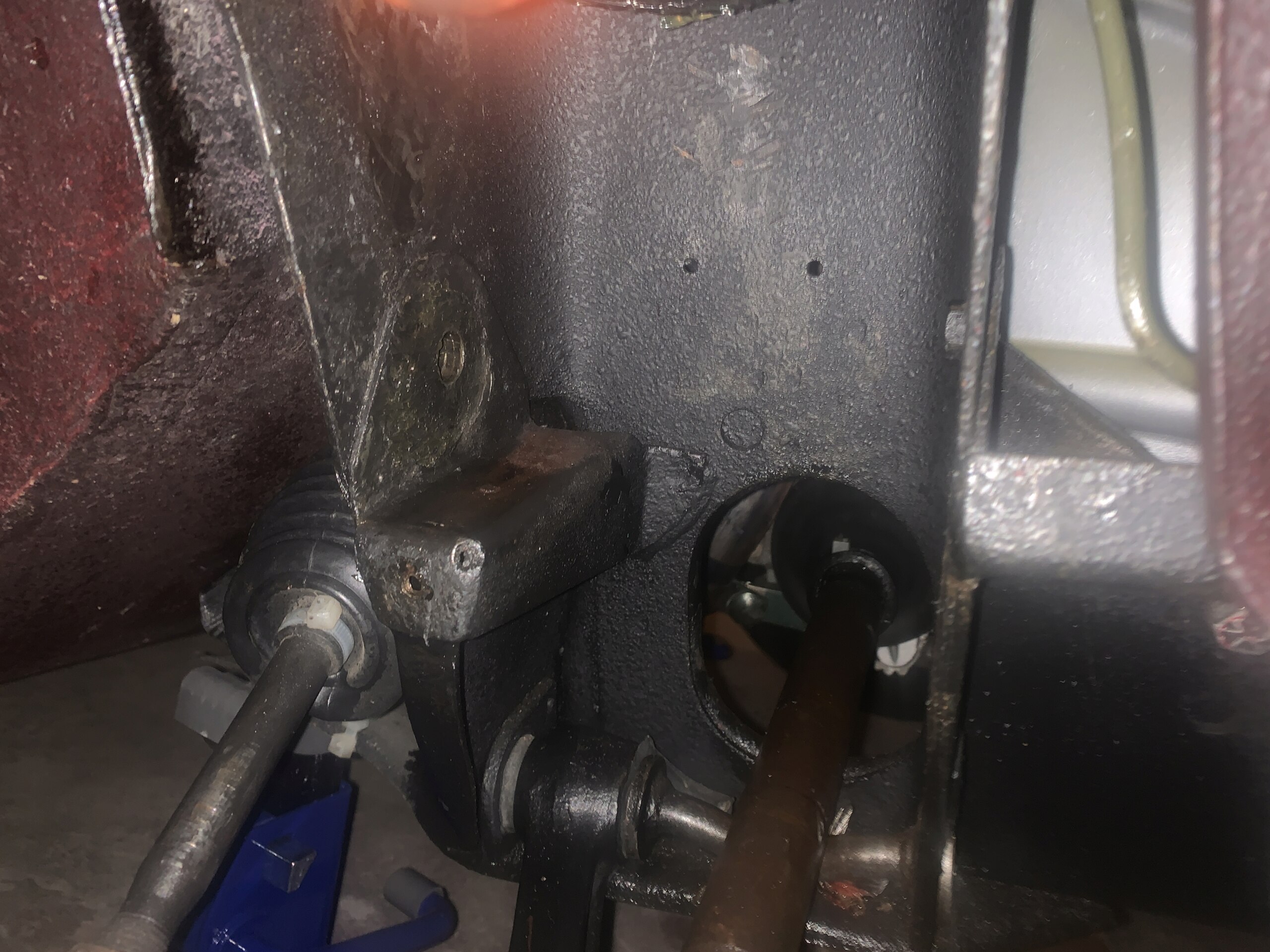

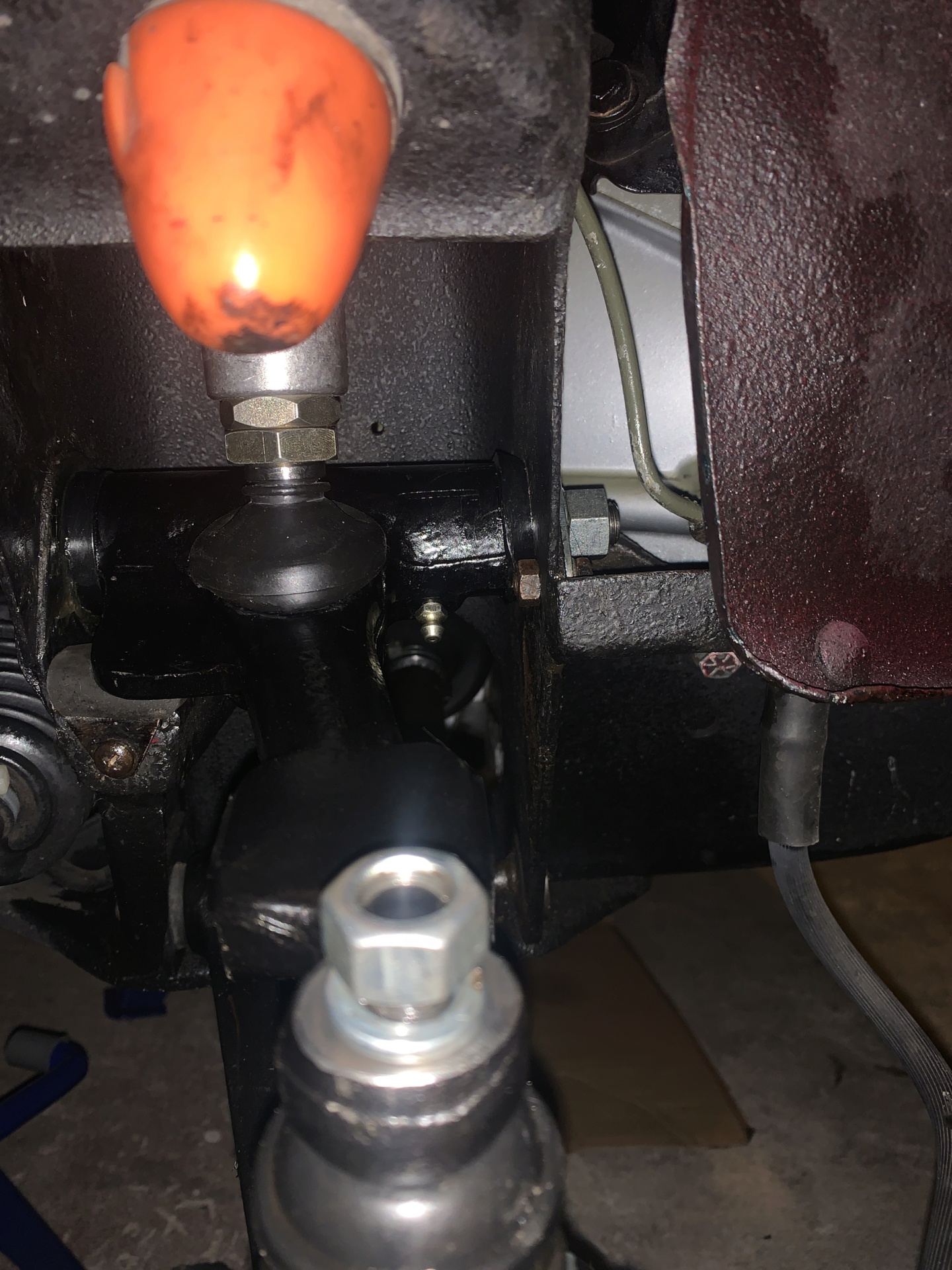

I'm currently rebuilding my front suspension upper arm on my Mini and I'm stuck trying to put it back in place.

I've bought a whole new arm + new joints and dust cover, but when I try to put the arm + the dust cover (passenger side), the joints (both), it does not fit. The engine side joint is not staying in place and it's a pain to achieve it. It looks like I need 1 mm more to work it out. Does anyone get a tips on that?