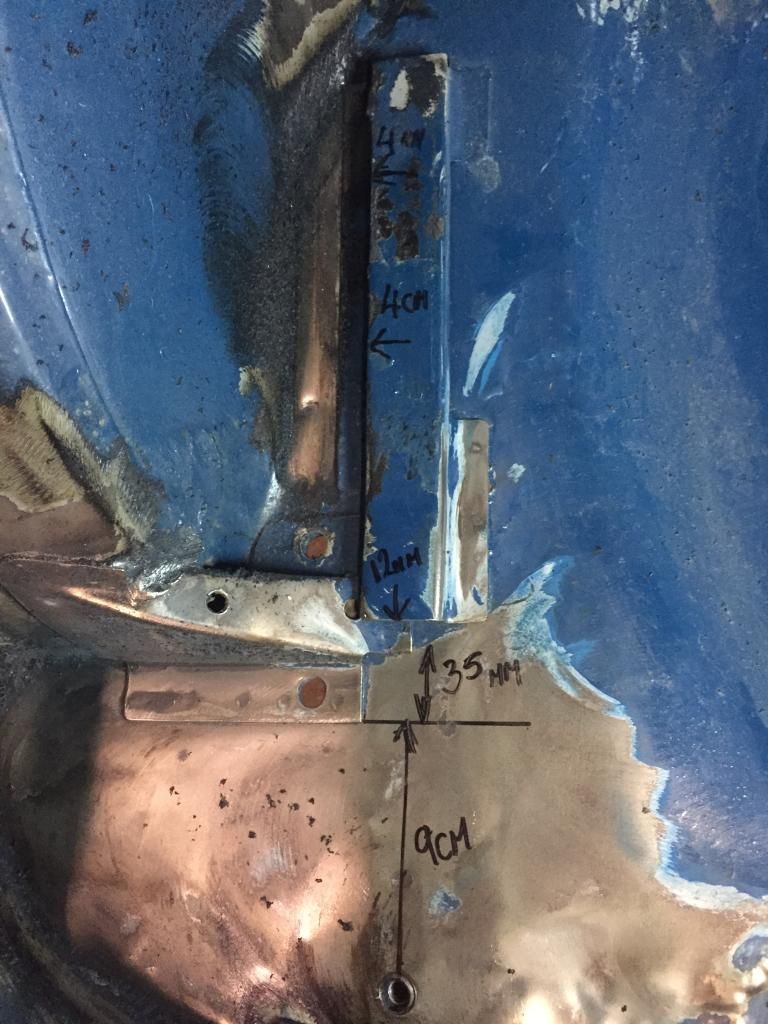

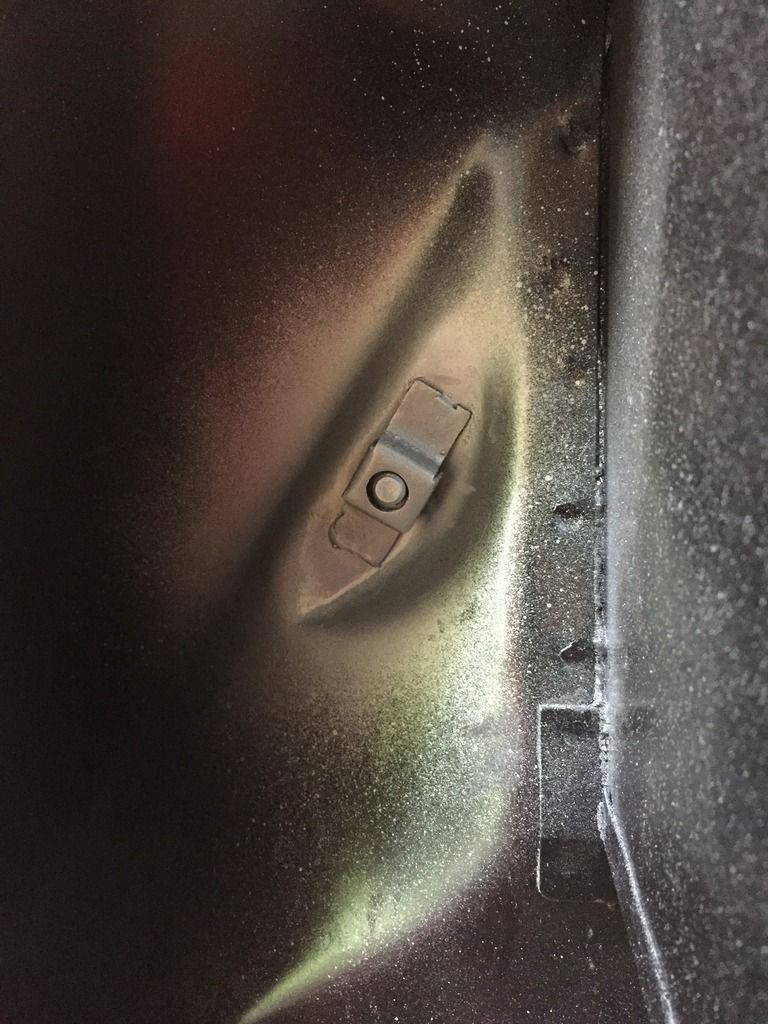

Ive decided to replace the boot floor in my Mark 3. The car is jacked up with the rear subframe removed. I was going to patch but have found that what's there has been repaired so many times that it makes sense to replace with a whole new Heritage panel with battery box. I have seen a few threads on here which have convinced me its possible to get the floor panel out without damaging the rear bulkhead, heal board or wheel arches.

My questions:

1. The BMH boot floor panel seems to be generic to all models? Will it fit in a mark 3 ok? And what non-original features does it have (a different battery box)?

2. Bracing? Any required if only the floor is being removed? My car is currently braced across the doors (ready to do the sills) and jacked up just in front of the heal board. I have seen that some people brace across the arches/turrets but am not sure if this is in the direction of any likely forces from boot floor removal.

3. Any other tips - especially for getting the old floor out without disturbing the bulkhead, healboard and arches.

TIA!