Roller rockers?

#1

Posted 06 September 2004 - 05:51 PM

I've always wondered about full roller rockers and roller tip rockers. Firstly, what is the difference between them? Secondly, what do they do? Am I right in thinking that they just increase the amount the valve opens?

I have a 266 cam fitted at the moment, so what are the implications of fitting full roller rockers or roller tip rockers? Is there any difference in noise or reliability between the two? Will fitting them make a difference in terms of power/torque, and are they worth the money?

Also, I notice there are several different ratios to choose from. Which is best for a lightly modified 1275 engine, with a 266 cam, stage 1 kit, HIF44 carb, slightly ported head but nothing major?

Sorry about all the questions, its just they've always puzzled me!!

Tom

#2

Posted 06 September 2004 - 05:57 PM

#3

Posted 06 September 2004 - 08:34 PM

1.3 i think is the standard ratio (someone correct me if i'm wrong)

This then leaves 1.5 which is a higher ratio so you get more valve lift.

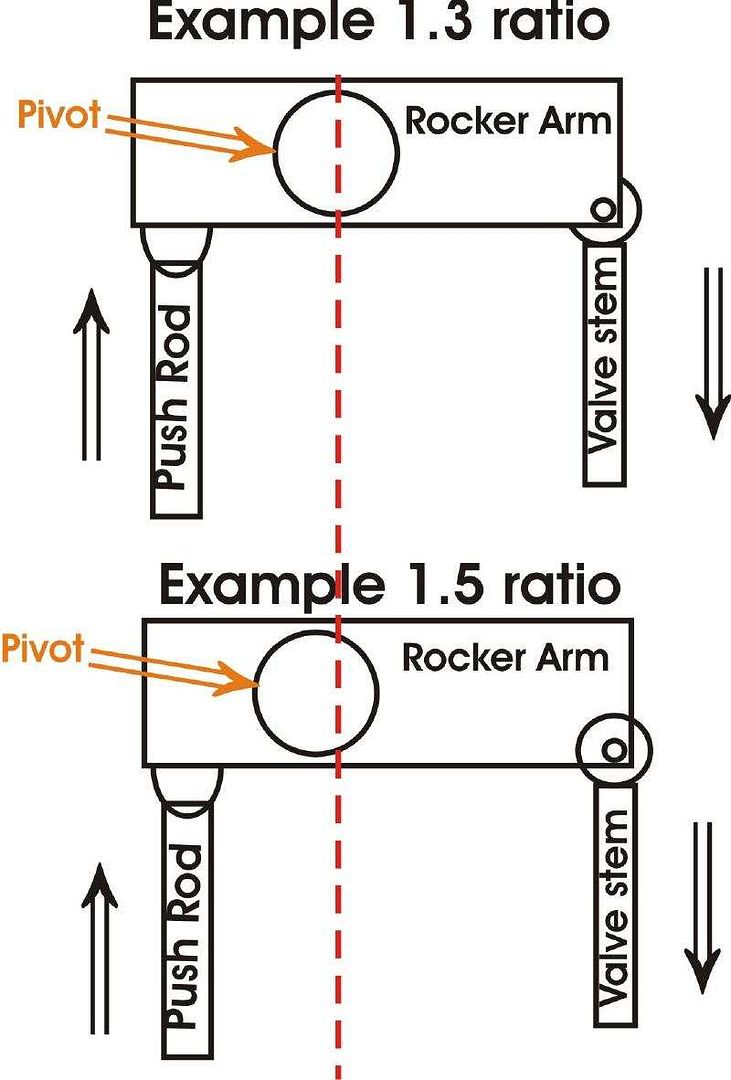

Below is a simple (ish) diagram to show the difference (not exact only an example) between a standard and a high lift rocker.

On the second diagram you get more valve lift because of the change of pivot point which causes the rocker arm to move further with the same input from the push rod (which goes to the cam)

phew!

#4

Posted 07 September 2004 - 02:00 PM

and yes 1.3 is standard...

PS. What ever rocker you use they will not change the duration or timing of the lift, only the speed and amount... ie open and close faster and further with 1.5's (infact approx 15% faster and further )

#5

Posted 07 September 2004 - 04:46 PM

1.3:1 may be standard on later engines but for early 1275s like mine the Cooper-S forged rockers were 1.22:1 (nominal).

I have stock rockers for the moment but someday will install high-lift rockers. A friend of mine with a Spitfire installed the equivalent of 1.5:1 rockers on his 1300 engine. He did some un-scientific time/distance sprints on a local road before and after the installation. He claims to have shaved a couple of seconds off of his 1/4 mile times. Again, it was un-scientific but did show an easily measurable improvement on an engine comparable in size to that of the Mini.

#6

Posted 07 September 2004 - 05:43 PM

Attached Files

#7

Posted 07 September 2004 - 06:01 PM

#8

Posted 07 September 2004 - 07:42 PM

I'm now a firm fan of bolt on power after spending a fortune on my old 998 lump for around 60horses and ending up with a very unreliable engine.

I was also thinking of purchasing a spare head for the mg lump and having it ported, putting better guides in and converting to unleaded. Would a machine shop do this obvoiusly i won't need bigger valves because the mg head is about as big as you'd want to go on a road car anyway so would it be cheaper than buying say a stage 3 head off the shelf?

#9

Posted 07 September 2004 - 10:36 PM

#10

Posted 08 September 2004 - 06:42 PM

#11

Posted 08 September 2004 - 06:53 PM

#12

Posted 08 September 2004 - 07:38 PM

#13

Posted 08 September 2004 - 09:40 PM

plenty of room under the steel lid .

#14

Posted 15 June 2013 - 03:25 PM

I know this subject is a bit long in the tooth now but maybe anyone thinking about fitting roller rockers may be interested in my experiences. I have a 998 Mk2 Cooper which is currently undergoing a ground up rebuild having been seriously abused during the 70s and 80s. Whilst rebuilding the engine I decided to fit roller rockers to reduce the wear on the valve guides. Having acquired a set I began the task of fitting them to the head. On advice of Sean Brown from Flowspeed in America I carried out all the measurements and the shimming to align the roller ends to the valves. So far so good. However, when I lowered the head on to the block and fitted an adjustable push rod in order to ascertain the required length I found that the push rods were not running vertically. I have been unable to find a set of rockers in which the roller end is not offset as the standard arm ball end is in direct line with the centre line of the valve. Does anyone know a manufacturer who makes roller rockers which will fit 12G295 Cooper head? I only want 1:1.3 ratio. Hope someone can help!

#15

Posted 15 June 2013 - 04:48 PM

https://www.somerfor...oducts_id=15000

Minispares do 'em too, but are out of stock, might be worth ringing first.

0 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users