EC66B989-7DCE-4CF2-83BB-14F0466D2449.jpeg 76.87K

2 downloads

EC66B989-7DCE-4CF2-83BB-14F0466D2449.jpeg 76.87K

2 downloads 084855AD-E4EA-4737-AA1B-112223B446AF.jpeg 39.43K

0 downloads

084855AD-E4EA-4737-AA1B-112223B446AF.jpeg 39.43K

0 downloads C944EDCF-0B67-48AC-B7D1-C96C7D7E391E.jpeg 55.7K

0 downloads

C944EDCF-0B67-48AC-B7D1-C96C7D7E391E.jpeg 55.7K

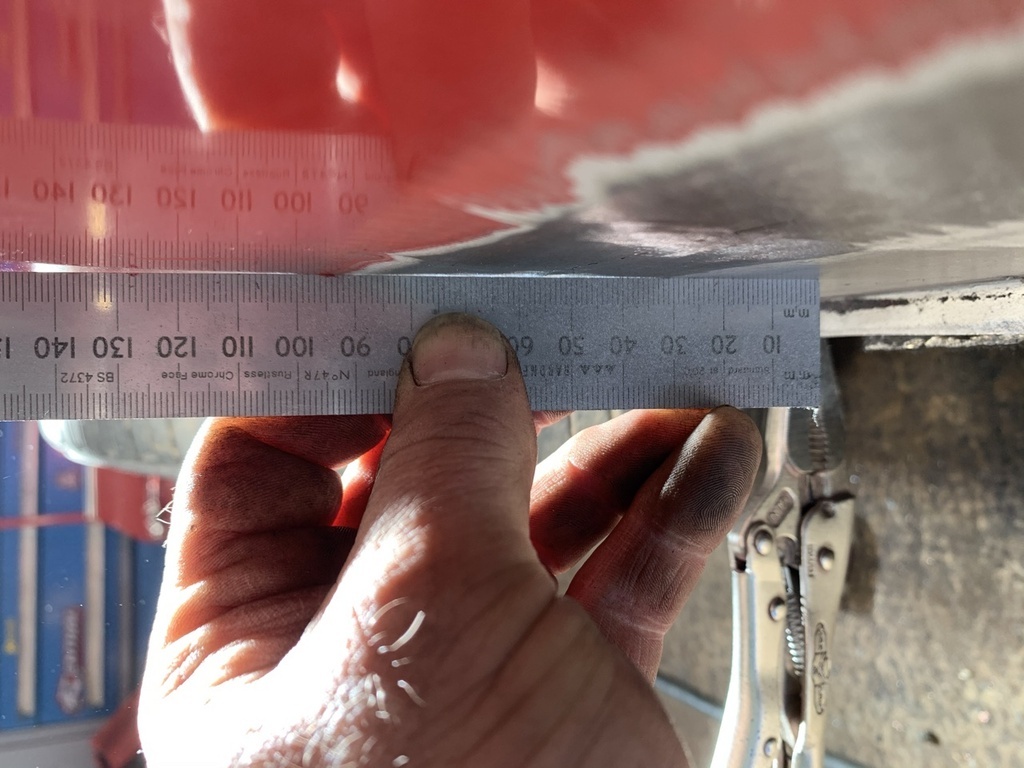

0 downloadsI borrowed a spot welder from a mate, got a few tacks on the frame and test fitted the door. All gaps look good so tomorrow I will complete the door frame install.

03782EEE-96DC-4533-BEB7-940FB3114086.jpeg 69.42K

0 downloads

03782EEE-96DC-4533-BEB7-940FB3114086.jpeg 69.42K

0 downloads 6DB6C645-3C17-40F2-9DBF-738346138BB7.jpeg 52.27K

1 downloads

6DB6C645-3C17-40F2-9DBF-738346138BB7.jpeg 52.27K

1 downloads 0023E3B4-E4CF-4529-A37C-152E1AFF2D80.jpeg 49.89K

2 downloads

0023E3B4-E4CF-4529-A37C-152E1AFF2D80.jpeg 49.89K

2 downloads A950CD3E-8B61-4603-B6F9-F0E88D0D6261.jpeg 51.94K

3 downloads

A950CD3E-8B61-4603-B6F9-F0E88D0D6261.jpeg 51.94K

3 downloads