Thought I'd post about an engine I'm building after watching the Bill Sollis 1380 engine build DVD.

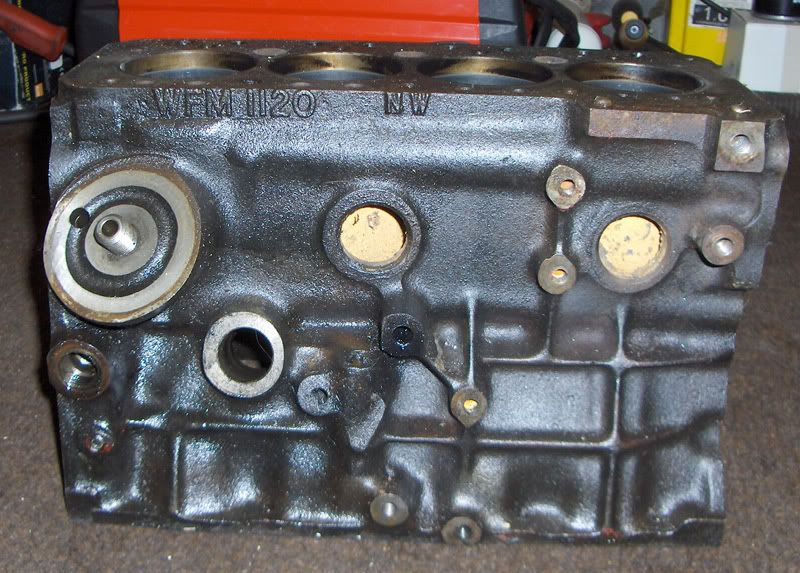

I phoned round a few breakers yards and Common Road breakers(Evesham) said they had a 1275 A+ engine. I watched them drag it out of a massive pile of engines with a chain attached to a forklift. Amazingly it was still intact!

It turns out the engine was off a Maestro or something with a massive gearbox attached but I had a spare Mini gearbox from when I put an MG Metro engine in the Mini and I've seen the weird block used by Brian Calver so I think it should be fine except for a bit of machining on the block.

I had to bin the crank as it wouldn’t take the Mini clutch and I bought a good crank from Min Its for £75.

I hosed the engine down and scrubbed all the parts with Gunk.

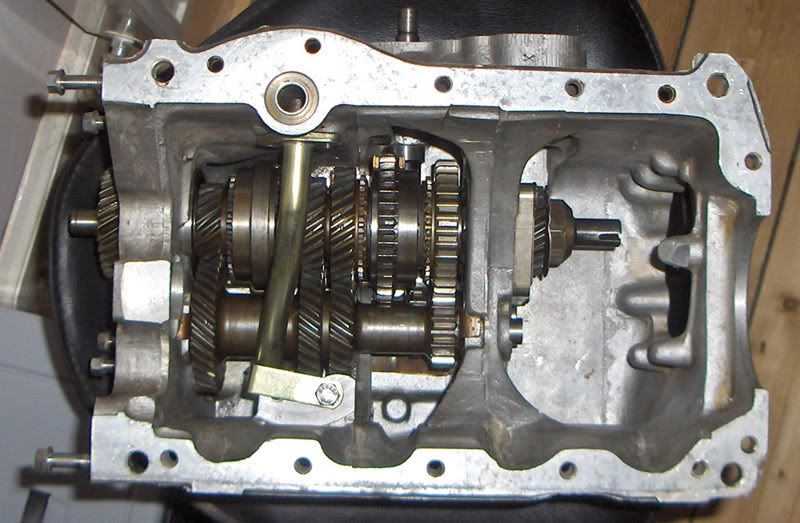

The Mini gearbox needed fixing so I took it apart after watching the Bill Sollis vid about 5 more times and replaced the 2nd gear which had a missing tooth and put a hardened diff pin and center point pick up pipe.

I also added Silicon Nitride balls in that big double bearing in the gearbox. They’re 1/3 the weight of steel, 5 times stronger than steel and much harder. I made a few gearbox parts in grade 5 titanium on my lathe but I think I only saved about 30grammes maximum considering the amount of time it took to make them. They also needed to be accurate to .02mm!!!!

I’m fitting some 73mm Evolution pistons from Minispares giving a 1362cc displacement, because I didn’t really want to go right up to 1380cc after reading about smokey engines and oval bores.

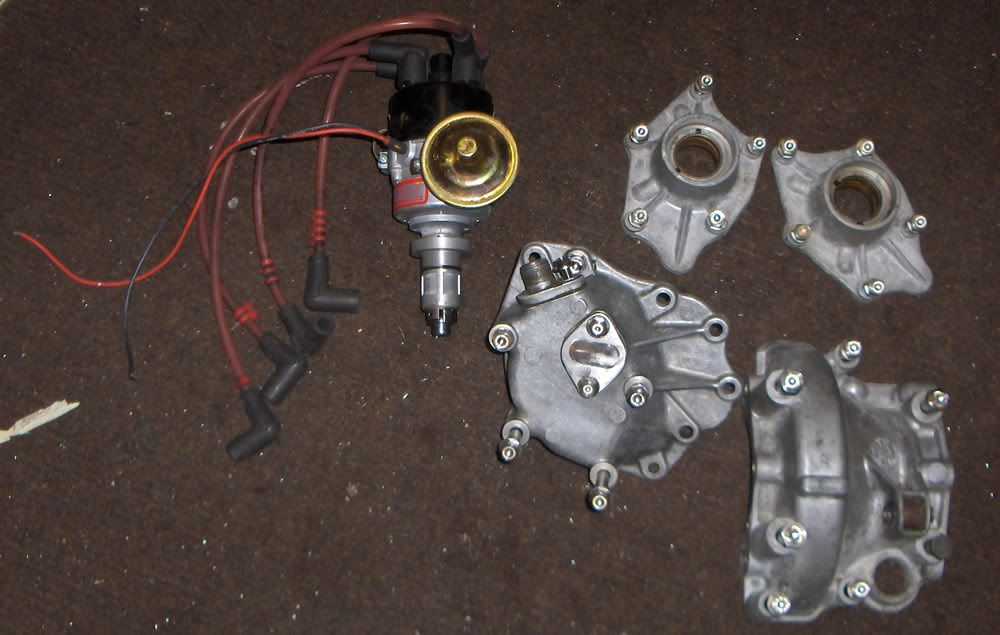

SW5 07 cam with lightweight cam followers with holes in to stop oil collecting in them.

Metro turbo oil pump

MED alloy vernier duplex timing kit.

MED S pulley, which I hoped would be alloy but is steel, so I’ll cover it in Vaseline or grease to stop it rusting.

Stainless steel exhaust manifold from Specialist Components….. NICE!

Swiftune back plate and when I’ve got a spare £300 I’ll get the featherweight Swiftune flywheel made from EN24 steel (CroMo) I checked the metal spec and it’s stronger than grade 5 titanium!

I tried polishing up the bores of the inlet manifold with a bendy drill extension and a ball shaped grinder. It may have worked but probably wasn’t worth an hour of grinding.

When I finally buy all the parts I'm going to get Rob Walker engineering to do all the machine work before painting the block and using titanium nuts, bolts, studs and clevis pins all over the engine and car. It's taken forever to make them all on the lathe but it'll be worth it to stop rust.

I'm hoping for 100hp like the Bill Sollis engine. I thought of turbo but didn't want to cut a big hole in the bulkhead and all the hassle that goes with turbo.

I really didn't think it would end up as expensive as its turned out. I've not bought the head and drop gears yet.

Cheers,

rich