Oil Fed Engine Thrust Bearing Conversion

#1

Posted 16 May 2010 - 10:59 AM

I am building a 1380 pre A+ with a 16 valve BMW head, for my brother inlaw, using bits and piece from specialist components

I have heard an option to improve thrust life is to modify the engine oiling to feed oil to the clutch side thrusts to improve there life when running a heavier clutch cover.

Does anyone know what's involved in the modification. As I have plenty of other prep work to do on the block for the BMW head a little more machining does not worry me.

1978 clubman

originally a 998

#2

Posted 16 May 2010 - 11:04 AM

Hi Guy's,

I am building a 1380 pre A+ with a 16 valve BMW head, for my brother inlaw, using bits and piece from specialist components

I have heard an option to improve thrust life is to modify the engine oiling to feed oil to the clutch side thrusts to improve there life when running a heavier clutch cover.

Does anyone know what's involved in the modification. As I have plenty of other prep work to do on the block for the BMW head a little more machining does not worry me.

1978 clubman

originally a 998

#3

Posted 16 May 2010 - 04:07 PM

#4

Posted 16 May 2010 - 04:17 PM

#5

Posted 16 May 2010 - 04:18 PM

a grey pressure plate will normally be ok esecially if on an engine that dosent see to many miles, but the double greys used on turbo engines seem to give thrust trouble probably because they see more road miles.

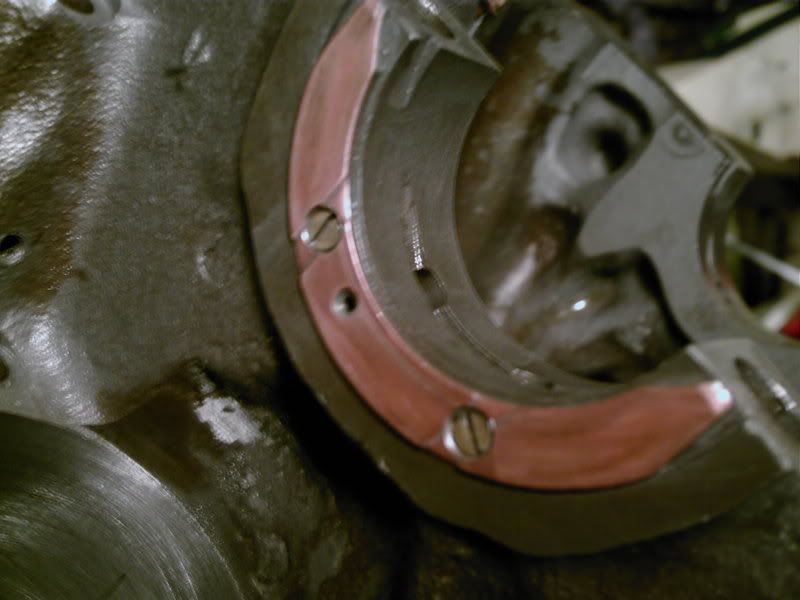

esentially you drill the thrusts and screw them to the block, and drill through to the oilway that feeds the centre main.

there is a picture in this thread.

http://www.theminifo...x...6382&st=210

#6

Posted 16 May 2010 - 05:18 PM

#7

Posted 16 May 2010 - 05:22 PM

#8

Posted 16 May 2010 - 05:58 PM

#9

Posted 16 May 2010 - 11:43 PM

Hi Guy's,Flow finds the easiest route.... and the easiest route being the one without any load

Thanks that some it up. Mra-mini's I think the drilling is done only on the clutch thrust side to encourage the oil out in that direction and it will just leak out through the main sheel as per normal to the front.

Cheers,

Craig.

#10

Posted 17 May 2010 - 06:31 AM

Hi Guy's,Flow finds the easiest route.... and the easiest route being the one without any load

Thanks that some it up. Mra-mini's I think the drilling is done only on the clutch thrust side to encourage the oil out in that direction and it will just leak out through the main sheel as per normal to the front.

Cheers,

Craig.

Yes I would agree with that...

However as Cooperman says its the duration that kills the thrusts. The pressure of course has an adverse affect which would accelerate trhe wear, encouraging oil to migrate to a position associated with high wear has to be a good thing

Although with 14psi a double grey would not be required

#11

Posted 17 May 2010 - 06:53 AM

The clearance on the mains, big-ends and cam bearings is much less than that on the thrusts. Will having an oil feed to a bearing with such a large clearance lead to a loss in oil pressure to the rest of the engine? This could be controlled by carefully sizing the drilling to the thrusts, but I was wondering if this issue had been taken into consideration?

Edited by pogie, 17 May 2010 - 06:54 AM.

#12

Posted 17 May 2010 - 02:58 PM

The screws are also countersunk well below the actual bearing surface of the thrust bearings, so should never come into contact with the crank during the serviceable life of the thrusts.

I have seen in the past people use brass screws in case they ever come loose. We have threadlocked our steel ones in place.

If you are interested in this mod I suggest you visit:-

http://www.force-racing.co.uk

Edited by John H, 17 May 2010 - 02:58 PM.

#13

Posted 17 May 2010 - 03:03 PM

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users