Ill give you a bit of a catch up to where i am now and ill try to keep it updated as much as i can and im sure ill be needing some help and support along the way because im sure its not goin to be easy!

Right, i bought this little bad boy back in Feb 2009 for the tidy sum of £500, thought it was a right BARGAIN!

It was in really good condition and had had a few quid already spent on it, mainly on the engine...it had a 1330 race spec engine, not my cup of tea but it went well!

First job was to strip the thing down, right down to a bare shell!

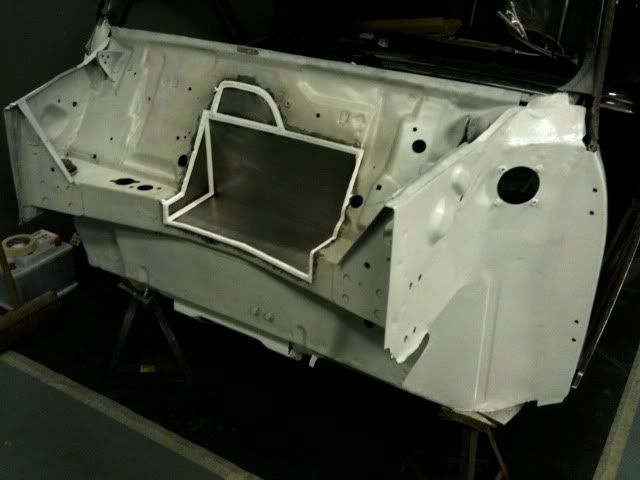

After a long six months of welding in my garage, including two new front floorpans, two new sills, repair panels to the boot floor and rear valance the decision was made to go for the 16v route! I wasted no time and got the front end chopped off before i changed my mind!

Had a little break for a few months over christmas and moved house to an apartment with no garage so it slowed me down a bit, and the hunt for a unit began. Luckily in March we managed to find a unit and time came for the Mini to be moved to its new home...you wouldnt believe what we transported it in!!!

Yep, up stepped my mate and his BIG van! Couldnt believe it when he suggested it and it actually worked, it fitted perfectly! Here's the bad boy now sat in the unit ready for the work to begin...

Next step was to get it up on its side, always good to see a mini on its side, and the only way to do it properly i think. Got my mate round with the compressor and got a good coating of stonechip on there! Really good to see it like this, feels like your gettin somewhere and looks mint...

Had another break from mine for a few weeks because we had my mates 1275 GT back from the bodyshop and had 2 weeks to put it back together before London - Brighton. Really didnt think it was gin to happen but it did, and it looked the dogs even if i do say so myself! Check his build out at

http://www.theminifo...howtopic=120525

Right back to mine and it was time to give the underside a bit of colour, went for gloss white as i think im goin for BMW Alpine White as my final colour choice. Lookin good!!!

To be fair thats pretty much where i am, i know it doesnt look much but trust me, so much time and effort is goin into this. Im hoping to have this done for next years London - Brighton so lets get moving...

I have been out buying the last couple of weeks, much to the mrs disgust! I ordered myself an Allspeed VTEC frame last tuesday so should be here on the 15th. I got a bit impatient waitin for the frame so i went and got myself this beast ready to drop in...

God it looks SEXY! Goin to be sooooo good! Here it is as it is now, back down on its belly and ready for the frame and engine to be trial fitted next week.

And thats it for now, let me know what you think, ill try and keep it updated as much as i can, so check back for progress...

Hope you like...