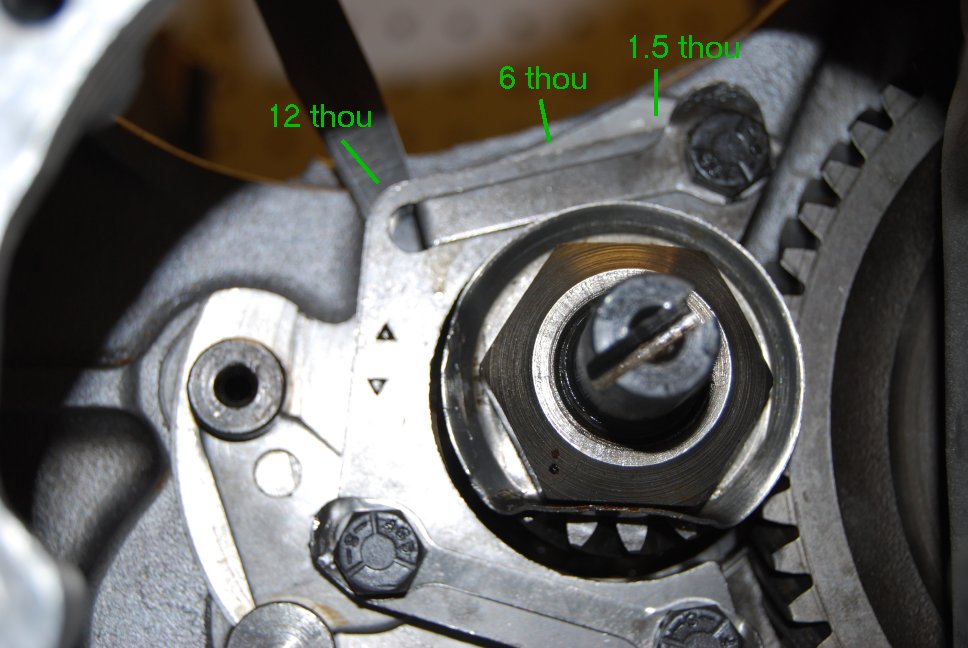

I'm doing a little work to my gearbox, and needed to remove the layshaft. When I refitted it I thought it wise to check the shimming. The 3rd motion retainer has stumped me. It wasn't shimmed to start with, and when I fit it the gap I'm measuring is tapered... goes from 12 thou to 1.5 thou along the top edge (see pic). Can someone tell me...

a) is this normal... and if not how do I correct it?

b) at which point should I take the measurements?

c) what size shim(s) do I need (and what part number... e.g. a couple of 2A3714's)?

Cheers,

Colin.