12g940 On A 998

#1

Posted 21 February 2011 - 09:28 PM

Im after some advise on the coolant passages on the block. Do i just tap the hole and stick a grub screw or bolt in it or do i need to re drill the hole to line up with the 12g940 head?

Anyone had any overheating problems if not drilled? Drilling seems to be a problem as it needs to be flush to seal?

thanks

#2

Posted 21 February 2011 - 11:18 PM

#3

Posted 22 February 2011 - 02:09 AM

#4

Posted 22 February 2011 - 12:16 PM

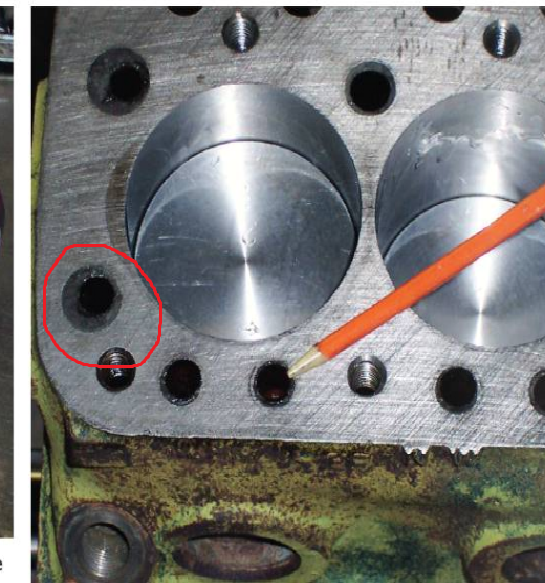

This one

#5

Posted 22 February 2011 - 12:33 PM

I have it on good authority you have to block up 1 water passageway, this is to stop pressurisation of the head causing failure, you can get away with not doing it though, personal preferance, I chose to do it in the end

This one

Yep you have to block off that hole, I tapped it a plunged it. I still had trouble with it blowing from the cylinder, in the end I welded it up and had the block skimmed

#6

Posted 23 February 2011 - 12:45 AM

#7

Posted 23 February 2011 - 03:00 AM

#8

Posted 23 March 2011 - 08:53 PM

as you can see the gasket leaves shadows of water passages of head on block.

must i redrill the holes to allign the heads holes or will it be ok?

the head comes from a cooper engine, i dont know if the cooper block has bigger water passages to fit with the head

water passages look like with those of the 12g940, if i redrill the passages on the block ill need to put a water pump from 1275 (bigger holes, needs bigger flow?)?

sorry if i posted in a wrong thread but on searching i find this to be more related to my issue

Attached Files

Edited by full metal mini, 23 March 2011 - 09:06 PM.

#9

Posted 23 March 2011 - 09:07 PM

#10

Posted 23 March 2011 - 09:21 PM

do you think its ok for a cruising set up?

#11

Posted 23 March 2011 - 10:50 PM

im trying to get a 9:1

do you think its ok for a cruising set up?

9:1 sounds okay, I don't think you'd want more than 10:1 for a daily driver. Have you worked out the ratio exactly though? I'm no expert on this subject, but it is good to know what compression you are running.

#12

Posted 24 March 2011 - 09:58 AM

And - i've never blocked off any waterways when doing the 940 head on a small bore block.........

Edited by bmcecosse, 24 March 2011 - 10:00 AM.

#13

Posted 24 March 2011 - 06:59 PM

The question now is....Do i block this waterway up or not?

#14

Posted 25 March 2011 - 04:51 PM

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users