Cv Shaft Wear. What Is Acceptable?

Started by

mini670

, Dec 29 2011 08:20 PM

10 replies to this topic

#1

Posted 29 December 2011 - 08:20 PM

Inspecting a CV joint today. The shaft is worn 0.02mm (just under a thou) on diameter on the bearing positions. Would this be ok to reuse?

Also id like to ask if you know about it when the actual cv is worn, ie sloppy feel to it. One last thing, please. I can`t remember seeing and oil flingers on my inner pots, though Haynes (69 - 82) states they should be fitted (mine is 91).

Cheers

Also id like to ask if you know about it when the actual cv is worn, ie sloppy feel to it. One last thing, please. I can`t remember seeing and oil flingers on my inner pots, though Haynes (69 - 82) states they should be fitted (mine is 91).

Cheers

#2

Posted 31 December 2011 - 03:30 AM

I am not sure that I understand where you are measuring the wear. The shaft of the CV does not contact the bearings. The hub flange fits inside the bearings, and a thou means the flange is scrap, as the bearings will rotate on it. If you mean the 6 balls in the CV, they don't contact the shaft either.

But the thing which generally gives trouble is the cage, because if it is not keeping the balls all in one plane, bisecting the angle between the two shafts, the balls tend to lock, which is why you get a nasty clicking noise. But if the cage breaks, beware! It happened to me once, but not on a Mini. It took all my strength to partially control the steering till I had stopped. You really do not wanty to experience massive steering kickback six times per wheel rotation.

That is why I would look at the cage very carefully. It is not likely to actually break on a Mini, but if the balls have left noticeable wear on the sides of their slots, it is not really usable.

A small amount of wear on the inner and outer members is probably OK, provided it is smooth with no pitting. But CVs are not that expensive compared to many other costs involved in running an older car, so it is hardly worth while risking having to strip it down again if a doubtful CV turns out to be bad. If it clicks while cornering, change it.

But the thing which generally gives trouble is the cage, because if it is not keeping the balls all in one plane, bisecting the angle between the two shafts, the balls tend to lock, which is why you get a nasty clicking noise. But if the cage breaks, beware! It happened to me once, but not on a Mini. It took all my strength to partially control the steering till I had stopped. You really do not wanty to experience massive steering kickback six times per wheel rotation.

That is why I would look at the cage very carefully. It is not likely to actually break on a Mini, but if the balls have left noticeable wear on the sides of their slots, it is not really usable.

A small amount of wear on the inner and outer members is probably OK, provided it is smooth with no pitting. But CVs are not that expensive compared to many other costs involved in running an older car, so it is hardly worth while risking having to strip it down again if a doubtful CV turns out to be bad. If it clicks while cornering, change it.

#3

Posted 01 January 2012 - 10:20 AM

Thank you for the reply.

I did not explain it correctly. Its worn a thou in two places on the shaft, where it passes through the two inner races of the wheel bearing. In the middle where the spacer ring is the shaft is not worn at all which is how i made the comparison and calculated the wear.

I did have replacement cv joints for both sides.....but very very stupidly i lost concentration and put the cv on the wrong end of the shaft (i feel like an idiot). Now you would think that it would be easy enough to remove it and put it back on the right end. Nope i have spent hours on it and cant get it off. Think i know why it wont come off, ill try to explain. The chamfer that squeezes the c-clip down when installing the cv is much smaller on these new joints compared to the ones fitted by Rover.

The chamfer is actually smaller (at its largest diameter) than the c-clips diamter. Getting the joints on was a nightmare, it took hours, i eventually did it by applying pressure and manipulating the clip with a small screwdriver into the start of the chamfer. With this in mind im presuming the chamfer on the inside is also on the small side which is why it wont come back off? phew....hope that`s readable ^

I did not explain it correctly. Its worn a thou in two places on the shaft, where it passes through the two inner races of the wheel bearing. In the middle where the spacer ring is the shaft is not worn at all which is how i made the comparison and calculated the wear.

I did have replacement cv joints for both sides.....but very very stupidly i lost concentration and put the cv on the wrong end of the shaft (i feel like an idiot). Now you would think that it would be easy enough to remove it and put it back on the right end. Nope i have spent hours on it and cant get it off. Think i know why it wont come off, ill try to explain. The chamfer that squeezes the c-clip down when installing the cv is much smaller on these new joints compared to the ones fitted by Rover.

The chamfer is actually smaller (at its largest diameter) than the c-clips diamter. Getting the joints on was a nightmare, it took hours, i eventually did it by applying pressure and manipulating the clip with a small screwdriver into the start of the chamfer. With this in mind im presuming the chamfer on the inside is also on the small side which is why it wont come back off? phew....hope that`s readable ^

#4

Posted 01 January 2012 - 10:35 AM

Have you smacked it hard with a rubber mallet?

#5

Posted 01 January 2012 - 10:41 AM

rubber mallet, deadblow, copper, hyde, and BIG hammer lol. think its one for good!

#6

Posted 01 January 2012 - 01:07 PM

You do need to get that off and fit one of the new joints. I forgot that with disc brakes, which you must have, the bearings do fit directly onto the shaft, and the hub flange is basically loose. Your shaft wear is sufficient to make the joint scrap, because the bearings will rotate on it. Probably the hub nut has been inadequately torqued at some time.

The problem with the locking clip may be that the inner part of the CV has become reversed. There should be a proper chamfer on one side only, and as you now know, that side should face the inside of the joint.

To recover the shaft without damage, as the shaft is reversed you could try the tool for removing the inner pot joint from the shaft, 18G1243, which engages with a groove in the shaft at what should be near the outer end, and uses two bolts to jack the inner pot off. Steady pressure is possibly better than hammer blows. But if there is chamfer of less than half the spring clip wire diameter, I don't see how it would help. (By the way, if you can ever acquire the tool, it makes engine out jobs very easy, as it pops the shafts out of the inner pots in situ, no need to drain oil, or dismantle and regrease the pots.)

I fear that this will be an angle grinder job, unless you have a lathe. You need to cut through the outer wall of the CV, just clear of the end of the stuck driveshaft, and release the clip manually from the back. It is a lot of cutting.

Another way, which worked for me on a Talbot Express van (CV inner fitted backwards, probably in the factory!), was to deflect the shaft to its extreme angle, and using the most brutal tools available, attack the ball cage, which was relatively brittle. Once the cage was smashed, the balls could be persuaded out, or pushed to the back, so the now ruined (it was unserviceable anyway) joint would come apart. Then releasing the clip was simple.

Needless to say, the new CV went on correct way round!

I wish you every success with what is probably going to be a couple of hours hard work, whichever way you proceed.

The problem with the locking clip may be that the inner part of the CV has become reversed. There should be a proper chamfer on one side only, and as you now know, that side should face the inside of the joint.

To recover the shaft without damage, as the shaft is reversed you could try the tool for removing the inner pot joint from the shaft, 18G1243, which engages with a groove in the shaft at what should be near the outer end, and uses two bolts to jack the inner pot off. Steady pressure is possibly better than hammer blows. But if there is chamfer of less than half the spring clip wire diameter, I don't see how it would help. (By the way, if you can ever acquire the tool, it makes engine out jobs very easy, as it pops the shafts out of the inner pots in situ, no need to drain oil, or dismantle and regrease the pots.)

I fear that this will be an angle grinder job, unless you have a lathe. You need to cut through the outer wall of the CV, just clear of the end of the stuck driveshaft, and release the clip manually from the back. It is a lot of cutting.

Another way, which worked for me on a Talbot Express van (CV inner fitted backwards, probably in the factory!), was to deflect the shaft to its extreme angle, and using the most brutal tools available, attack the ball cage, which was relatively brittle. Once the cage was smashed, the balls could be persuaded out, or pushed to the back, so the now ruined (it was unserviceable anyway) joint would come apart. Then releasing the clip was simple.

Needless to say, the new CV went on correct way round!

I wish you every success with what is probably going to be a couple of hours hard work, whichever way you proceed.

#7

Posted 01 January 2012 - 02:15 PM

The wheel bearings are secured by the hub nut squeezing them, and the spacer, very tightly between the drive flange & the shoulder of the CV joint. Any wear around the CV splines would show by the hub nut unscrewing, or maybe vibration if the CV gets off centre. How much play in the joint is acceptable is open to debate but it will show mostly when the wheels are near full lock and you're driving hard.

#8

Posted 01 January 2012 - 08:27 PM

Ethel,

That is the theory, but I have seen several vehicles including a Mini, a Maestro and a Focus where relative movement had been happening. (The Maestro was the worst by the way, and I don't suggest that its hubs were one of Rover's finest designs.) The hub and bearing design was different in each case. I guess that none of them had been torqued properly. But I have also seen others, again including Minis, where there was no wear at all on the mating faces.

Once there is measurable wear, correct torquing will no longer prevent movement. But it might be ok in the short term, if you don't mind doing the job again fairly soon.

That is the theory, but I have seen several vehicles including a Mini, a Maestro and a Focus where relative movement had been happening. (The Maestro was the worst by the way, and I don't suggest that its hubs were one of Rover's finest designs.) The hub and bearing design was different in each case. I guess that none of them had been torqued properly. But I have also seen others, again including Minis, where there was no wear at all on the mating faces.

Once there is measurable wear, correct torquing will no longer prevent movement. But it might be ok in the short term, if you don't mind doing the job again fairly soon.

#9

Posted 01 January 2012 - 08:36 PM

Cheers guys.

Today I have found a spare driveshaft that i had bought in a job lot and forgot about, so for the time been the joint can stay where it is on the other shaft.

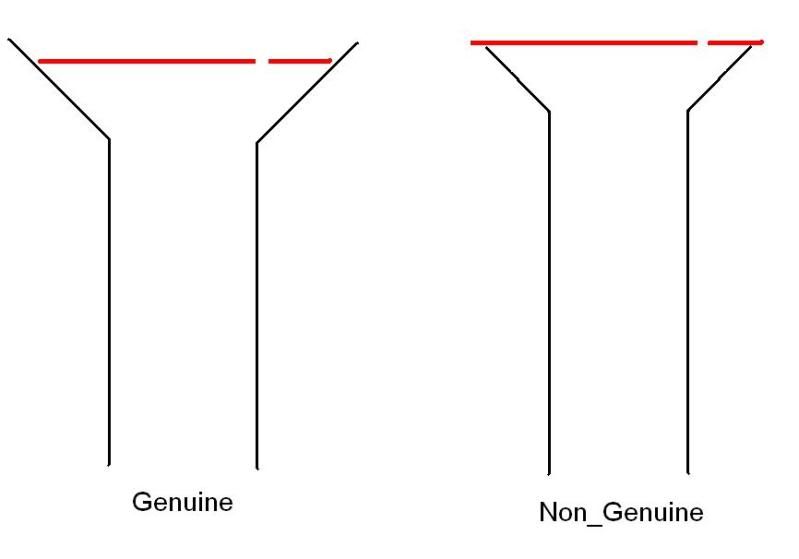

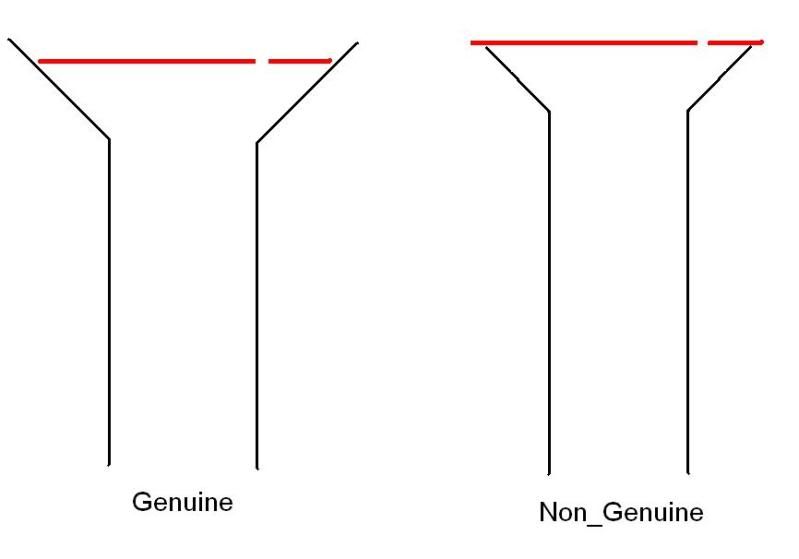

Im not fully understanding the reversed inner though. Looking at one i took off, it has a nice big chamfer larger than the clip (on the outside), i tried it and it slipped on without too much effort (i could literally feel the clip closing up as i shoved it on, no small screwdriver requird to get this one on). It also came back off fairly easily after a few good whacks.

If the clip is a larger diameter than the chamfer reversed or not it would not come off???

Heres a quick paint drawing (exaggerated) to show what i have on the outside of the joint. God knows if theres a chamfer inside or not, cant get me finger in due to the stuck shaft.

Today I have found a spare driveshaft that i had bought in a job lot and forgot about, so for the time been the joint can stay where it is on the other shaft.

Im not fully understanding the reversed inner though. Looking at one i took off, it has a nice big chamfer larger than the clip (on the outside), i tried it and it slipped on without too much effort (i could literally feel the clip closing up as i shoved it on, no small screwdriver requird to get this one on). It also came back off fairly easily after a few good whacks.

If the clip is a larger diameter than the chamfer reversed or not it would not come off???

Heres a quick paint drawing (exaggerated) to show what i have on the outside of the joint. God knows if theres a chamfer inside or not, cant get me finger in due to the stuck shaft.

#10

Posted 01 January 2012 - 08:39 PM

Simple check is to fit a drive shaft - and then measure the endfloat in the cv joint. A new joint has virtually none. I would say anything more than 1/8" means the cv is junk. I wouldn't worry about 1 thou on the bearing diameter - it will be fine on a warm day - and is your measuring instrument in current calibration??

#11

Posted 01 January 2012 - 09:10 PM

cheers,

The mic does need checking actually, have to take it to work and check it against some slips.

The mic does need checking actually, have to take it to work and check it against some slips.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users