My little '94 Mini Mayfair has started leaving some pretty big puddles of oil on the floor

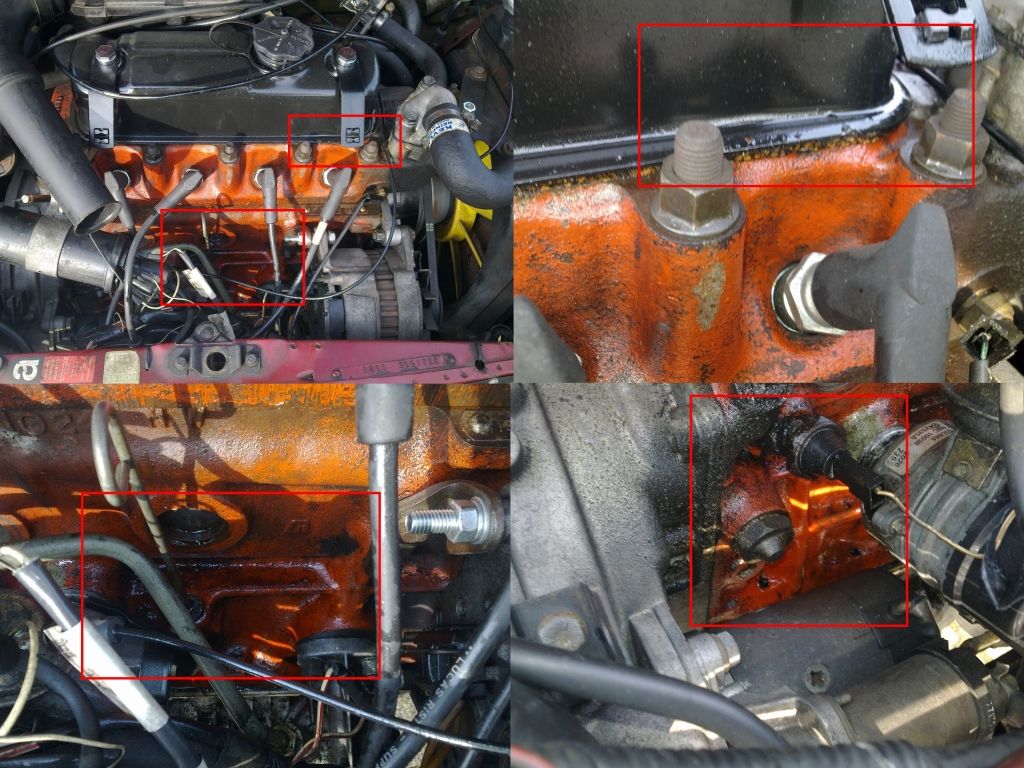

I have sat with her running for a while and watched very carefully, and have spotted one area in particular where I could see the oil dripping and believe that this may be the "problem area" on my car... however I do not know what this object is that it is leaking from. It looks like some kind or engie sensor, as it is an electrical cable that attaches to a bolt which seems to be going into my engine, and the oil is literally dripping off this bolt. I have put a picture below which shows my whole engine, then a slightly more zoomed in pic, then even more zoomed in, until you can see the bolt with the oil dripping off.

Can anyone help me first in identifying this bolt and what it does? And secondly, advise me if this is something I will be able to fix myself or if it will need to go to a garage. Please explain this to me as if I am a 5 year old, because (as much as I try to pretend I know what I am talking about) and am quite new to minis and am not a mechanic. Any help at all would be much appreciated.

Thanks in advance!