Posted 04 August 2012 - 06:21 PM

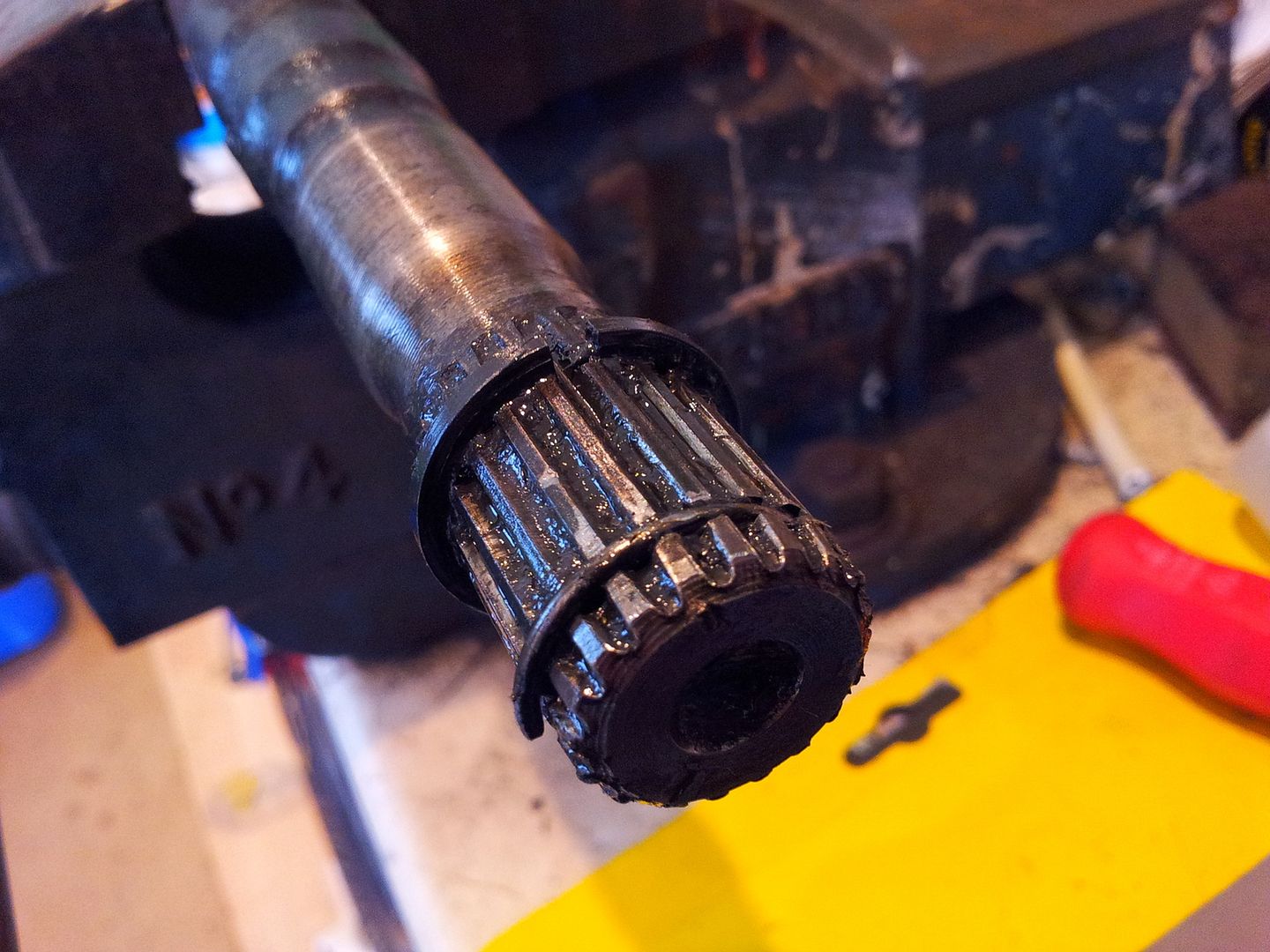

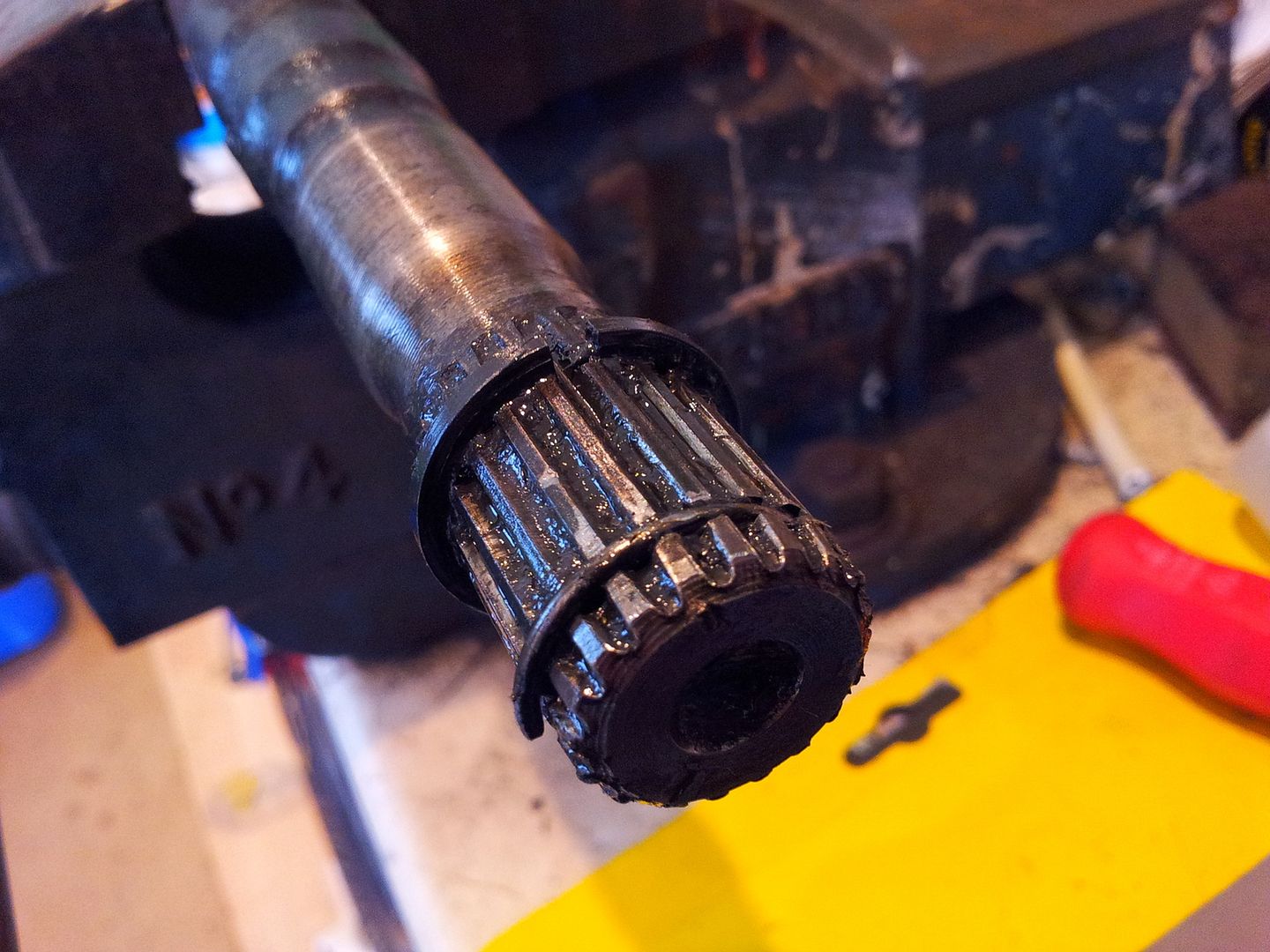

The large circlip is absolutely essential, and if damaged must be replaced. It might be dangerous to drive without it, as in extreme cases the end of the shaft might jam the CV, or if the shaft moves too far outboard, the inner pot joint might spit out its balls. The worst possible thing would be a spinning drive shaft thrashing about, hopefully not very common. Usually there is no need to remove it, which is why there is not one in the kit. Just clean and check carefully for damage, spares are available.

The groove for this circlip is obviously at a point on the shaft which transmits torque, unlike the small clip, and causes a stress raiser which results in fatigue fracture of the shaft if the engine is highly tuned and used hard. In there circumstances, a "competition" shaft without the machined groove is used, and a washer is welded on in the correct position instead. Whoever thought that one up probably failed to consider the effects of the welding on the shaft, as I have heard that they also break. Don't try doing it at home, the washer would need to be of the correct steel, and be welded with low hydrogen electrodes, and I think that the driveshaft steel is rather special too.