Posted 27 October 2012 - 12:33 PM

Ooops, never noticed that it was already off! And yes, it would be a very rare thing to find a heelboard end was needed, but the inner sill was perfect. In fact it would be well-nigh impossible.

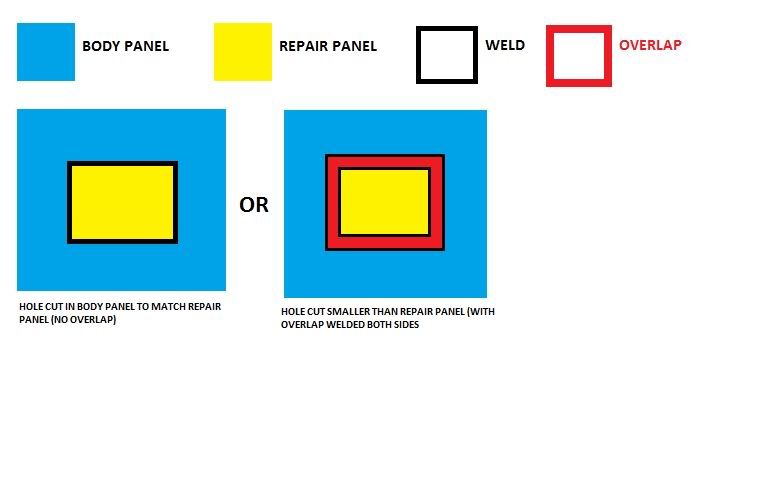

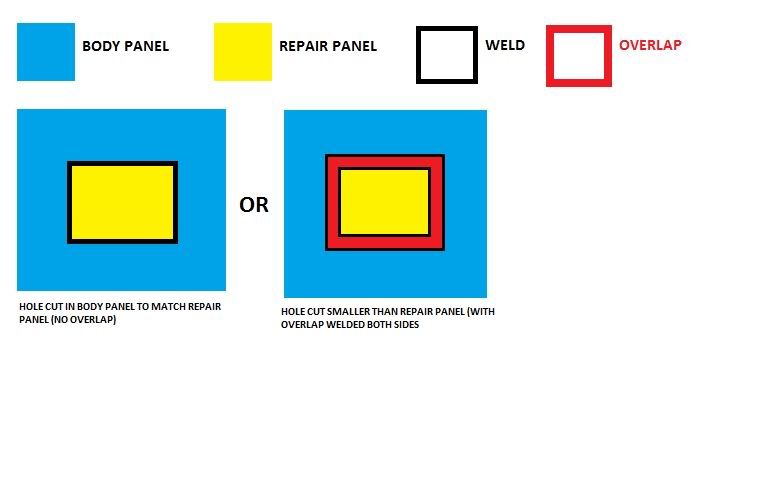

As to the welding, I agree with the various views that butt welds are best, where possible, as they do not form an extra water and rust trap. Anyone with a steady hand, a bit of common sense, and the right equipment for inexperienced users (good, cheap MIG such as Clarke, the thinnest MIG wire, Argoshield Light or other brand of 95% Argon gas, and lots of offcuts of 0.9mm steel for practice, and maybe even the "cheat's tool", the copper backing bar) can learn to do decent butts, so there is no reason to avoid them.

I always feel that it is more useful in the long run to encourage people to learn to do it the best way rather than suggesting that they use a much less satisfactry method, just because it seems easier at the time. Skills acquired can be used more than once in a lifetime, and most people will be able to do this.