1275 Cooper S Rebuild Questions

#1

Posted 18 December 2013 - 07:56 PM

#2

Posted 18 December 2013 - 10:05 PM

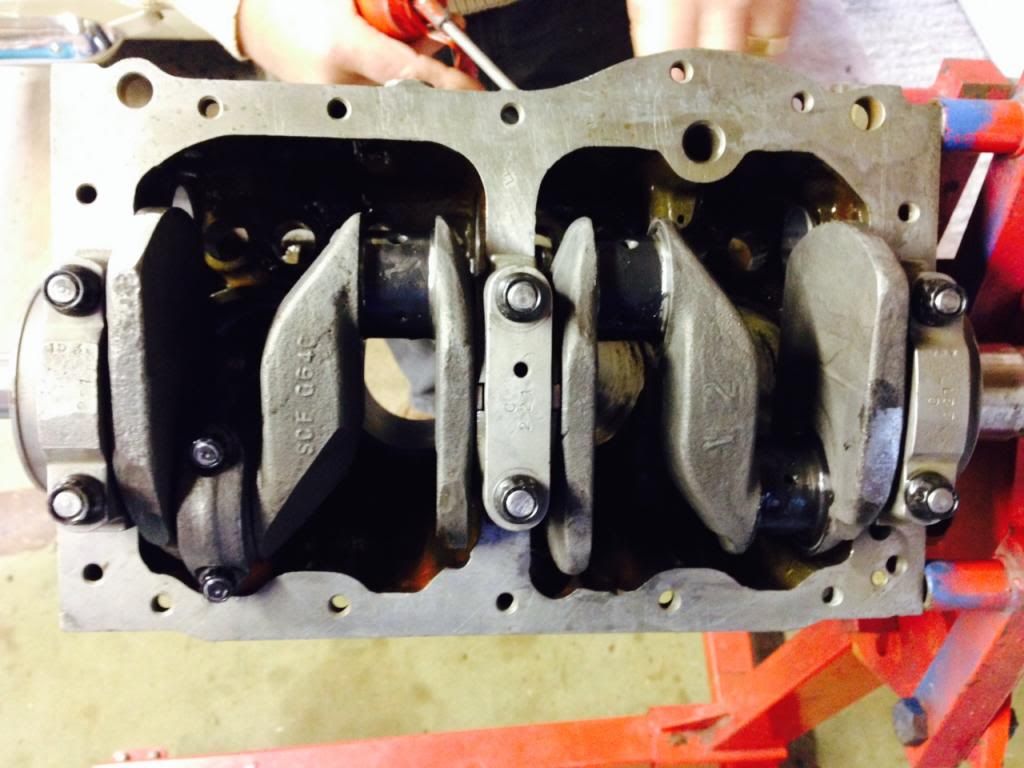

Torque the stud nuts on mains to 57 lb.ft. but don't use Loctite or lubricant ( I always use 60 lb.ft. and it seems fine).

Torque the big-end nuts to the figure in the manual if using standard studs/nuts or to ARP setting if using ARP stuff (which is top quality).

Good idea to use Loctite to secure the oil gallery plugs.

Graphogen will be fine for lubricating the cam lobes. It is just to prevent scuffing at initial start-up. Once the oil has really got round the cam lubrication is not a problem.

Don't neglect to do a 'trial build' before final assembly in order to check the engine goes together properly and to check all the dimensions, for example that the pistons come right to the tops of the bores and that the ring gaps are between 0.008" and 0.015" for all rings.

It sounds like a great specification so good luck with the build.

#3

Posted 18 December 2013 - 11:26 PM

sounds like a real peach of a build.......nice....... ![]()

#4

Posted 19 December 2013 - 10:26 PM

Torque the stud nuts on mains to 57 lb.ft. but don't use Loctite or lubricant ( I always use 60 lb.ft. and it seems fine).

Torque the big-end nuts to the figure in the manual if using standard studs/nuts or to ARP setting if using ARP stuff (which is top quality).

Good idea to use Loctite to secure the oil gallery plugs.

Graphogen will be fine for lubricating the cam lobes. It is just to prevent scuffing at initial start-up. Once the oil has really got round the cam lubrication is not a problem.

Don't neglect to do a 'trial build' before final assembly in order to check the engine goes together properly and to check all the dimensions, for example that the pistons come right to the tops of the bores and that the ring gaps are between 0.008" and 0.015" for all rings.

It sounds like a great specification so good luck with the build.

Thank you cooperman. All the rings where between 14 and 16 thou. Piston height is good.

#5

Posted 19 December 2013 - 10:37 PM

#6

Posted 19 December 2013 - 10:47 PM

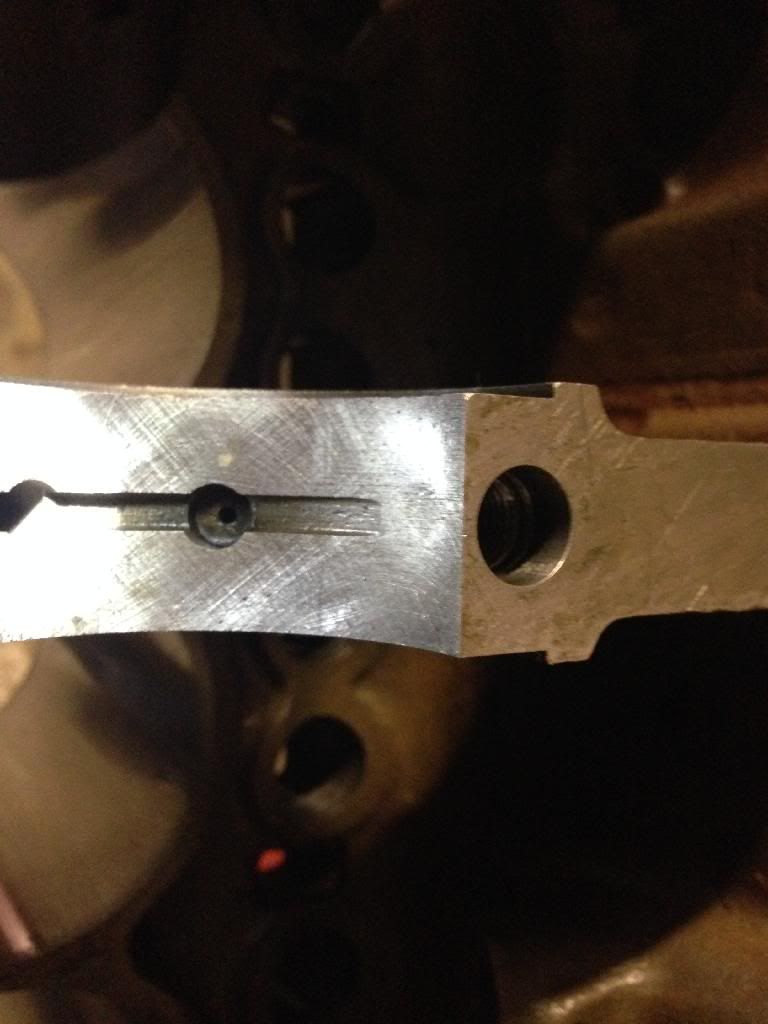

Yes, you do need a minimum of around 0.002" cam end float when it's all bolted up. The cam retaining plate will have some rotational marks, but should not be scored. Lightly linish the plate on the inside face, i.e. the one against the block, if necessary to achieve this float.

#7

Posted 20 December 2013 - 10:06 PM

Thanks Dave

#8

Posted 20 December 2013 - 10:46 PM

#9

Posted 21 December 2013 - 10:53 AM

Did you skim it off the back face and not the bearing face?

The cam gear side

#10

Posted 21 December 2013 - 01:48 PM

I don't remember which side... but one side of that plate has bearing material on it as GraemeC Mentioned.

The plate is going to get wear marks on it. Too late now... but I would not touch it unless the endfloat clearance is too small/tight when the plate is bolted to the engine block.

#11

Posted 12 January 2014 - 07:14 PM

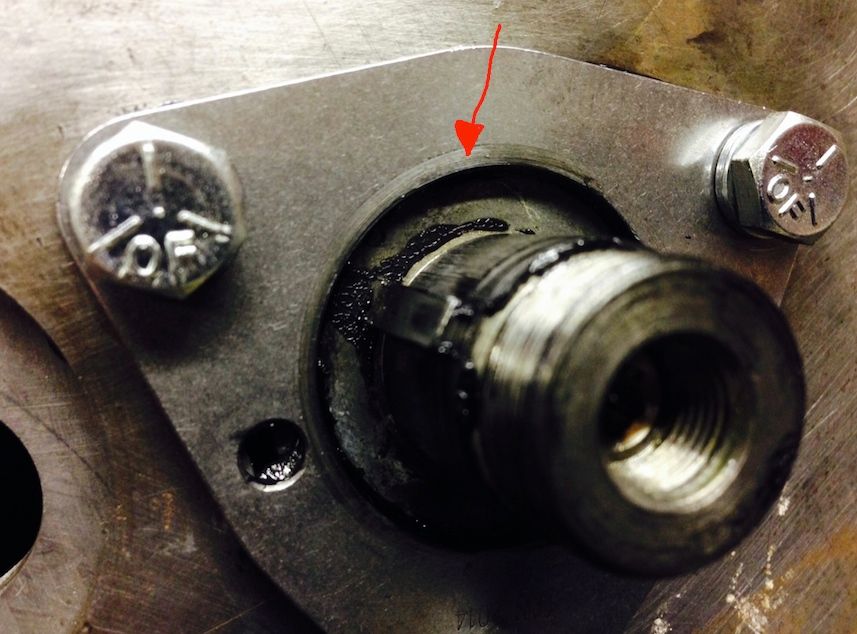

Got these for my S block, think they are the right ones for the age and spec...... but

do I need to use cork or rubber seals with these? Im not sure of the exact date of these ones.

http://www.minispare...|Back to search

http://www.minispare...39.aspx|Back to

Thanks Dave

Edited by dgear1984, 12 January 2014 - 07:15 PM.

#12

Posted 12 January 2014 - 07:37 PM

The red rubber seals are best and are what everyone with an 'S' who I know uses.

#13

Posted 13 January 2014 - 12:38 AM

+1 on the rubber seals.

#14

Posted 22 January 2014 - 10:06 PM

Been reading up on running in procedures. What is the reasoning behind running the engine up the first time until the head is warm to touch with no water in it.

Must admit, never really done much with engines, normally they have always come from the engine tuners built, dyno'd and ready to go, just fit and crank for oil pressure, brum.......

#15

Posted 23 January 2014 - 12:19 AM

I have only heard the recommendation for the dry start when using a black Payen gasket. I was told that it helps the sealant on the Payen gasket soften and stick to the block and head. I have not heard of anyone doing the dry start with other head gaskets.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users