Hi all,

Around sort of July time last year was on my way to pick my girlfriend up to take her to the cinema car seemed to be ok, pulled up at her house got out went to get her, got back to the car fired the car up, just pulling out of the car park near her house noticed the steering seemed to be feeling funny, it had felt ok on the way there but a few days previous id noticed few odd things, but all of a sudden on after leaving it went really stiff, but not stiff through out the lock only in places, got down the road an I said were gonna have to go back its not safe to go out in this plus we needed to go down the motorway, so we went back and go her mini.

Left mine over night, decided to go to work in it the next day which is just down the road was thinking maybe a steering component was knackered or even if the rack was damaged excessive play somewhere etc.

Anyway took the car off the road and spent ages trying stuff an I couldn't fully explain to people what it exactly was doing, until one day someone said, 'have you thought it could be the diff?' maybe im silly for not thinking it but the Diff never even entered my mind but it can effect steering, now when this person had said this id actually took the car out to go see them at there house cause we'd all just been to a local car show and I nipped back home to fetch my car to show them, when I got there oil was pouring out the gearbox not pouring but alot of it dripping out, jacked the car up ran it in gear an there was a terrible noise coming from the diff so thats what it was, so got the car over the pit at my grandads garage one Saturday and started to take the engine out, was abit nervous as Ive not done this before and MPI engine bay has alot of stuff in it haha.

Luckily I had built a gearbox before so id hoped the damage wouldn't be too bad

IMG-20130823-02109.jpg 73.68K

4 downloads

IMG-20130823-02109.jpg 73.68K

4 downloads

IMG-20130824-02111.jpg 87.08K

4 downloads

IMG-20130824-02111.jpg 87.08K

4 downloads

IMG-20130824-02112.jpg 77.04K

3 downloads

IMG-20130824-02112.jpg 77.04K

3 downloads

IMG-20130824-02113.jpg 77.83K

3 downloads

IMG-20130824-02113.jpg 77.83K

3 downloads

IMG-20130825-02115.jpg 91.29K

0 downloads

IMG-20130825-02115.jpg 91.29K

0 downloads

Had a look when I got it back to my workshop this showed something had certainly gone wrong in there

IMG-20130825-02116.jpg 47.25K

13 downloads

IMG-20130825-02116.jpg 47.25K

13 downloads

Scoring around the Diff cage and cracked cover, found bits of planet gear in the bottom

IMG-20130826-02120.jpg 50.25K

9 downloads

IMG-20130826-02120.jpg 50.25K

9 downloads

Damage to the machined face where to cover fits up

IMG-20130826-02123.jpg 60.79K

10 downloads

IMG-20130826-02123.jpg 60.79K

10 downloads

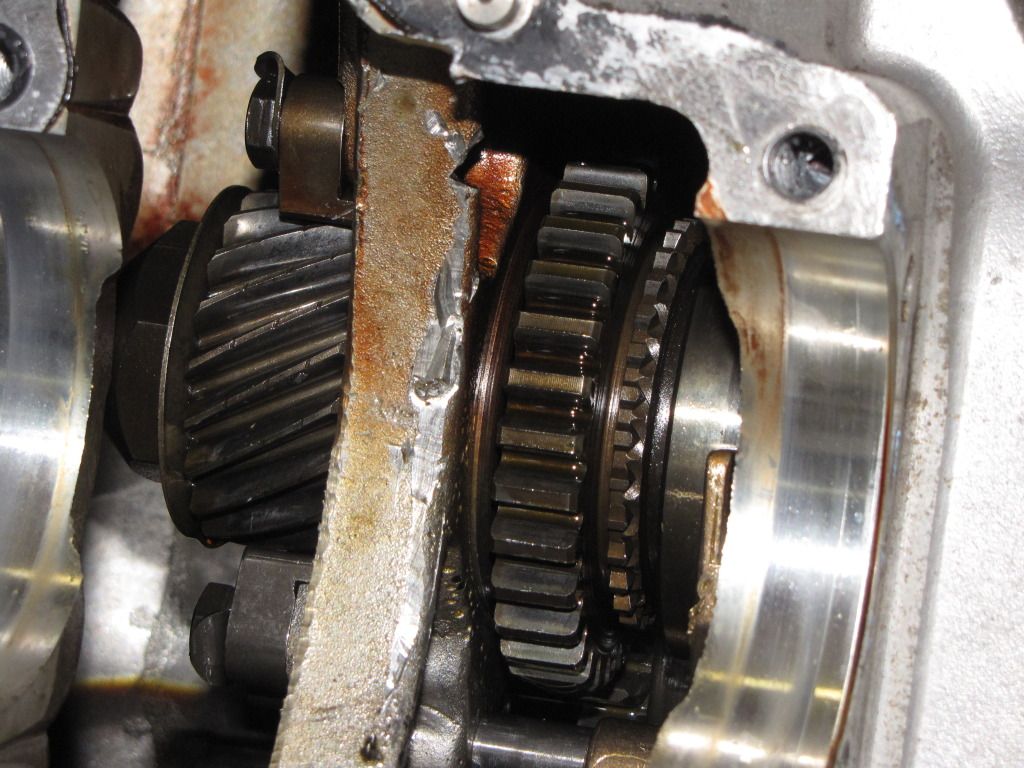

Started the strip down, hoping there wasn't too much damage

IMG-20130827-02137.jpg 71.13K

3 downloads

IMG-20130827-02137.jpg 71.13K

3 downloads

IMG-20130828-02138.jpg 43.78K

1 downloads

IMG-20130828-02138.jpg 43.78K

1 downloads

Sat the engine onto an old remote box I got for the time being so I could sort the gearbox

IMG-20130828-02140.jpg 84.15K

0 downloads

IMG-20130828-02140.jpg 84.15K

0 downloads

Got the box on the workbench ready to strip

IMG-20130828-02141.jpg 79.08K

4 downloads

IMG-20130828-02141.jpg 79.08K

4 downloads

Bit of planet gear that was stuck to the sump plug magnet, (did its job well)

IMG-20130828-02142.jpg 72.24K

14 downloads

IMG-20130828-02142.jpg 72.24K

14 downloads

Also found this in the bottom of the gearbox when I first took the diff off

IMG-20130826-02118.jpg 50.87K

4 downloads

IMG-20130826-02118.jpg 50.87K

4 downloads

Box stripped

IMG-20130828-02144.jpg 78.3K

6 downloads

IMG-20130828-02144.jpg 78.3K

6 downloads

Like to start off with a clean bench and bins labelled up so nothing gets lost, had to keep it that way though haha

IMG-20130828-02145.jpg 73.06K

2 downloads

IMG-20130828-02145.jpg 73.06K

2 downloads

So I inspected the casing, and the damage was, a dent into when the diff cover fits up the gasket face as shown in the picture, and what the most worrying for me was a crack where the planet gear had been fired into the central webbing that holds the 3rd motion bearing.

I'm pretty stubborn and I wanted to save the gearbox and keep most of it original to the engine so I vee'd out the crack and took it to a place the had an aluminium welder, it was aluminium MIG.

The weld ended up being abit lumpy and built up quite alot but it did fill in the crack id vee'd out

the guy did it for free too

IMG-20130831-02152.jpg 40.71K

7 downloads

IMG-20130831-02152.jpg 40.71K

7 downloads

Because the weld had built up alot I couldn't completely see if all the crack was filled in om either side of the webbing and it looked abit messy so I took it back and sat out side at a table nd spent an hour or so with the dremal grinding it back to shape to see that it had done its job.

It was tricky getting in the with the dremal so I couldn't get it completely smooth but it was roughly the right shape, I never got any photo's of the weld before

IMG-20130831-02154.jpg 75.03K

17 downloads

IMG-20130831-02154.jpg 75.03K

17 downloads

IMG-20130831-02157.jpg 82.49K

9 downloads

IMG-20130831-02157.jpg 82.49K

9 downloads

Took it to work the next day and got the die-pen spray on it, didn't show anything up so was pleased

IMG-20130831-02158.jpg 73.82K

11 downloads

IMG-20130831-02158.jpg 73.82K

11 downloads

Part of my job involves Beed Blasting so it comes in handy now and again with parts I once did a casing in there for a friend who's gearbox I rebuilt, so decided to do my own.

I'm quite pedantic with some things so I made a set of nylon bungs that fit into the bearing housings to stop the glass beed wearing the machined faces away during blasting as they are part of the precision and form the interference fit of the bearings also.

This isnt the same gearbox, I only have pictures of the one from my car after it was done

beeed.jpg 43.65K

6 downloads

beeed.jpg 43.65K

6 downloads

420775_457309251018127_1627131233_n.jpg 43.22K

5 downloads

420775_457309251018127_1627131233_n.jpg 43.22K

5 downloads

551432_457309194351466_2086253886_n.jpg 35.66K

4 downloads

551432_457309194351466_2086253886_n.jpg 35.66K

4 downloads

562387_457309161018136_2028009278_n.jpg 39.46K

5 downloads

562387_457309161018136_2028009278_n.jpg 39.46K

5 downloads

This is the one from my car the only picture I got after it came out the cabinet

IMG-20130902-02165.jpg 62.67K

7 downloads

IMG-20130902-02165.jpg 62.67K

7 downloads

Degreased/oiled all the parts and set off putting it back together with new parts where needed such as the usual musts like main bearings and baulk rings etc I reused the needle bearings that the gears spin on, put new layshaft bearings in though and idler bearing

IMG-20130903-02169.jpg 84.78K

8 downloads

IMG-20130903-02169.jpg 84.78K

8 downloads

Main shaft back together

IMG-20130905-02178.jpg 73.72K

4 downloads

IMG-20130905-02178.jpg 73.72K

4 downloads

IMG-20130911-02186.jpg 58.86K

5 downloads

IMG-20130911-02186.jpg 58.86K

5 downloads

IMG-20130911-02188.jpg 59.71K

2 downloads

IMG-20130911-02188.jpg 59.71K

2 downloads

IMG-20130911-02190.jpg 69.64K

6 downloads

IMG-20130911-02190.jpg 69.64K

6 downloads

IMG-20130912-02200.jpg 73.47K

2 downloads

IMG-20130912-02200.jpg 73.47K

2 downloads

IMG-20130912-02201.jpg 78.03K

1 downloads

IMG-20130912-02201.jpg 78.03K

1 downloads

Once the main gearbox was built I started to clean up the other parts

IMG-20130912-02192.jpg 55.88K

1 downloads

IMG-20130912-02192.jpg 55.88K

1 downloads

IMG-20130912-02193.jpg 51.42K

0 downloads

IMG-20130912-02193.jpg 51.42K

0 downloads

I decided to clear Lacquer all the aluminium stuff to try to at least keep it looking like it did when it was blasted so I masked of the bits I didnt want to get any overspray into

IMG-20130912-02196.jpg 69.53K

2 downloads

IMG-20130912-02196.jpg 69.53K

2 downloads

IMG-20130912-02197.jpg 77.37K

3 downloads

IMG-20130912-02197.jpg 77.37K

3 downloads

IMG-20130913-02202.jpg 61.75K

0 downloads

IMG-20130913-02202.jpg 61.75K

0 downloads

IMG-20130917-02207.jpg 52.69K

1 downloads

IMG-20130917-02207.jpg 52.69K

1 downloads

Chose not to do this until id built it gave it a few coats of clear lacquer

IMG-20130919-02211.jpg 77.53K

3 downloads

IMG-20130919-02211.jpg 77.53K

3 downloads

Edited by Jake Didsbury, 04 January 2014 - 12:46 PM.