For my college project, Stiggytoo and I have been studying into the difference between cylinder head castings and what can be modified to achieve better air flow into the head.

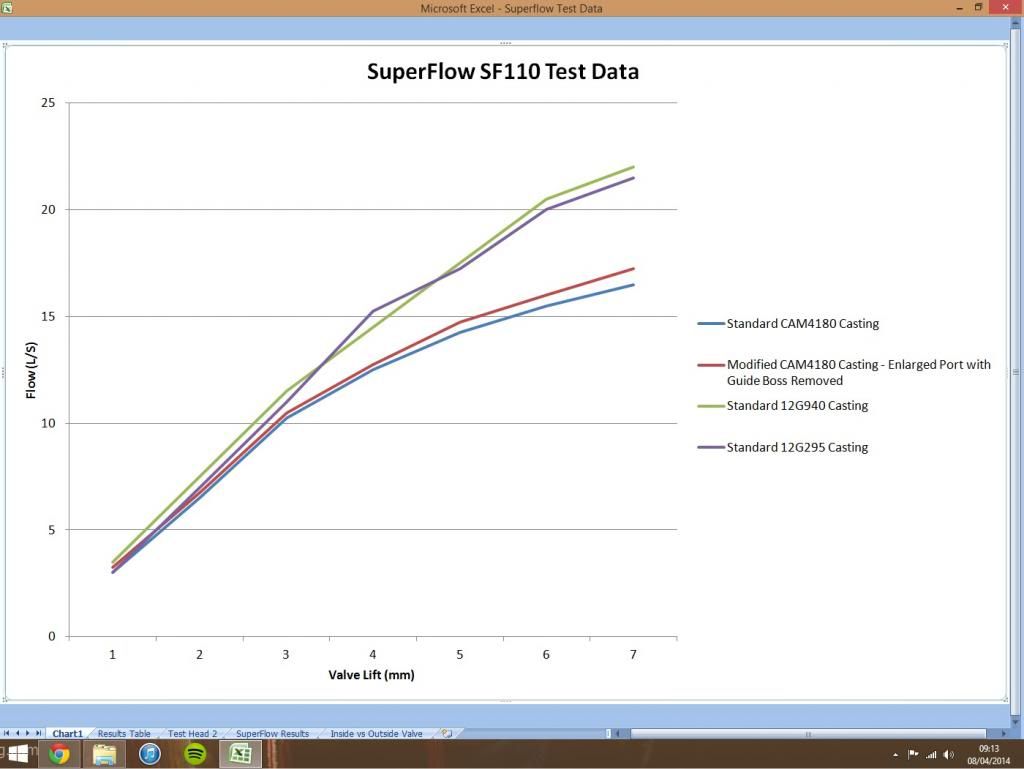

First of all, we flow tested 3 different head castings which included a standard 998 head (CAM4180), a standard 1275 head (12G940) and a standard 12G295 head. We also tested our modified CAM4180 casting which we enlarged the inlet port slightly and ground away the valve guide boss and smoothed it all out.

All of our tests were carried out with a standard twin carb manifold, the reason being will become clear later on...

And the results were in:

There is a clear difference between the CAM4180 head and the other two heads we tested. However with out slight modifications, we made a small improvement on the CAM4180 head across all valve lift, a result for us.

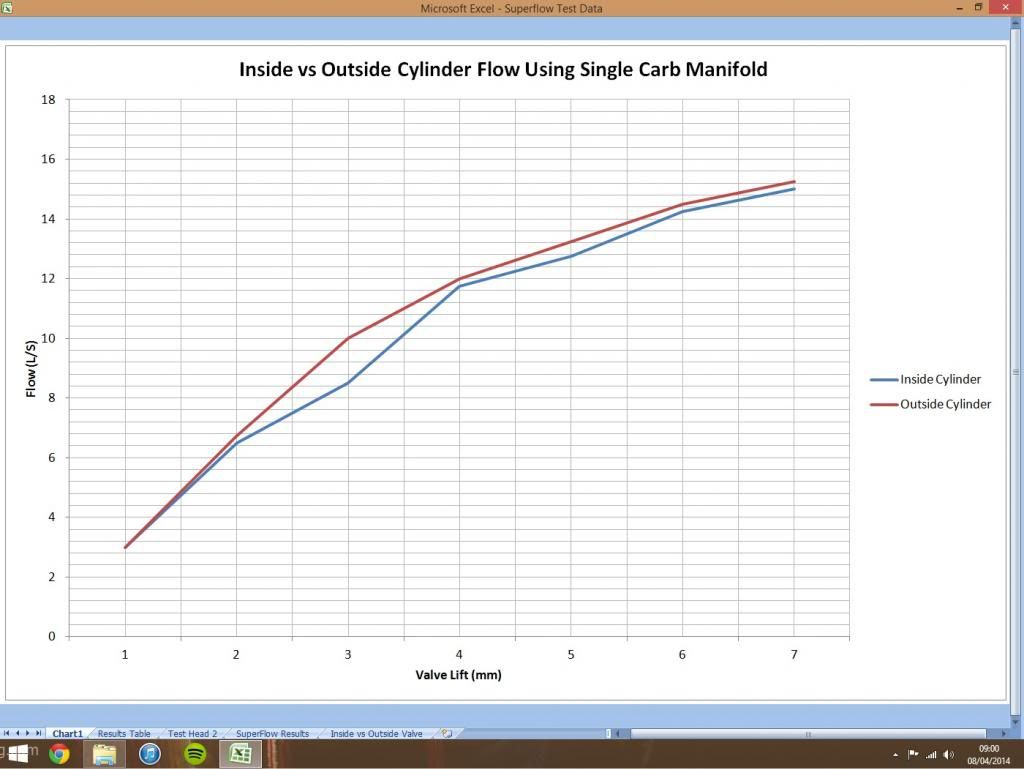

Now as we also found out, when using a standard single carb metro manifold, the outside port is biased hugely throughout the valve lift as show here:

When we performed the same test with a standard twin carb manifold, the values were pretty much the same. However, we do not have a graph for this test unfortunately.

I hope our results are helpful to anybody as they show how restrictive the standard 998 head is compared to say a 1275 head