Well, I should kick off by say this is not for me! This is actually the repair of a Gearbox for a Moke known as Quadra. suffered a major failure at an outing a few years back now. I undertook this re-design / repair back in early 2012.

It was originally made by a guy in our club, Max Kinsmore, back in the late 70's. The Bevel Gears used in this one are actually from a Prototype that was Made by our local Leyland Factory as they were considering putting these in to production - another story for another time! I digress - This Leyland Prototype design is actually based upon the Leyland ST Mini, which in turn was based on one of Issigonis's Prototype Single Engine, 4WD Mokes of the early 60's.

A Friend of mine now owns the Moke, which is not a factory car, but does have a few factory parts in it.

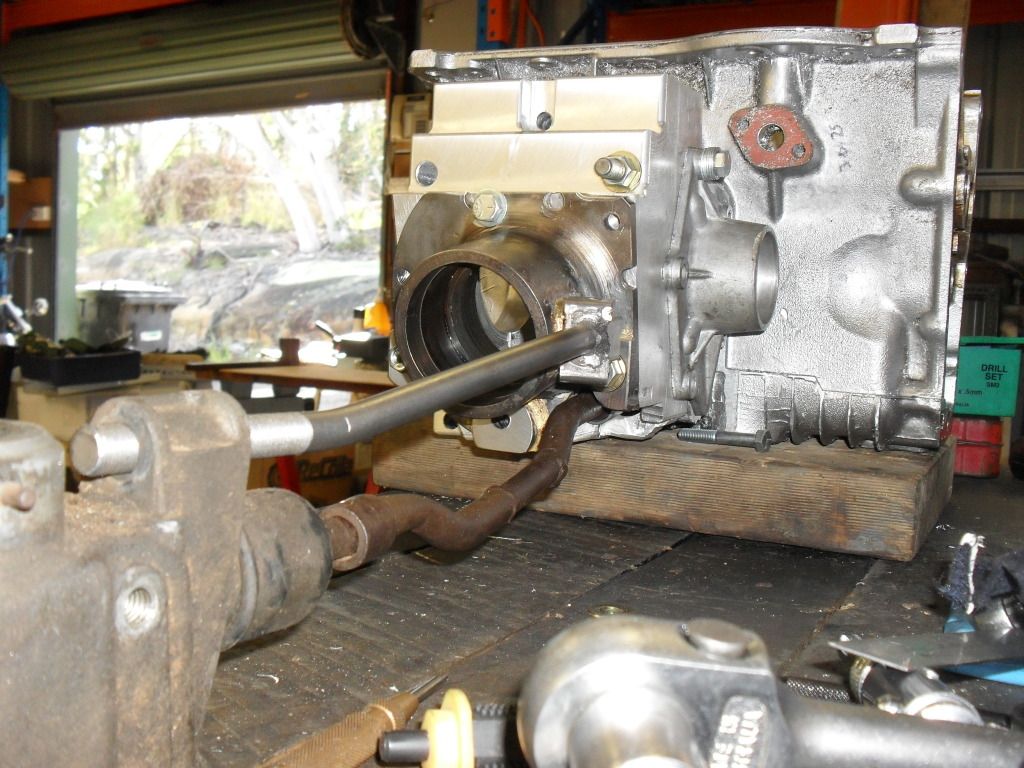

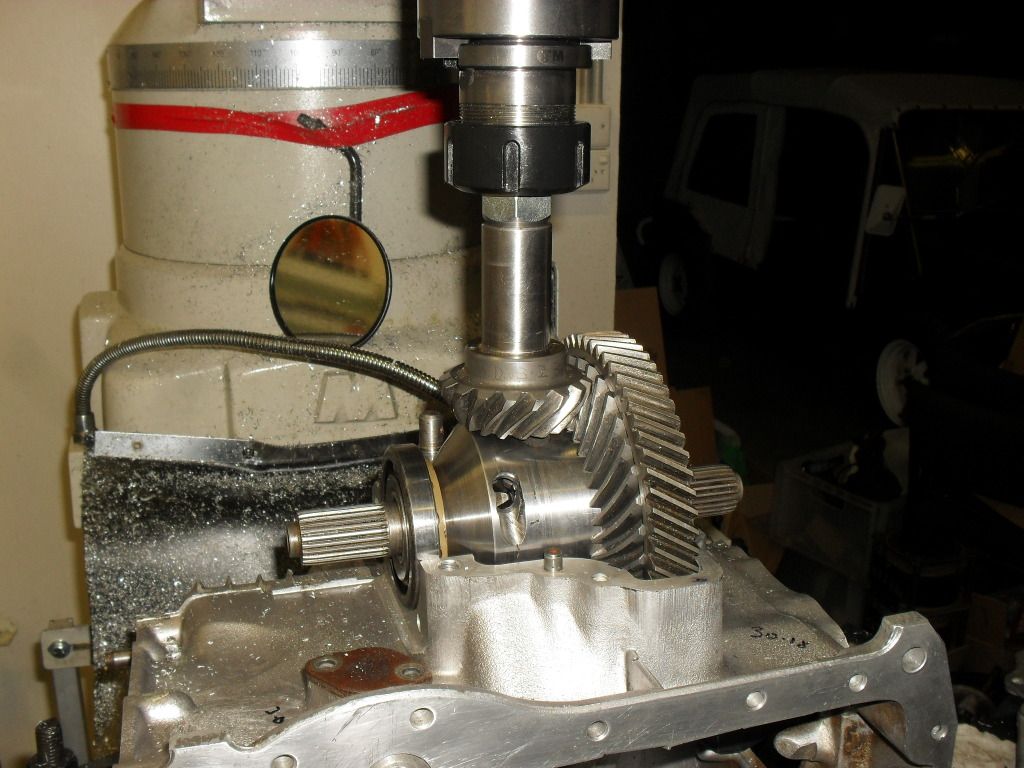

This was the gearcase from it, after I'd stripped most of it

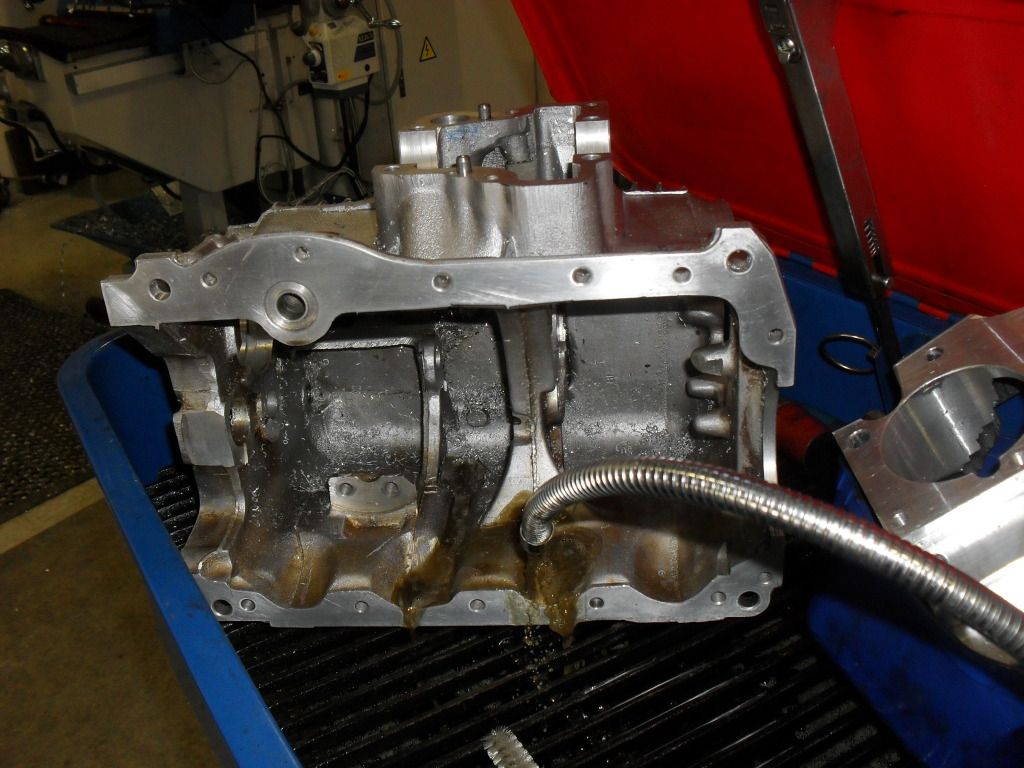

When it was stripped down, the diff pinion was found in a hundred pieces. Not the first one I've seen like this

but closer inspection of the gearcase show a LOT of other problems, most of them old, but signs that this design was not up to the task

the case and the diff cap were fund FULL of cracks and other damage from previous failures. The diff cap hardly even lined up, so no wonder it leaked oil.

It was off to the drawing board for a few weeks. I came up with a solution and design to overcome all it problems and (hopefully!) make it un-breakable.

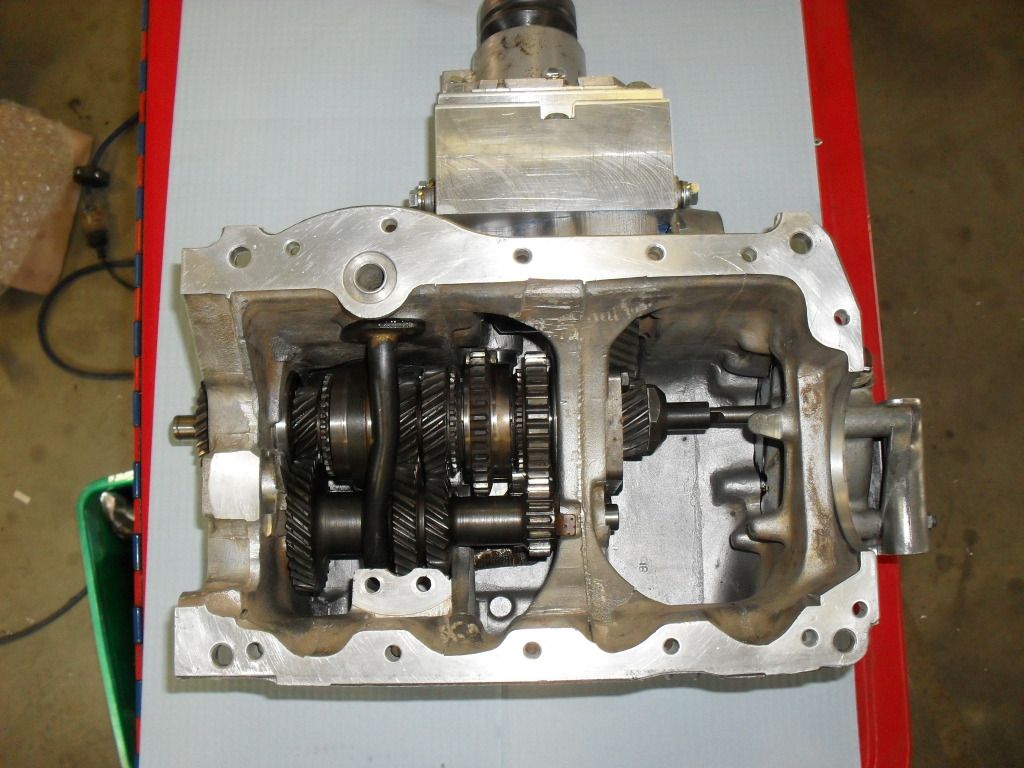

So, next thing was to start making all the bits

First was the diff hemispehere. The stock 2 sun gear designs are hopeless, so I made a 4 sun gear, X-pin type

I had to make a special tool to cut the thrust faces for the sun gears

trial fit to check it's shape - perfect!

now to cut them for real

starting to take shape

next, I had to machine up a crown wheel, this is another weak point in the stock mokes and this one is no exception

then fit the bevel gear to it

then the next major problem part, the diff cap. We got a new gearcase and I had to measure up super-accurately the existing diff cap

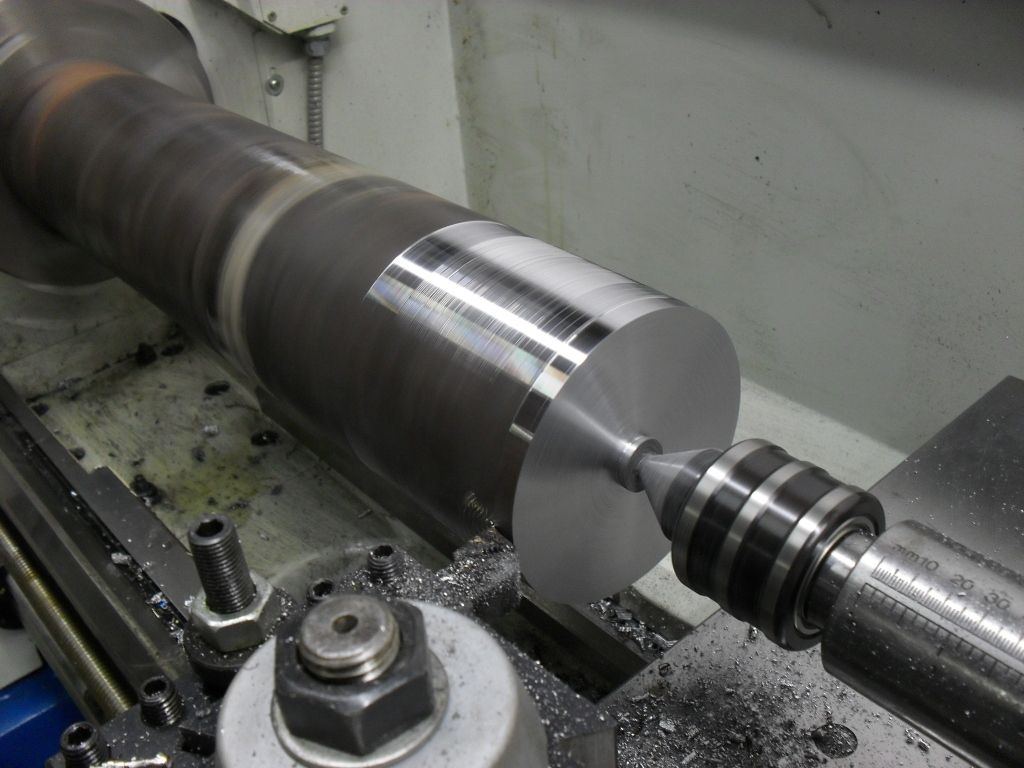

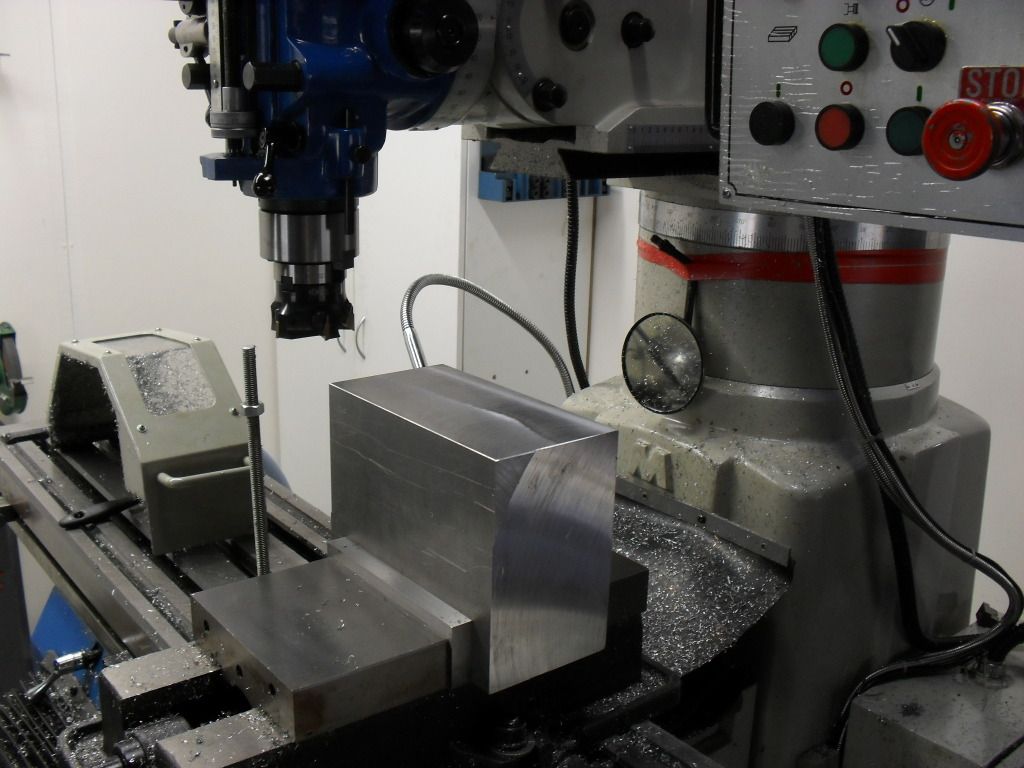

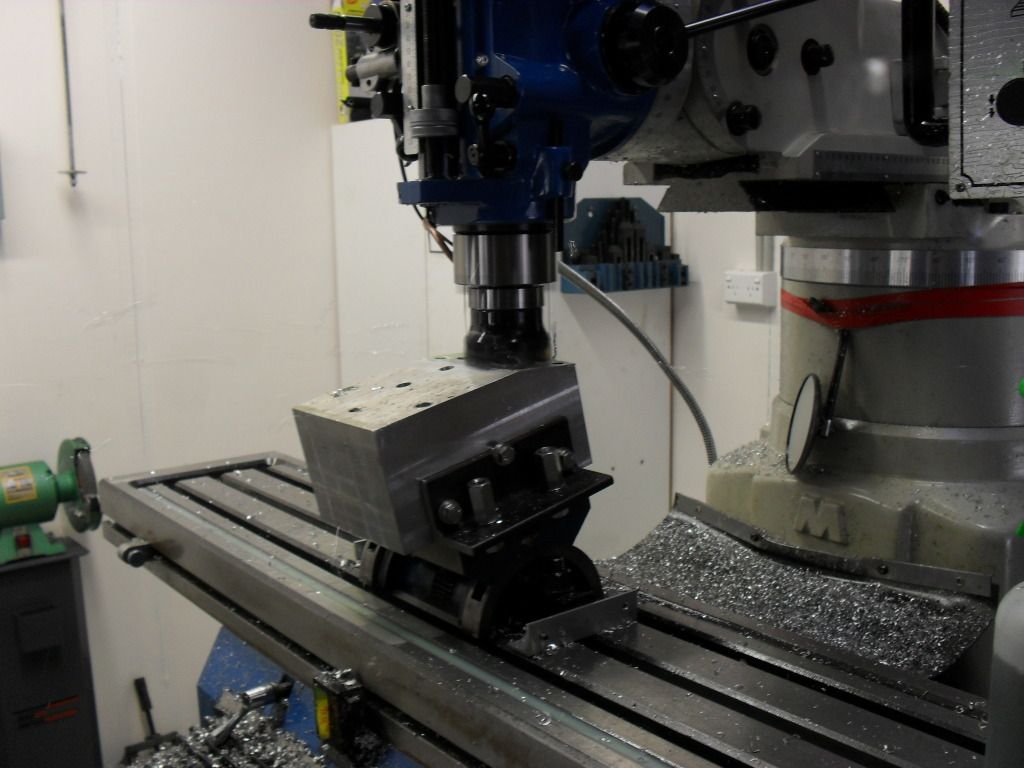

I machined up a new one from a soild billet. Here, I'm just starting to face it, to get it 100% square and flat

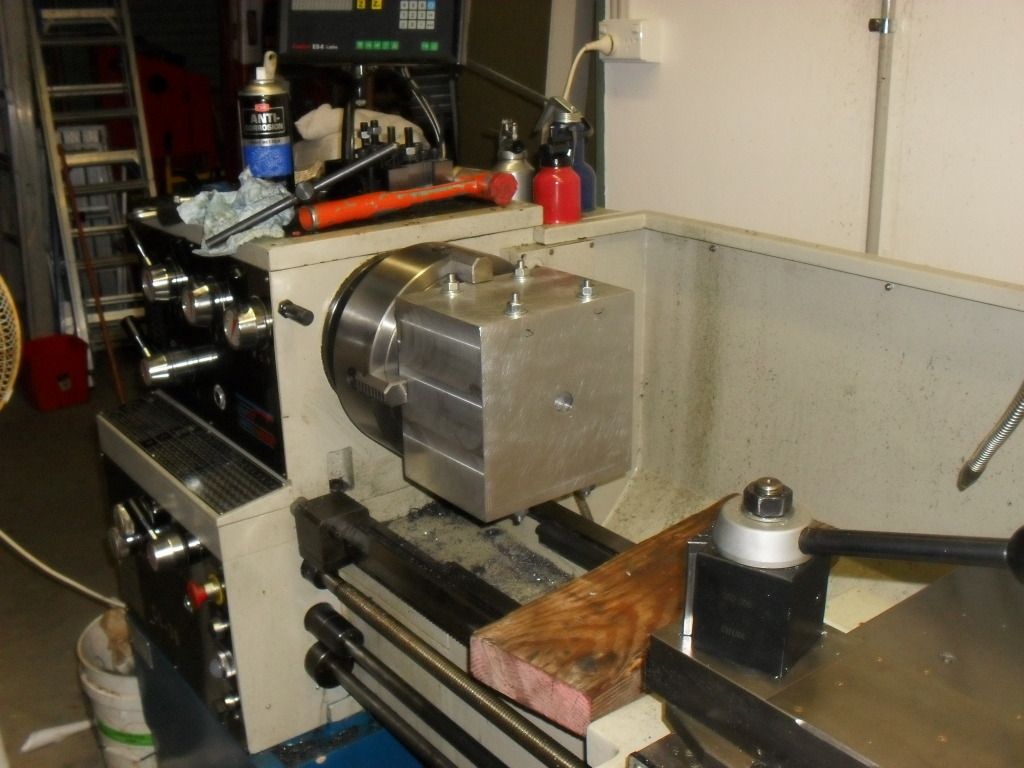

then next was the bearing tunnel. to get this perfectly round and on size, I had to bolt it up to another piece the same. This is the start of something BIG

back in the lathe

boring it

perfect!

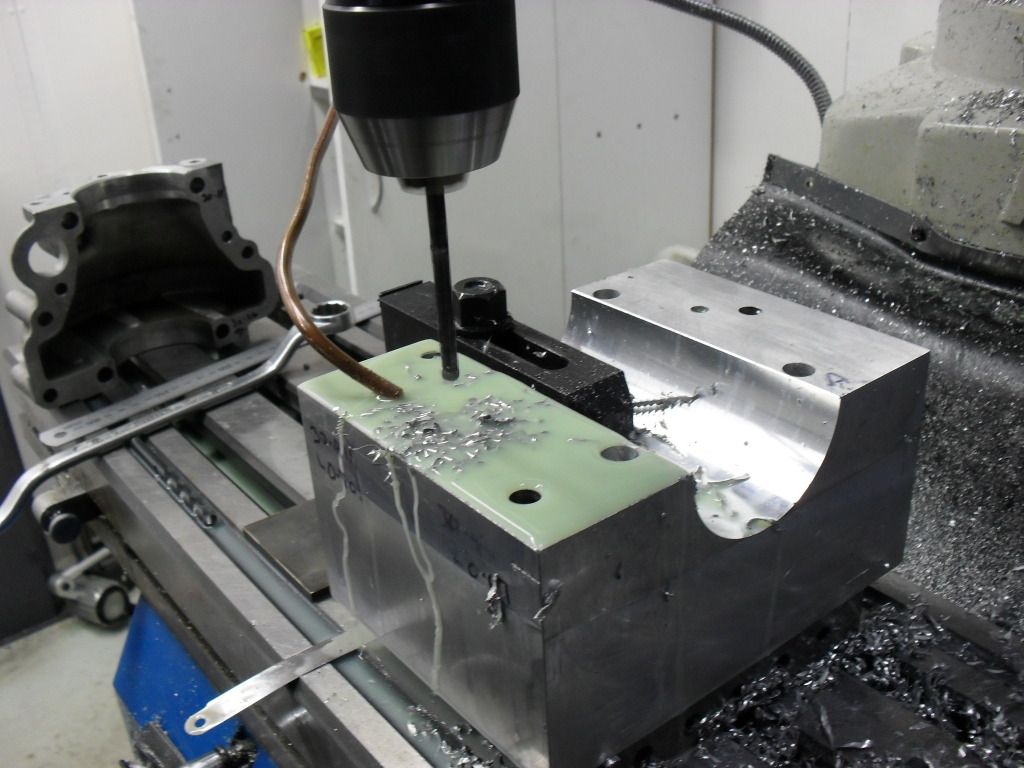

pitch out and drill all the holes. This needed to be super-accurate (I was working to +/- 0.005 mm!)

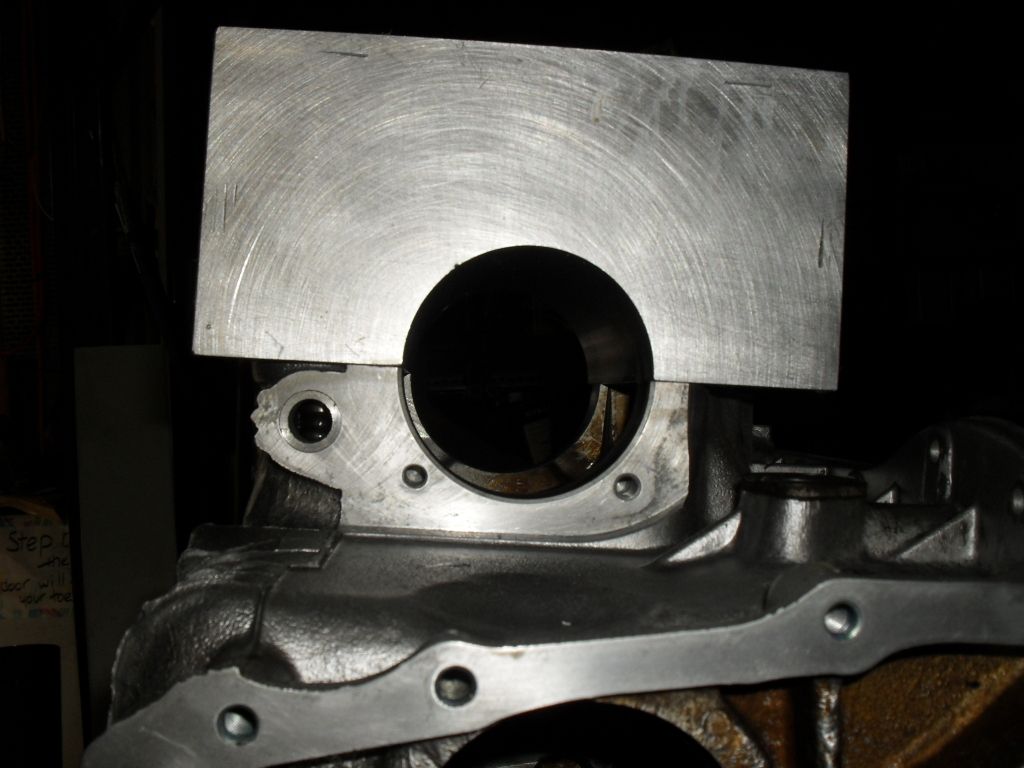

fits and lines up! Bonus!

next, some relieving of the gearcase as the new diff is bigger

trail fitting the diff

yippie!

next, I had to measure exatly where the output pinion needed to be for the RWD part

then, I could machine out the guts of the cap

look it fits!

then face back the cap to get it all lined up with the gearcase

planing the back of the diff cap at an angle, to get the output pinion facing the right way

boring the hole for the pinion

just about there!

there, all major machining done!

all that's left now is the big clean up and assembly!

To be continued.