Looking for someone who can tig alloy needing 4 short pipes put on a micra manifold as local company's to me either aren't interested or want to charge silly money!

If any one can help please message me I'll upload some photos tonight to show what I'm after! Cheers

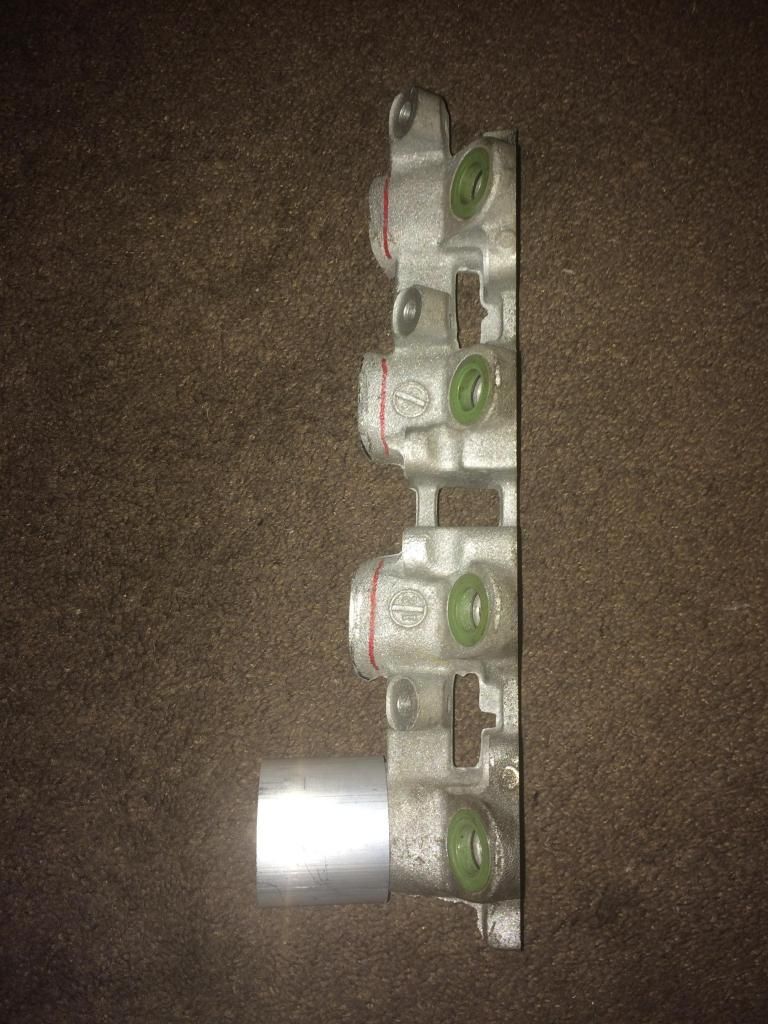

And photos

you can see in photo 2 the difference in size/shape of the piping this is my second choice set up using silicone hoses up to a steel plenum

My first option would preferably be a one piece mani/plenum setup using the original cast mani face/flange whatever you want to call it with enough room for injectors up 90 degree bended alloy into a plenum where i can bolt the original throttle body to the en. I really hope someone makes sense of what i mean ![]()

Edited by StewartB, 10 February 2015 - 08:58 PM.