Yes, just about all pistons are slightly oval.

Not a lot, just so that when at running temperature the piston to bore clearances are optimised.

The bores are all perfectly round, or should be... The only company I can think of who tried out oval bores for a while was Honda on their 500cc V4 racer back in the 80's. They went back to round bores, so I guess this was not a success.

Carbon is on the money here, no question in the world! Where there's more metal, the pistons will expand the most from ambient to running temps.

So, the Crown of the piston is a fair bit smaller as not only is there more metal there, but it's also subject to higher heat than the skirt.

Likewise, the Gudgon Pin Bosses have more metal here so they also expand more than the skirt either side of them, though these days, there is a tend to go to wasted skirts, so it is difficult to pick up that this is the case.

The process for manufacturing the pistons to this shape is refered to as 'Cam Ground' though once they were actually ground to shape and size, these days it's done by CNC.

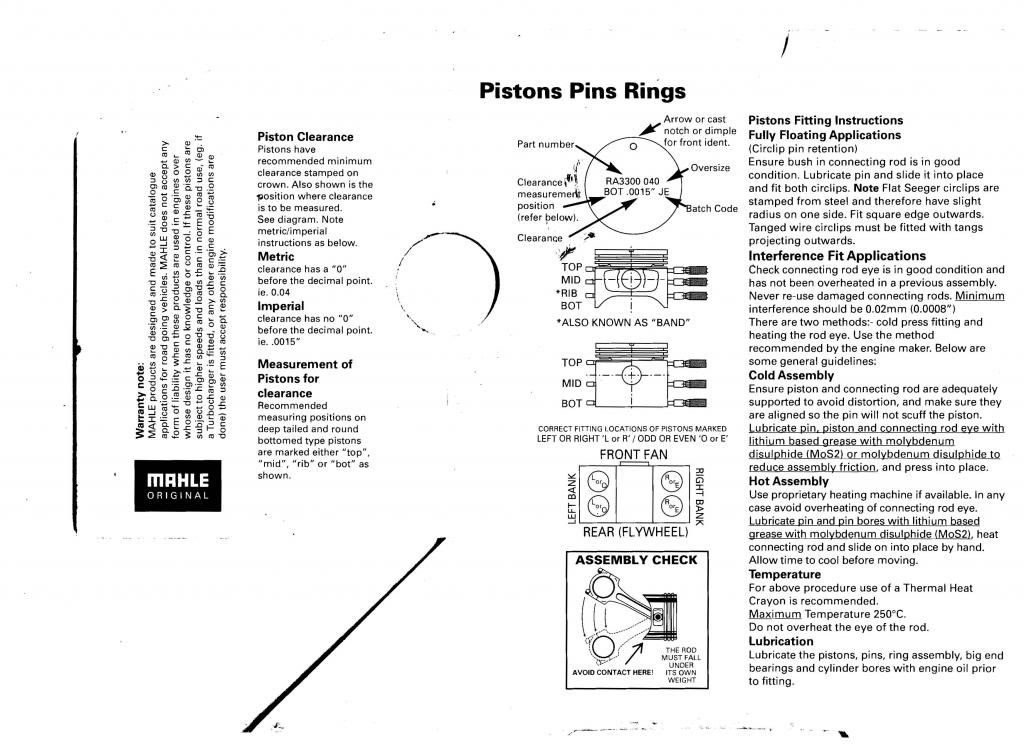

Sometimes too, odd shapes are manufactured in to the piston shape for thrust compensation (thrust ve non-thrust) and this is why some pistons specifically state which way around (ie FRONT or an Arrow) they have to be fitted in to the engine, sometimes these also have off set Pin Bores too. Another reason is for coff coff silent running. An example of this is the early 850 pistons which had a spilt skirt, though I recon it was a governor of sorts.

Edited by Moke Spider, 28 March 2015 - 09:14 PM.