Basically I've got cracking seams all on my front end, I'm intending to repaint her again in the summer but don't want to go through all that to have her start to crack again

Scuttle panel to wing crack

My issue here is that the scuttle to wing seam underneath is seam welded together, I did this back when I restored her to prevent this exact problem from happening. Top of the seam is filled with tigerseal

Off side front wing to seam joint

Again this is fully welded at the rear then seam sealed at the front with a skim of filler to smooth it all off

And nearside front wing to front panel seam

Again same process as the off side joint

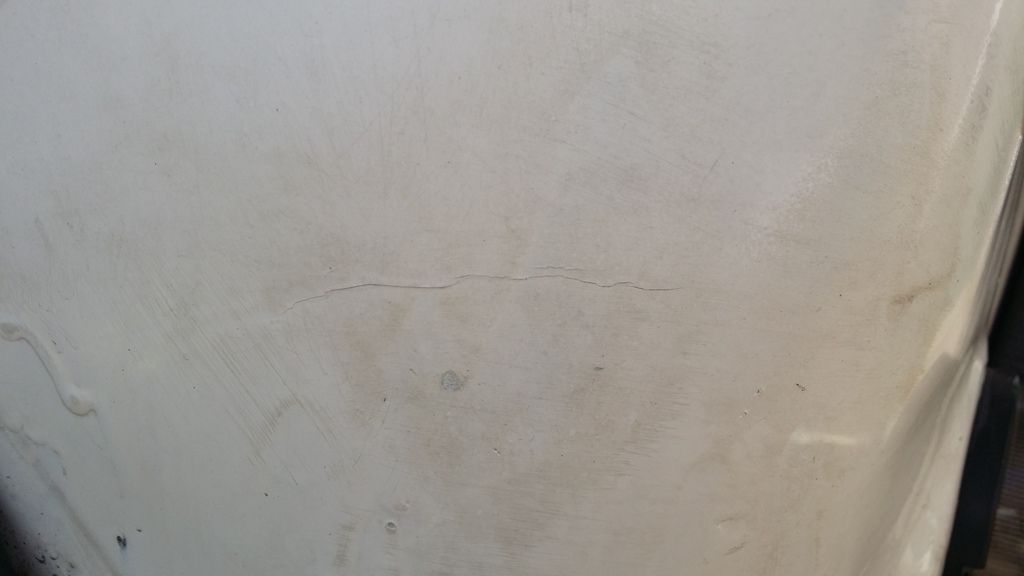

And this is the metal tearing issue I've been having

Hopefully somebody can shed some light on this annoying situation!

Many thanks

Lawrence