Pre Verto Clutch Spacers

#1

Posted 06 February 2016 - 07:48 PM

Thanks

#2

Posted 06 February 2016 - 08:14 PM

Height of the spacers does vary slightly according to flywheel, backplate, and clutch plate. The correct height of spacer will set the driving straps parallel to the flywheel face.

If you do a dummy build of the flywheel assembly with backplate, clutch plate and driving straps you can either use a stack of washers or measure up to find the best spacer height

#3

Posted 06 February 2016 - 08:31 PM

Height of the spacers does vary slightly according to flywheel, backplate, and clutch plate. The correct height of spacer will set the driving straps parallel to the flywheel face.

If you do a dummy build of the flywheel assembly with backplate, clutch plate and driving straps you can either use a stack of washers or measure up to find the best spacer height

Yeap, bang on.

I'll just add that before making the spaces to check and set the height of the posts on the backing plate first. Assemble the flywheel, clutch plate, diaphragm and backing plate and check the bevel spring on the diaphragm is slightly toggled over (past flat) by 0.010 to 0.015" (this is to allow for plate wear), this is adjusted by removing material from the posts or from the faces, depending on which way you need to go.

#4

Posted 06 February 2016 - 09:21 PM

I used these instructions when setting my clutch up: works well :)

Before fitting the Mini Spares Ultra-light steel flywheel, carefully examine the crankshaft taper for any burrs or other protrusions caused by fret-welding of previous flywheels. All protrusions of any sort must be removed as they will cause incorrect seating of the flywheel which could, in turn, cause this fret-welding to occur and permanently damage both crankshaft and flywheel. A recognised method of ensuring correct fit is to use fine valve lapping paste to lap the flywheel on to the taper. A good, correct fit will be confirmed by seeing an even grey finish over the whole of the taper on both components.

The paste should then be thoroughly washed off using a strong cleaning solvent (such as cellulose thinners or brake cleaner). As the flywheel is of a much thinner section than the standard one, distance pieces (spacers) are provided to re-align the clutch drive straps. However it is very strongly advised the following method is used to establish correct alignment: If the pressure plate clutch plate friction face needs re-surfacing, get it machined to clean it up. Make sure the engineering company doing the job records the amount taken off as once done, the recorded amount needs removing from the tops of the 'horns' that stick up to ensure proper clamping force is achieved. If this is not done, clutch slip is inevitable. If using a pressure plate of unknown history, it is IMPERATIVE the clutch drive straps are set at the correct height. Many get this wrong and end up with a slipping clutch for some seemingly unfathomable reason. The following should also be carried out if the flywheel has been machined, or of unknown history also: - Place the pressure plate 'horns' upper-most on something to hold it off of the work surface but not interfere with clutch plate of flywheel - Place the clutch plate in position, with the protruding primary gear spline boss on the underside facing the work surface - Place the flywheel in position - If the drive straps are holding the flywheel up, or are under tension pressing on the pressure plate 'horns', more spacer-washers/shims are needed between the drive straps and flywheel - If there's a gap between the drive straps and pressure plate horns, the spacing between the straps and flywheel needs reducing - If no drive straps are fitted, using a straight edge or drive strap fitted to one of the horns, measure the existing gap between flywheel surface and underside of straight edge/strap, and make suitable spacers to this measurement - Where extra drive straps are fitted, as in racing (3 on each location instead of the original two), it is essential to machine the thickness of the drive strap off of each pressure plate 'horn' and spacer to re-gain correct diaphragm clamping action to avoid clutch slip The idea is to set the straps so that when they are in their 'as assembled' position, they are not under tension, nor are well clear of the pressure plate horns. They should be JUST touching. Under tension the clutch will slip due to decreased clamping pressure. Too far clear may cause disengagement problems.

I got these from MiniSpares on-line shop by searching for this flywheel, and finding the fitting instructions for it .

C-AEG619 Uiltra-light steel flywheel (inertia starter type) fitting instructions

Admin

03/12/2005 11:24:00

Edited by Leonrjohnson, 06 February 2016 - 09:26 PM.

#5

Posted 06 February 2016 - 10:29 PM

#6

Posted 06 February 2016 - 11:27 PM

The diaphragm is the thing that clamps the clutch plate to the flywheel. Once you tighten the diaphragm you will see how it works. But make sure you have the spacers set up as per the instructions before fitting it all together.

#7

Posted 07 February 2016 - 02:22 PM

#8

Posted 07 February 2016 - 07:33 PM

I only did one yesterday.

Sorry, but sounds like you may have done your initial assembly incorrect.

Even before setting the back plate spacers, unless they are crazy long (and I can't say I've ever found that) you shouldn't be able to spin the plate.

Standby, I'll get a pic up.

#9

Posted 07 February 2016 - 07:36 PM

I only did one yesterday.

Sorry, but sounds like you may have done your initial assembly incorrect.

Even before setting the back plate spacers, unless they are crazy long (and I can't say I've ever found that) you shouldn't be able to spin the plate.

Standby, I'll get a pic up.

Exactly as the spring is bolted directly to the back plate. So the clutch plate is clamped. The spacers are there to make sure the drive plates are are the right angle and the backplate it attached to the flywheel.

#10

Posted 07 February 2016 - 07:38 PM

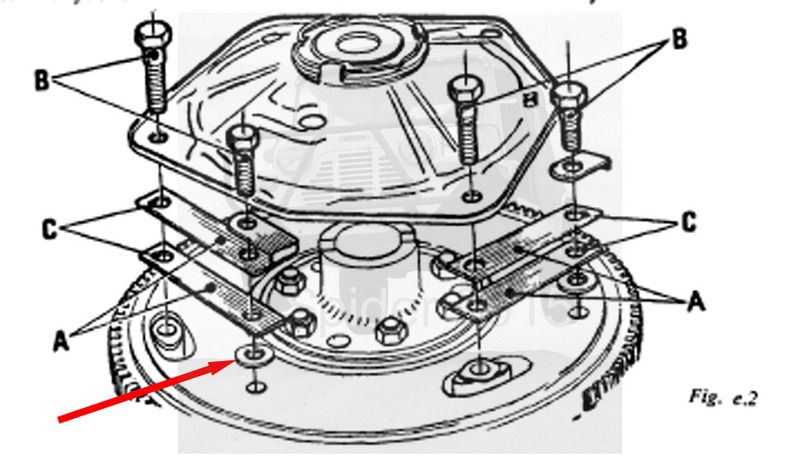

While not a lightened Assembly, it this drawing does show all the parts, except for the spacers, and their correct assembly order.

I put a RED Arrow to a washer which is where the spacers you are asking about will go.

You'll also need to use the same longer bolts that you'd normally use for the backing plate, to go through the Drive Straps, the Spacer that you are making up and in to the Flywheel.

#11

Posted 07 February 2016 - 07:39 PM

#12

Posted 07 February 2016 - 07:44 PM

I see where I've gone wrong now

Nothing like a picture to tell a thousand words.

I guess you were fitting the spacer to the backing plate post?

#13

Posted 07 February 2016 - 07:54 PM

Edited by bluemini1979, 07 February 2016 - 07:55 PM.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users