Hi all.

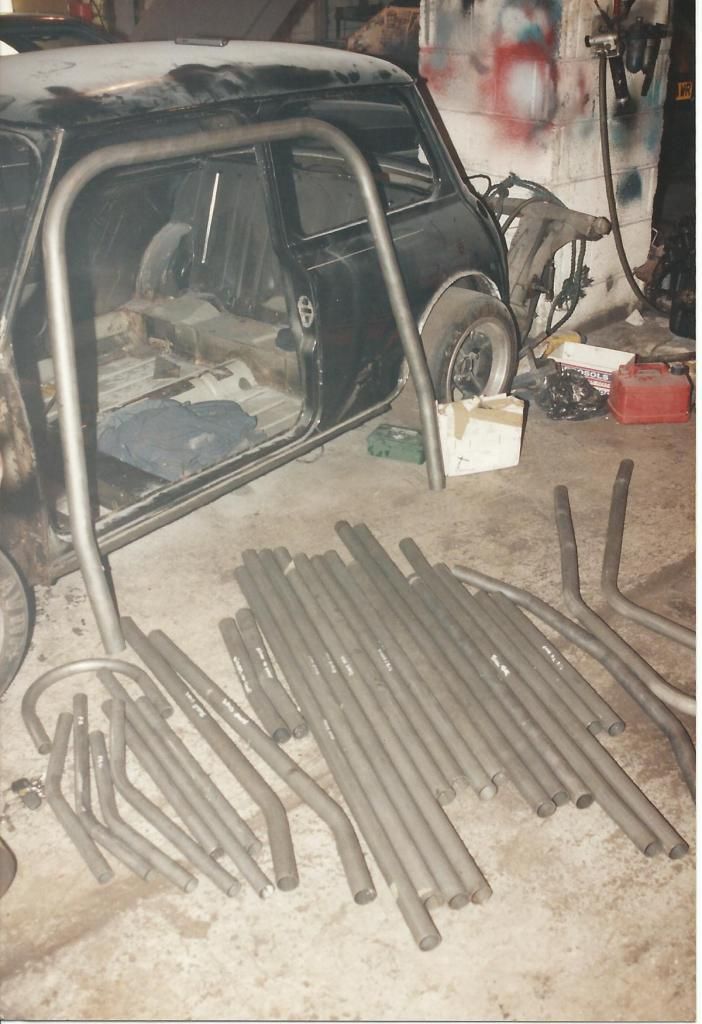

I have searched high and low and just want a definitive answer, hopefully by someone who has experience in this subject and using this size tube . I am planning on using 1 5/8" (41.28) cold drawn seamless tube to build a cage for my mini. I plan of using this mini for track days and would one day like to compete in events such as hill climbs and sprints. I don't want to use the wrong tube now and potentially restrict my possibilities in the future.

I have downloaded a copy of the MSA Blue Book 2016 and from what I can gather I am okay to use this size tube for a roll cage.

'Material Specifications

1.4.1. Specifications of the tubes used:

Minimum Material

Cold Drawn Seamless Unalloyed Carbon Steel, containing a maximum of 0.3% of carbon.

Note: For an unalloyed carbon steel the maximum content of additives is 1.7% for manganese and 0.6% for other elements.

Minimum Yield Strength

350 N/mm2

Minimum Dimensions (Ø in mm)

a) Mandatory tubular members

45 x 2.5 (1.75” x 0.095”) or 50 x 2.0 (2.0” x 0.083”).

38 x 2.5 (1.5” x 0.095”) or 40 x 2.0 (1.6” x 0.083”). (For roll cages/bars approved prior to 1.1.95).

b)Optional tubular members

38 x 2.5 (1.5” x 0.095”) or 40 x 2.0 (1.6” x 0.083”).

1.4.2. In selecting the steel, attention must be paid to obtaining good elongation properties and adequate weldability.

1.4.3. The tubing must be bent by a cold working process and the centreline bend radius must be at least three times the tube diameter. If the tubing is ovalised during bending, the ratio of minor to major diameter must be 0.9 or greater.'

Link - http://www.safetydev...e Book 2016.pdf

To some this might seem obvious but I don't want to get caught out, am I right in saying 1 5/8" would be fine to use for the entire cage?

Thanks for any input!

Ben

Edited by Sawyer, 08 March 2016 - 10:43 PM.