I've never been very happy with the off-centring that results from engine-mounting stands that pick up over towards the alternator mounts, and these plate-type fittings seem to put one hell of a lot of load on mounting points that are rather close together, and all in the same plane.

Sure, they work, everyone uses them, end of story.

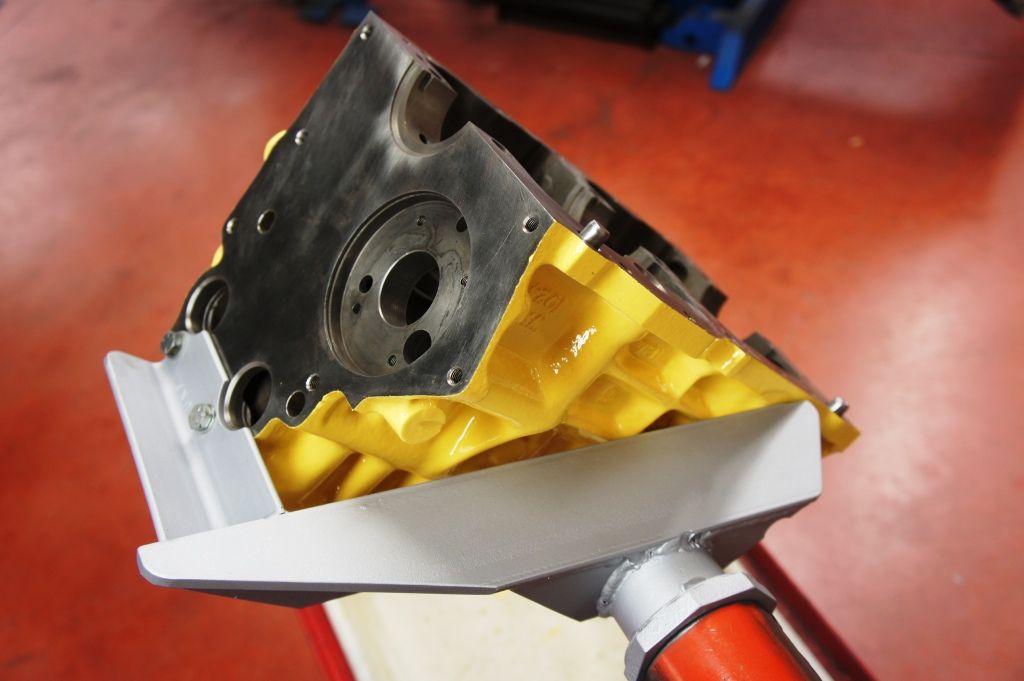

But if you're an OCD sufferer like me and would rather 1) reduce the loads on your mounting bolts by making the fixings farther apart, 2) reduce those loads to mostly shear by using perpendicular mounting surfaces, and 3) end up with an engine that you can work on as if it were in the car - the right way round - then you might like to consider making one of these.

No, it won't work on injected motors, it needs the fuel-pump orifice.

No dimensions supplied, tricky to measure, but if you're capable of making it then you can probably work out the sizes for yourself.

Suggest you wind up the MIG and get some decent welds, no pigeon-turds.

I used 70x70x7 angle for the main spar, 40x40x4 for the side angle, the pivot pipe is 60 OD and 3.5 wall, the fancy hex is 80 AF and it's actually just cut off an octagonal steel plumbing fitting.

The 60mm pipe-size fits all the Clarke/Sealey etc engine-snatds and clones as far as I know, mine is 30+ years old and I have used this size to make tens of different adapters and jigs.

The key point on the fuel-pump attachment is to make a steel plug about 10mm high and a snug fit in the orifice - about 30mm diameter on mine ; this is plug-welded from the outside, in-situ, and will take all the shear-loading off the two 5/16 UNC fuel-pump bolts.

I scalloped the side-angle that picks up on the two 5/16 UNF tie-bar fixings so that I could do the core-plugs at the same time.

In use it has proved spectacularly satisfactory, and the balance remains acceptable both with block+crank only, block/crank and gearbox, then plus clutch, then plus head.

Edited by MontpellierVanMan, 02 June 2016 - 08:49 PM.