Again hello to all you good mini people and Spi lovers

just nudging along with my build,

getting to putting the box back on

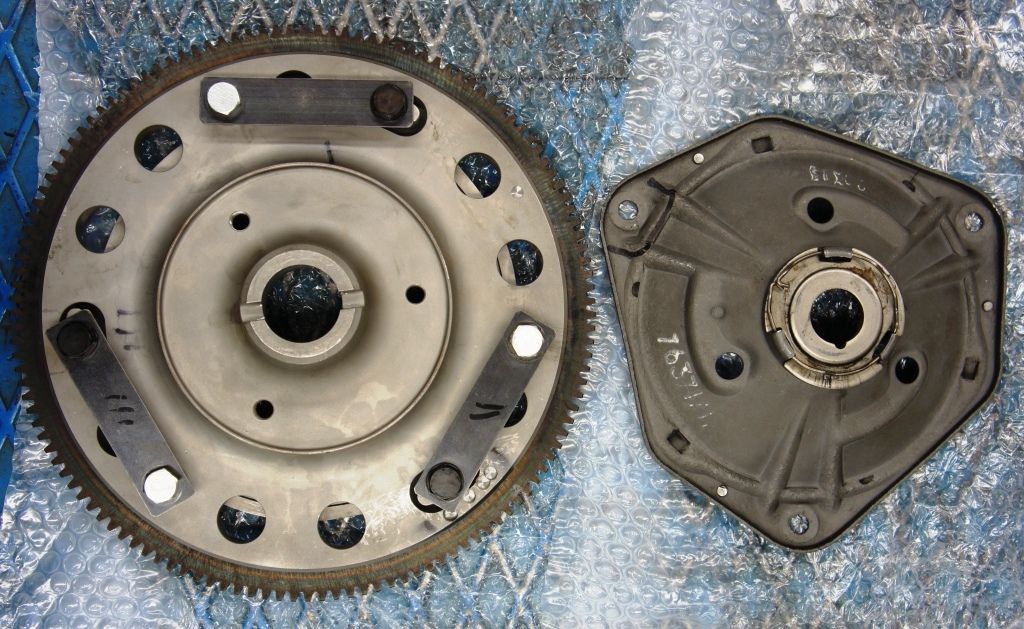

and then the flywheel and clutch

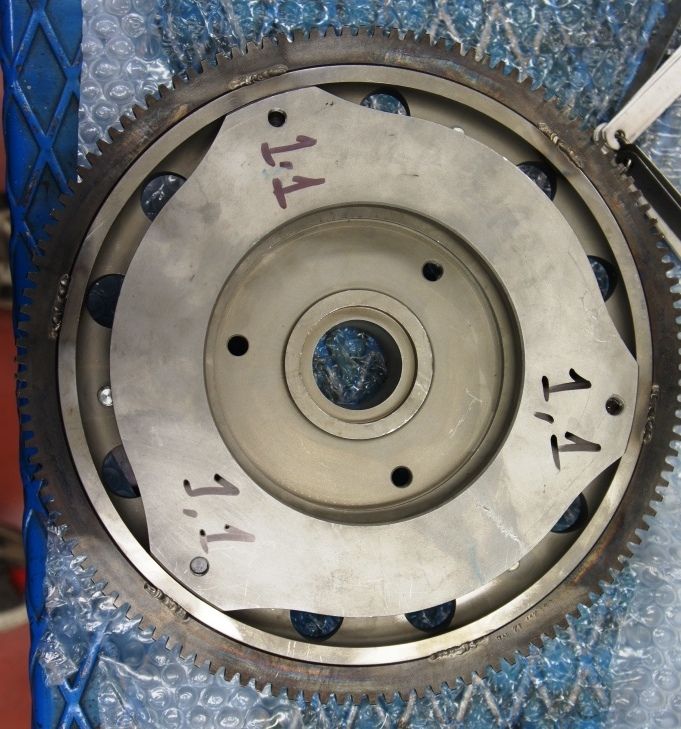

As you can see from the pictures the original Spi flywheel is balanced with some serious little holes drilled out in strategic places

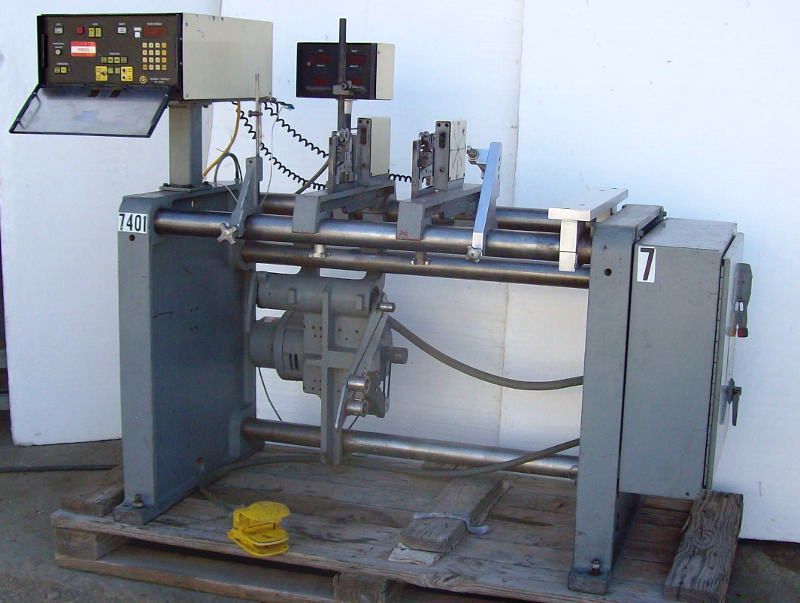

As I understand I need to mount the new Minispares steel flywheel to the other clutch parts and get it dynamically balanced.

As my local machinist is not likely to be familiar with the Mini clutch where exactly is / are the best spots to drill (do people add weight, I don't think they do, do they)

I want to be able to give the machinist the maximum amount of info possible, which can be a bit tricky as we often don't speak the same language

if anyone has pictures or drawings of a balanced billet steel Spi flywheel I would be very very grateful

as usual thanks so much to you all for your enthusiasm, knowledge and for sharing

let's hope I can get this engine together