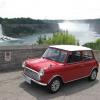

I Run a 1991 998cc Japanese Export Mini in Ontario, Canada since 2009.

Had 13 Minis over the years in the UK before that from 1992 to 2005.

Over the last 4 years I have replaced the front wheel bearings twice. The car only comes out in the summer and rarely sees rain.

So high mileage is not a problem.

The first time I fitted complete made up hubs from Mini Sport UK. Complete with ball joints and bearings fitted. The idea being that I just swap the hubs over with the originals.

So after a couple of years minimal use I had bearing noise one side and a ball joint gone on the other.

Again trying to save time I stripped my original hubs (now spare) to the car and fitted new Mini Spares bearings and balljoints.

After a couple of summers the bearing growl is back and on the other side a CV boot has split. These components having only seen minimal use.

So what am I doing wrong?!

I don't really want to strip all this out again in a couple of years.

I intend to fit new brake calipers (originals 29 years old and seizing), discs (warped) pads (new pins and shims), bearings (mini spares, Timken ones sold out), Front flexi brake hoses, New CV joints (old ones have bad wear patterns). New castle nuts and cone washers.

So I am wondering if the drive flanges have knocked the bearings out. The surfaces have wear, but not a thick groove. I am hesitant to rebuild the original hubs as they are pretty scored where the bearing runners go. My spare hubs which are newer and in better condition have some marks inside where I was not careful enough punching out the old bearings.

I think for peace of mind I will also fit new hubs and drive flanges!

Has anyone also had bearings fail after low mileages/use?

I have heard many causes of failure.

Bearing quality, Grease quality. Not having the metal oil seal spacer ring fitted (shown as no longer required).

Not torqued enough (I done mine to 200 lb/ft)

I Would be interested to hear your thoughts and ideas.

What methods and parts do you use? What bearing grease would you recommend?

I enjoy working on the car, but have time and money pressures like us all. But there has been a real drop in quality of parts over the last 10-15 years.

I even used to argue with Rover dealers in the UK that I wanted Rover OE parts and not Unipart Items. But those days are long gone!!

Thanks in advance. Mark.

Edited by minimarkybecks, 16 July 2020 - 07:48 PM.