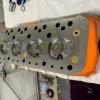

Garret T3 Rebuild [continued]

Well I am impressed by the eBay seller for delivering the kit quickly. After opening the kit it looked mainly correct. Then when assembling many things were found to be incorrect. I will send the supplier some info regarding the incorrect parts but it cost £32 and I have managed to rebuild the Turbo. I never expected it to all be correct.

Things that could be used -

Rings for sealing the shafts before compressor and turbine wheels.

Bolts for compressor housing.

Centre bearings.

Circlips.

Compressor housing seal to main body.

What could NOT be used -

Main large compressor housing seal ring.

Brass oil guide and wear plate.

Centre bearing located in brass oil guide

Bolts for compressor housing to main body.

Heat shield at turbine end [could have been used but was a different shape]

less than 50% of the kit is usable.

The good news is nearly all components that were removed from the old Turbo were in very good condition. Other than a huge amount of charred cooked oil in there it really didn't look that bad when stripped.

Im actually pretty happy with the end result. I have used compressed air blown on the compressor wheel and ran it as fast as possible. No issues noted. Is it balanced. Probably not. I took great care marking the compressor wheel nut before removal. The lines scribed on the nut were perfectly inline with the ground section on the compressor wheel. I did not remove the turbine wheel from the shaft. I aligned the scribed marks with the flat on the compressor wheel when rebuilding so should all be back as original.

IMG_2474.JPG 34.8K

1 downloads

IMG_2474.JPG 34.8K

1 downloads

IMG_2476.JPG 30.59K

0 downloads

IMG_2476.JPG 30.59K

0 downloads

IMG_2477.JPG 57.74K

0 downloads

IMG_2477.JPG 57.74K

0 downloads

IMG_2478.JPG 36.22K

0 downloads

IMG_2478.JPG 36.22K

0 downloads

IMG_2483.JPG 50.47K

0 downloads

IMG_2483.JPG 50.47K

0 downloads

IMG_2485.JPG 53.89K

0 downloads

IMG_2485.JPG 53.89K

0 downloads

IMG_2486.JPG 41.16K

0 downloads

IMG_2486.JPG 41.16K

0 downloads

IMG_2487.JPG 37.52K

0 downloads

IMG_2487.JPG 37.52K

0 downloads

IMG_2489.JPG 34.5K

0 downloads

IMG_2489.JPG 34.5K

0 downloads

IMG_2490.JPG 35.59K

0 downloads

IMG_2490.JPG 35.59K

0 downloads

It will be interesting to see how well it works. Would I recommend home rebuild using eBay kits.. Not really. As i said I am actually happy with the end result. I honestly think it will work ok. For how long is another big question..

ADDED NOTE: I contacted the eBay seller and explained the issues. They instantly responded and have apologized for the inconvenience and offered a 50% refund. Total cost to rebuild T3 was less than £20. That includes ordering all new fixings and the service kit after refund.

Edited by Project_1275_GT, 06 December 2020 - 10:48 AM.

IMG_2401.JPG 56.83K

5 downloads

IMG_2401.JPG 56.83K

5 downloads IMG_2406.JPG 48.74K

2 downloads

IMG_2406.JPG 48.74K

2 downloads IMG_2404.JPG 50.12K

0 downloads

IMG_2404.JPG 50.12K

0 downloads IMG_2408.JPG 49.3K

0 downloads

IMG_2408.JPG 49.3K

0 downloads