Water Injection System [Home made version]

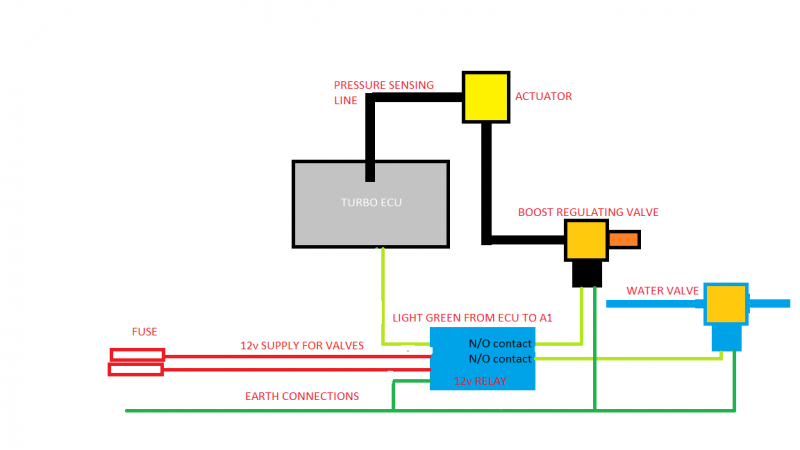

I have got all the original Metro Turbo parts that most people discard as they are not really needed. Turbo ECU that controls only the boost pressure modulation, this senses the pressure of the system and uses a solenoid operated valve to bleed off some pressure. This is set to trigger around 4 PSI [also 4500 RPM]. The waste gate actuator is also set to operate at around 4PSI. So the original system allows the PCR valve to bleed off pressure keeping the wastegate closed up to the max 7.5 PSI [This is oscillated at 12 Hz setting]. Result is a slower more controlled boost. Knowing how this system works I intend to use the same ECU control but rather than the output from it direct to PCR valve it will operate a relay. The relay will then operate 1 - the bleed valve for pressure. 2 - The opening of the water valve. This should result in the engine running without water cooling up to 4 PSI, Then the bleed valve and water valve will open.

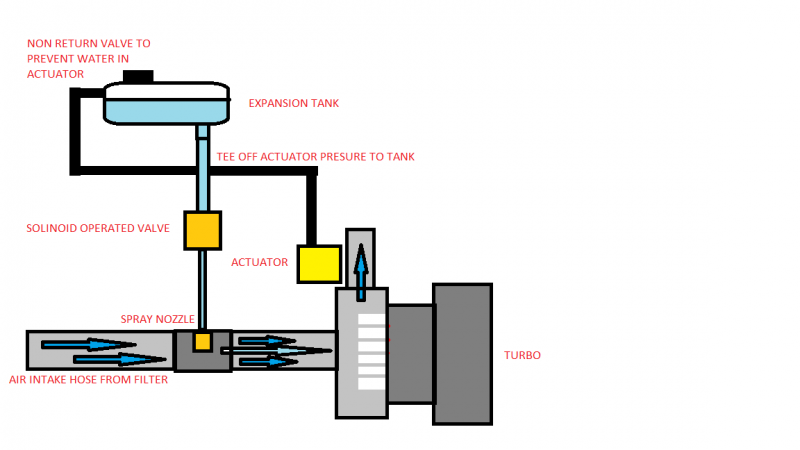

I will setup a test rig for this just to test water flow through the nozzle and pressure required to get good atomization, I intend to place the water nozzle in the inlet to the Turbo as some benefits have been noted to lower the Turbo temperature. There is some concerns regarding water droplets damaging the compressor wheel. But no confirmed detail. So i will test it. I intend to install two very basic temperature sensors - 1. at the inlet area to the turbo. 2 - in the inlet manifold. This will give me some info on actual temps before and after.

The reservoir for the water will be an old mini expansion tank, the pressure for the system i hope to use from the boost pressure. This is my main challenge to get a atomized spray of water at low pressure. If more pressure is required I will add a pump. Really hope i can do it without. The solenoid operated valve from the ECU will prevent syphon of water. The expansion tank is only small but i hope enough. It should only be used over 4500 RPM and 4 PSI boost.

I will also install a sensor to check water level in the expansion tank. If the level runs low the relay operating both PCR valve and the water feed valve will be disabled. This will result in the boost being limited to 4 PSI. Hopefully this will prevent problems with running out of water and running high boost.

If all of the above works I hope to be able to run slightly higher boost than normally possible on a higher compression engine.

BASIC LAYOUT OF THE SYSTEM

This is not showing water level sensor. I have yet to work out the best sensor type. It will simply involve another relay preventing the live feed from the ECU to the valve control relay.

Edited by Project_1275_GT, 01 February 2021 - 07:37 AM.